Cable Conductor

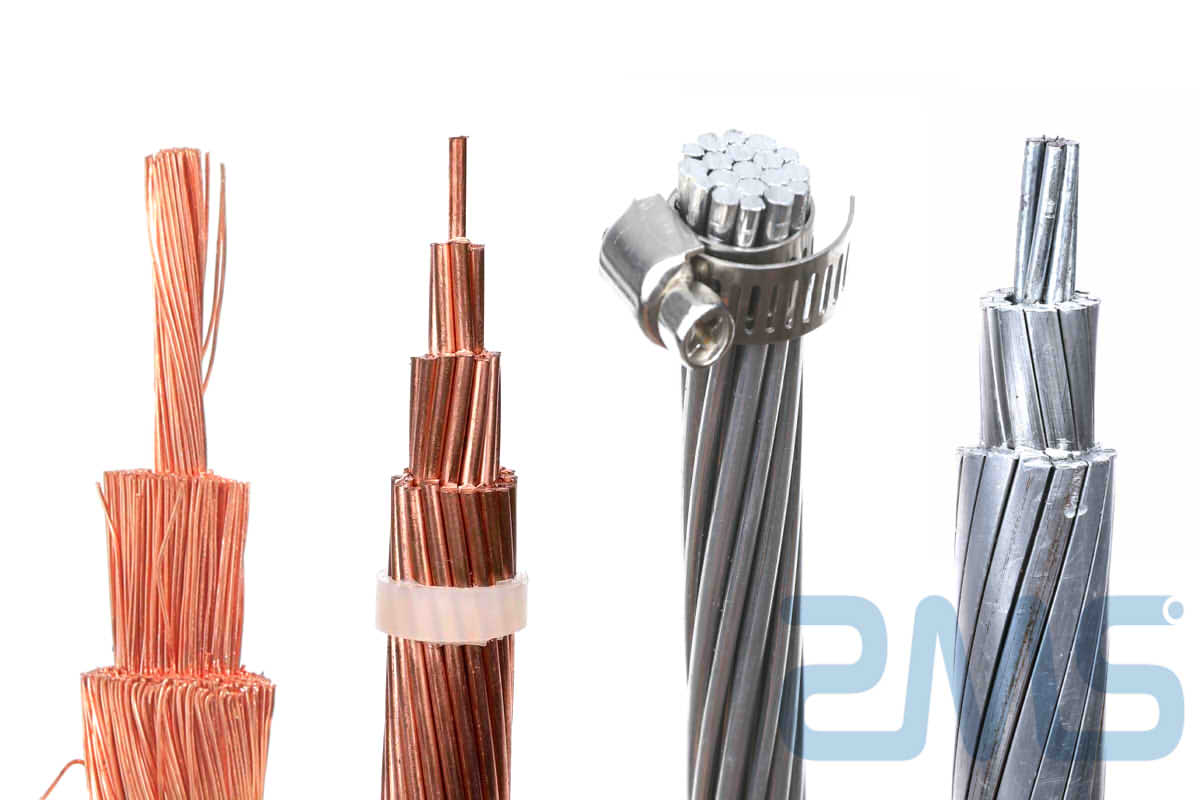

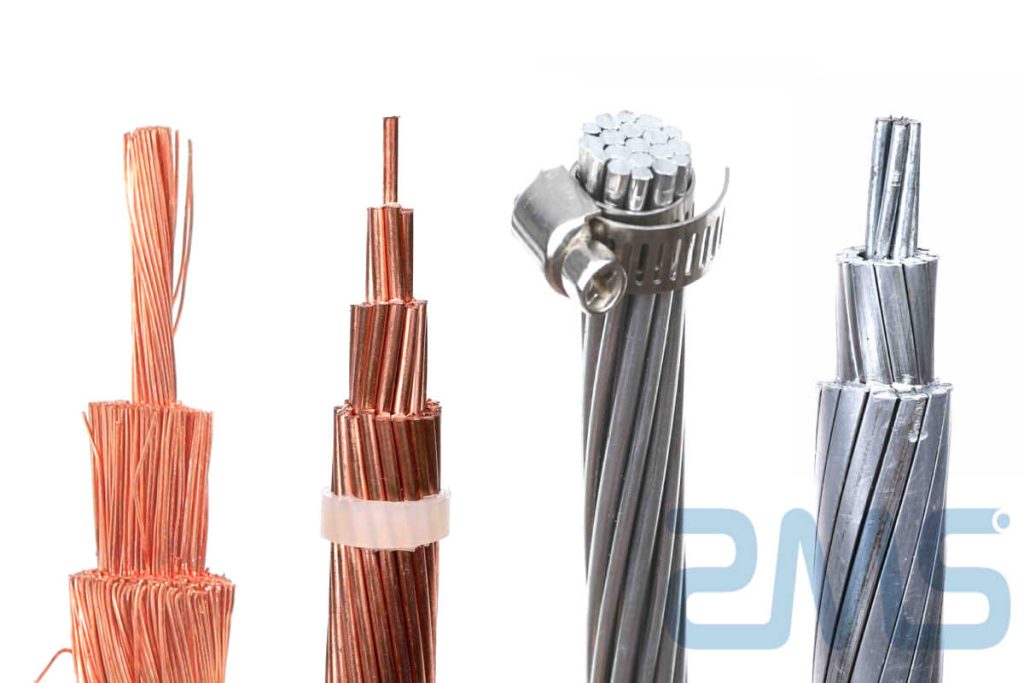

The cable conductor is the main part of the cable to carry current. Due to the high concentration of free electrons in metals and their high electrical conductivity, cables often use metallic conductors. The most common electrical conductors are copper., aluminum and aluminum alloys.

ZMS uses high quality cable conductors, as oxygen-free annealed copper, oxygen-free aluminum and series aluminum alloys 8000. They have few impurities and low strength, which guarantees a transmission of electricity with few losses. The complete process of production in ZMS, from the selection of materials to the final delivery of the product, is subject to strict quality control.

Types of Electrical Cable Conductors

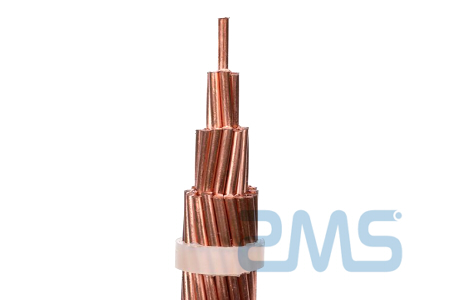

Copper wires have high electrical conductivity, with a DC resistivity of approximately 1.72×10-6 Ω·cm a 20°C. ZMS copper cable use high-precision oxygen-free copper that meets international standards. has good flexibility, Low resistance, low power transmission losses and long-term service life.

ZMS can also offer tinned copper cables, which gives copper greater resistance to corrosion and oxidation. ZMS copper conductor cable products include: bare copper wire, tinned copper wire, Shielded and armored copper cable, etc.

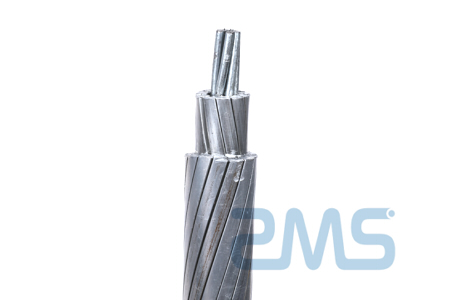

Aluminum wires have a resistivity of approximately 2.82×10-6 Oh·cm. Although aluminum is less conductive than copper, it is less dense and lighter, which greatly facilitates the transport and installation of the cables.

ZMS aluminum cables are more economical in price, often several times cheaper than copper cables. ZMS aluminum cable products include: Aluminum Bare Aerial Cable, Pre-assembled aluminum cable for fitting, aluminum concentric cable, etc.

As the main material of aluminum alloy conductors is aluminum, have very similar physical properties. Aluminum alloy improves the tensile strength of pure aluminum and can support a self-weight of 4000 m in length. The main aluminum alloy conductors used for cables are those of the AA8000 series, having a non-aluminum content of about 0,8 a 1,5%.

The conductivity of aluminum alloys is the 61,8% that of copper IACS and the load capacity is the 79% of the copper. The price of aluminum alloy cables is between a 15% and a 30% lower than copper cables. ZMS effectively improves corrosion resistance, creep resistance, the tensile strength and elongation of the conductor by adding special components, like rare earths.

Composite conductor has unique performance thanks to advanced coating and welding technology. This reduces costs and increases strength without compromising transmission performance.. There are also reinforced composite conductors, They typically use a steel core to increase their strength. The ZMS Composite Cable range includes: copper clad aluminum cable, Aluminum braided cable with steel core, HTLS air conductor, etc.

Comparison of Electrical Conductors of Cables

| Driver Types | ||||

| Copper | Aluminum | Aluminium alloy | ||

| Relative value of charge flow | % | 100 | ~77.5 | ~77.5 |

| Relative value of conductivity | % | 100 | 61~63 | 59~61 |

| Energy consumption | Smaller | Mayor | Mayor | |

| Relative value of DC resistance | % | 100 | ~165 | ~165 |

| Connection reliability | oxidation resistance | Alta | Baja | Baja |

| Creep resistance | Alta | Baja | Media | |

| Wear by micro-action | Little | Grande | Grande | |

| intermetallic compound | No | Yeah | Yeah | |

| corrosion resistance | Alta | Baja | Media | |

| construction performance | Tensile strength/MPa | 240 | 160 | 110 |

| Allowable tensile force/Mpa | 70 | 40 | 28 | |

| cable outer diameter | Smaller | Mayor | Mayor | |

| Multiple of the radius of curvature | ≥15D | ≥15D | ≥7D | |

| Terminal connection process | Simple | Complicated | Complicated | |

| Relative weight of the cable | 100% | 80% | 80% | |

ZMS Lead Wire Processing

Materials selection: ZMS uses high quality materials in the manufacture of its cable conductors.. The careful selection of materials guarantees the quality and durability of the cables.

driver preparation: In this stage, cable conductor is prepared. Impurities are removed and a heat treatment is performed to improve the mechanical properties of the conductor..

Drawn: Wire drawing is a mechanical stretching process in which the diameter of the conductor wire is reduced to improve its strength and ductility.. And ZMS, High precision wire drawing equipment is used to ensure the exact diameters and tolerances required for each Type of cable.

Covering: ZMS uses a variety of coatings to protect the conductor from corrosion and abrasion.. The coatings are of different materials, like polymers, metals and alloys.

Braided: In this stage, several conductor strands are twisted together to form a solid conductor. Braiding provides mechanical resistance to the cable and improves its load capacity.

All these processes are carried out under rigorous quality controls to ensure that the electrically conductive ZMS meet the quality and safety standards required by the industry..

Choose Copper or Aluminum Cables?

Since aluminum conductors are much cheaper than copper conductors, Is it feasible to use all aluminum cables instead of copper?

Copper conductors are heavier than aluminum conductors.. The specific weight of copper is 8.9 g/cm3 and that of aluminum is 2.7 g/cm3. This means that a copper conductor is 3,3 times heavier than an aluminum one with the same specifications.

Nevertheless, the electrical conductivity of aluminum is only the 61% of the copper. This means that the cross section of a conducting aluminum is a 61% greater than that of a copper conductor for the same current. So, in terms of driver weight, to have the same current carrying capacity, the weight of copper is about twice that of aluminum. Besides, the price ratio between copper and aluminum is approximately 3,5, so that an equivalent copper conductor costs seven times more than an aluminum one.

Of course, this simple cost comparison does not say it all. The rise of the insulation materials, Cladding and armor can reduce the price advantage of using aluminum conductors. In this case, the price advantage of aluminum cables compared to copper cables is not significant, since the cost of the conductor is only a part of the total cost of the cable.

So, when choosing whether to use copper or aluminum as conductor for cables, it is important to consider the price, the weight, conductivity and other factors to make a proper choice.

ZMS Service Commitment

And ZMS, We pride ourselves as a specialist cable manufacturer that offers a wide variety of high quality products and exceptional service to our customers.. We are committed to providing custom solutions to your cabling needs., and we will work with you to make sure your project is a success. Our highly trained team is always ready to help you with any questions or concerns you may have.. Besides, we strive to maintain competitive prices and fast delivery times to ensure your satisfaction. Con ZMS, You can be sure that you will receive the best service and electrical cable products on the market..

Know More about Conductor Cable