The types of cable conductors are classified according to their material, its shape and use. Different applications require the use of different types of conductors. Now, ZMS walks you through the various electrical conductors.

Table of Contents

Cable Conductor Materials

In the world of electricity and power transmission, the materials of the cable conductors play a fundamental role. These materials determine the efficiency, conductivity and safety of electrical transmission.

copper cable conductors: a classic option

Copper has been widely used as a conductive material in the electrical industry for decades.. Its physical and chemical properties make it a reliable and efficient choice for power transmission.. Los copper wires are known due to its high electrical conductivity, which means they allow current to flow with hardly any resistance.

Besides, copper is resistant to corrosion and has an excellent ability to withstand high temperatures. These characteristics make copper conductors ideal for applications where high current carrying and increased durability are required..

The benefits of aluminum conductors

Although copper remains the preferred choice in many applications, aluminum offers a number of benefits that make it attractive in certain settings. Aluminum is a lighter metal than copper., making installation and cable management easy. Besides, it is less expensive than copper, which can result in significant savings on large projects.

Nevertheless, it is important to note that the aluminum conductors require a larger size compared to copper ones to achieve the same current capacity. They may also be more susceptible to corrosion., therefore extra precautions must be taken in environments prone to oxidation.

Other materials used in cable conductors

In addition to the materials mentioned above, there are other less common options used in cable conductors. These include copper clad steel, galvanized steel and aluminum alloys, among others. These materials are used in specialized applications where specific properties are required., as tensile strength, flexibility or weather resistance. Each material has its advantages and disadvantages., and your choice will depend on the particular needs of each project.

Cable Conductor Shape

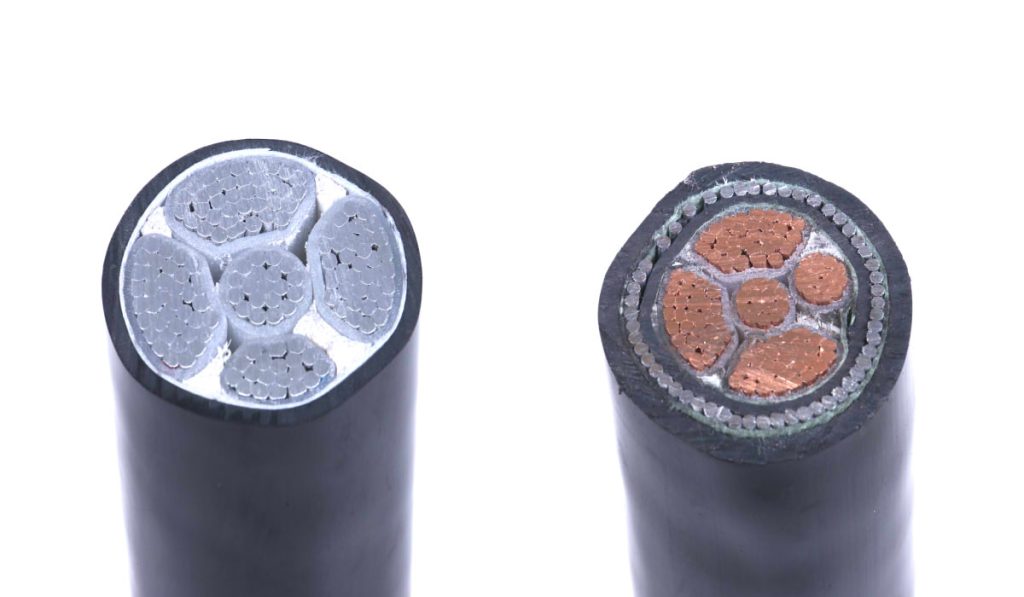

According to the structure and shape of the conductor, conductor types of cables can be divided into round conductor, sector-shaped conductor and special-shaped conductor.

round conductor

The round conductor is the most common and widely used type in electrical applications.. Its cylindrical shape provides good flexibility and ease of installation. Besides, this type of conductor for cables offers greater resistance to mechanical stress and has a higher current capacity. It is used in a wide range of applications, from power distribution systems to industrial facilities.

sector wires

A sector cable is a cable in which the conductors are arranged in the shape of a sector. Its conductors are usually made up of multiple copper wires joined by braiding. The special sector-shaped cable construction in the conductor arrangement provides greater flexibility and bendability for applications where twisting or bending is necessary. Cables with sector conductors are commonly used in machinery and equipment, industrial automation and other areas.

Special Shape Lead Wires

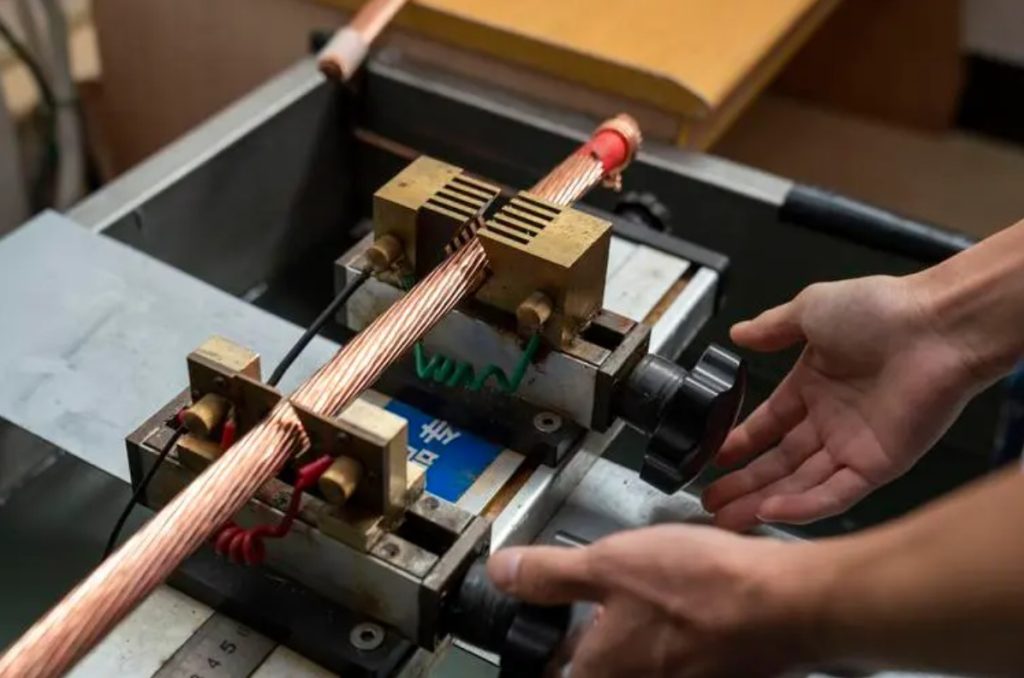

In recent years, with the development of cable manufacturing technology, many in the industry have begun to use specially shaped conductors to improve the compression ratio of the conductor. By improving the compression coefficient of the conductor, it is possible to effectively reduce the outer diameter of the cable, thus saving the amount of materials used. This allows an average reduction of the outer diameter of the rope by more than 5%.

The process of manufacture of cables with conductors Special shapes involve twisting and co-forming the cable strands using a unique process. This not only improves the electrical performance of the finished cable, but it also makes it aesthetically more attractive.

Besides, manufacturing cables with specially shaped conductors does not require major modifications to existing equipment and production processes, only higher requirement for mold tools is required during the manufacturing process.

Specially shaped conductor cables are structurally stable and more conducive to extrusion of insulation. They are especially for medium and high voltage electrical cables.

Cable Conductor Class

according to international standards, the conductors of the cables can be divided into the following classes:

solid driver

class drivers 1 they are solid conductors, namely, the conductor is made up of a single wire. Solid copper conductors will be of round section. and the drivers of 25 mm and above are only used for special cables and not for general cables.

For solid aluminum conductors, the cross section will be circular for the sizes of 16 mm from the lower. 25 mm and above will be circular for unipolar cables, and in case of multicore cables, may be circular or have a cross section formed.

stranded conductor

To improve the flexibility or bendability of cables, conductors with a larger section are made up of several smaller diameter wires wound together. Cable cores made up of multiple stranded wires have good flexibility and higher bendability. When the core folds, the two inner and outer parts of the core axis can be displaced and mutually compensated, without causing deformation in the conductor.

class drivers 2 they are twisted conductors and have circular sections, tile-shaped and other shapes, which increases the flexibility of the cable. Its tightening coefficient (or fill ratio) can be higher than 0.9. Cables with stranded conductors are a representation of the cable mill's production capacity level and are the most commonly used cable conductors.

Conductor flexible

class wires 3 Y 5 are general purpose soft conductors. Usually refers to conductors made up of multiple fine wires twisted together. They have the soft benefits that drivers in the class do not have 2, and can be used as general moving cable conductor.

class drivers 4 Y 6 are extra soft conductors used for special moving cables, as the branch lines of welding machines.

Conclusion

Careful choice of cable conductor material and shape is essential to ensure optimum performance and longevity in any electrical project..

Materials such as copper and aluminum offer different advantages and electrical properties, and their selection will depend on factors such as conductivity, corrosion resistance and cost. Besides, the shape of the driver, either round, sector shaped or special shaped, has implications for flexibility, bendability and ease of installation.

By considering the specific needs of each project, like charging current, environmental conditions and flexibility requirements, the right cable conductor can be chosen to optimize performance and extend cable life, thus guaranteeing an efficient and safe electrical transmission.