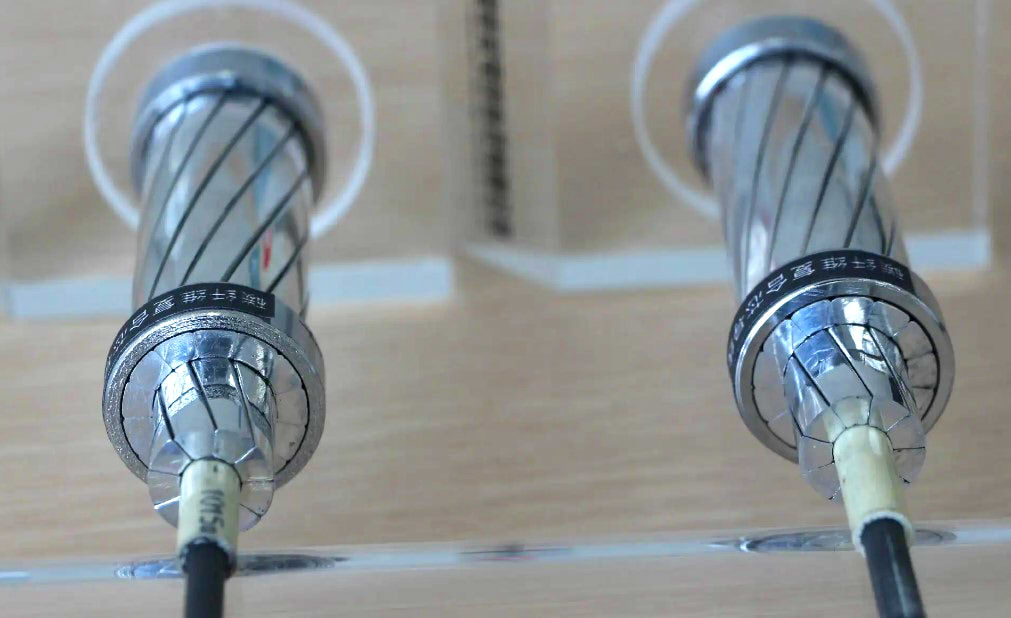

Composite Core Aluminum Conductor is a conductor with carbon fiber core. It's a new kind of driver for airlines of transmission. This type of cable is light, stretch resistant, thermally stable and corrosion resistant. It is especially suitable for use in coastal areas, mining areas and other corrosive environments where the driver is prone to dancing.

Composite core aluminum conductors can meet the requirements of resource-saving and environmentally friendly power network construction. Composite core aluminum conductor cables are a new product that replaces traditional ACSR and AAC conductors in electrical systems around the world..

Advantages of Composite Core Aluminum Conductors

High Strength and Light Weight

The tensile strength of ordinary steel wire is 1240-1410 Mpa. While, Carbon fiber core has twice the tensile strength of steel wire and weighs only a quarter as much. And aluminum composite core conductors of the same size weigh between 10% and a 20% less per unit length than conventional ACSR conductors. This makes it possible to reduce the number of towers by about one 16%, while reducing its footprint on the land..

High Electrical Conductivity and Low Transmission Losses

The cross-sectional area of composite core aluminum conductors is 1,29 times greater than that of conventional cable conductors. Composite core aluminum conductors do not suffer from magnetic losses caused by the steel material or the thermal effects of electricity. As a result, has a lower operating temperature for the same load and reduces transmission losses around the 6%.

Composite core aluminum conductor also has a smoother appearance than ACSR round aluminum cable due to the trapezoidal shape. Besides, this improves the roughness of the cable surface and thus reduces corona losses.

Low Bow Collapse

Composite core aluminum conductors have significantly less bow sag compared to conventional cable conductors. This reduces the insulation space of the overhead line and increases the safety and reliability of the conductor's operation..

Corrosion Resistant

ACSR's aluminum wire and steel core are exposed to air for long periods of time. As a result, the surrounding environment can corrode the metal material.

The composite carbon fiber core of the composite core aluminum conductor does not rust and is corrosion resistant. Overcome corrosion problems stranded wires galvanized steel. It also prevents galvanic corrosion problems between aluminum wires and galvanized steel wires.. How best to solve the problem of aging overhead conductors in long-term operation, its service life is twice that of ordinary cables.