In electrical design and technical reforms, scientific selection of cross-sectional area of electrical conductors is crucial. Experienced electricians will calculate the current according to the electrical load to decide the cross-sectional area of the wires.. There are also some electricians who will choose the cross-sectional area of the wires based on a mnemonic.. Today ZMS will share with you a scientific and simple method to select the cross-sectional area of cables.

Table of Contents

- Transverse Area of Electrical Conductors

- Selection of Cross-sectional Area of Electrical Conductors according to the Long-Term Allowable Current

- Selection of Cross-sectional Area of Electrical Conductors according to Economic Current Density

- Selection of Transverse Area of Electrical Conductors according to the Voltage Drop in the Electrical Network

- Selection of Cross-sectional Area of Electrical Conductors according to the Thermal Stability Coefficient

- Resume

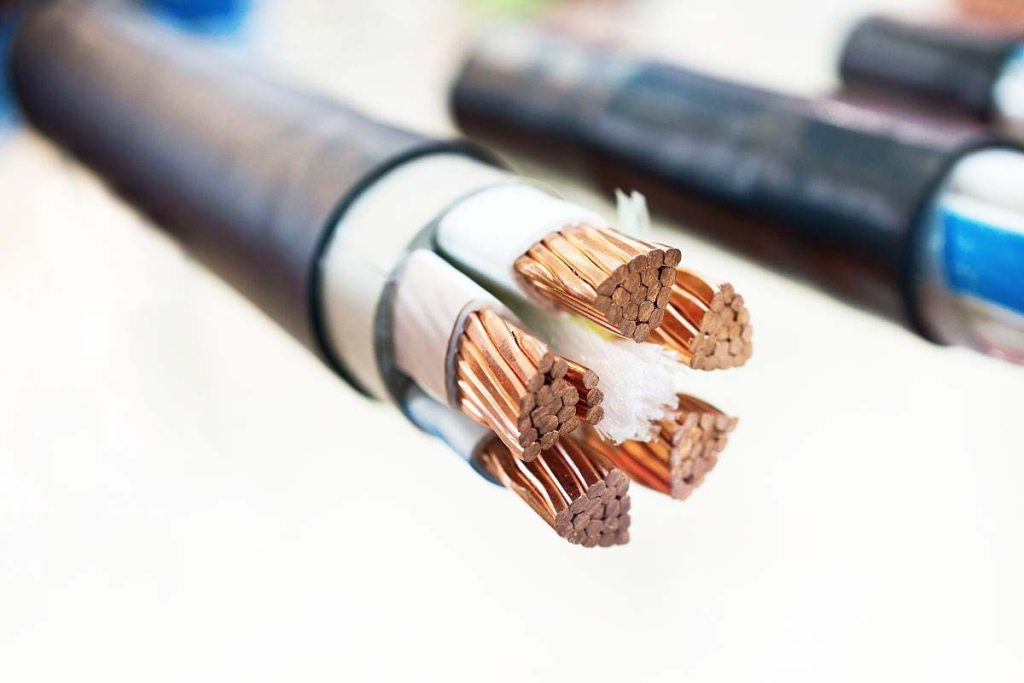

Transverse Area of Electrical Conductors

The cross-sectional dimension of a cable generally refers to the cross-sectional area of the cable conductor.. In general, the larger the cross-sectional area of the cable, the greater the driving ability of the driver and, but still, the greater the energy transmission capacity.

Nominal Cross Area

The nominal cross-sectional area of a cable establishes a numerical value for the specific size of the conductor, but is not affected by direct measurements. This parameter refers to the designated value on cable products, which is used to express the cable specifications. It is simply a code or name of this specification, facilitating documentation and production management during the manufacturing process. It facilitates the selection and orientation of production and electrical design for users and designers.. Nevertheless, no direct measurement of its actual cross-sectional area is required.

Cross Design Area

The cross-sectional area of cables selected for low-voltage distribution systems should not be less than the design cross-sectional area value. Before applying a cable, Samples must be taken to inspect their cross section and the electrical resistance of each conductor. The variable directly related to the load capacity of the cable is the electrical resistance of the conductor. (R), not the actual cross section of the conductor. When we evaluate the cross section of a cable or the nominal area, we are evaluating its electrical resistance, not measuring its actual cross-sectional area.

Real Transverse Area

The actual cross-sectional area refers to the geometric area of the cable conductor. For cable manufacturers, determine the size of the electrical conductor for a specific nominal cross section that meets the standard requirements does not mean that the actual cross section must be greater than or equal to the nominal cross section, but the design cross section (electrical cross section) under this nominal cross section must meet the standard requirements, namely, Whether the electrical resistance meets the standard requirements. When designing a driver, if a material with a high conductivity is chosen, then the actual cross-sectional area may be less, while if a conductor with a low conductivity is chosen, the actual cross-sectional area should be larger.

Conductor Cross-sectional Area Requirements in Cable Product Standards

Currently, Product standards of major cable standards systems use nominal cross-sectional areas or specification codes to distinguish between different conductor cross-sections.. For example, IEC standards (IEC60227, IEC60245, IEC60502, etc.) and European standards (EN50525, etc.) use nominal cross-sectional areas (in square millimeters) as codes for different specifications of conductors of different sections. In this case, The evaluation of different cross section specifications is based on the conductor resistance value, not in the actual measurement of the cross-sectional area of electrical conductors.

Selection of Cross-sectional Area of Electrical Conductors according to the Long-Term Allowable Current

To ensure the safety and life of the cable, The temperature of the cable after energizing should not exceed the specified permissible long-term working temperature, being of 70 degrees Celsius for cables with polyvinyl chloride insulation and 90 degrees Celsius for cables with cross-linked polyethylene insulation. According to this principle, You can consult a table to select the cable.

Example: A transformer capacity of a factory is 2500 kVA, with feeding 10 kV. If you use a cross-linked polyethylene insulated cable lying on a bridge, What cross-sectional area of electrical conductors should be chosen?

Paso 1: Calculate rated current 2500/10.5/1.732 = 137 A

Paso 2: Consult the cable selection manual to know:

YJV-8.7/10KV-3X25 has a rated current of 120 A

YJV-8.7/10KV-3X35 has a rated current of 140 A

Paso 3: Here YJV-8.7/10KV-3X35 cable is selected since its rated current is greater than 137 A, theoretically it would meet the requirements.

Use: This method does not consider dynamic and thermal stability requirements.

Selection of Cross-sectional Area of Electrical Conductors according to Economic Current Density

The cross-sectional area of the cable affects the investment in the line and the losses of electrical energy. To save investment, the cross-sectional area of the cable should be as small as possible, but to reduce electrical energy losses, the cross-sectional area of the cable should be as large as possible. Considering these considerations, a reasonable cable cross-sectional area is determined, called economic cross-sectional area, and the corresponding current density is called economic current density.

Method: Consult a table to obtain the economic current density based on the annual operating hours of the equipment (unit: A/mm).

Example: The nominal current of the equipment is 150 A, with an annual operating time of 8000 hours, What cross-sectional area of copper cable should be chosen?

According to the table of economic current densities of conductors, depending on the maximum usage time at full load per year (hours):

| Driver Material | Hours of Use at Full Annual Load Tmax | ||

|---|---|---|---|

| Less than 3000 | 3000~5000 | More of 5000 | |

| Aluminum wire, Aluminum Wire with Steel Core | 1.65 | 1.15 | 0.9 |

| Copper wire | 3.00 | 2.25 | 1.75 |

| Aluminum Cable with Aluminum Core | 1.92 | 1.73 | 1.54 |

| copper wire | 2.50 | 2.25 | 2.00 |

According to the table, con 8000 hours, the economic density is 1.75 A/mm².

S = 150/1.75 = 85.7 A

Conclusion: According to cable specification, we can select a cable cross-sectional area of 95 mm².

Selection of Transverse Area of Electrical Conductors according to the Voltage Drop in the Electrical Network

When we select the cross-sectional area of the wire according to the first and second methods, if the cable is too long, There will be a certain voltage drop during operation and startup. If the voltage on the equipment side drops below a certain range, may cause heating of the equipment.

According to him “Electrician's Manual”, The voltage drop on a 400V line must not be less than 7%, namely, 380Vx7%=26.6V.

Formula to calculate voltage drop (here only the purely resistive voltage drop is considered):

∆U=I×ρ×L/S

S=I×ρ×L/∆U

∆U: Voltage drop I: Nominal equipment current ρ: S conductor resistivity: Cable cross-sectional area L: Cable length

Example: For equipment with a nominal voltage of 380V and a nominal current of 150A, using a copper wire (ρ=0.0175Ω.mm/m), with a required voltage drop less than 7% (∆U=26.6V), and a cable length of 600 metros, What cross-sectional area of cable S should be chosen?

According to the formula S=I×ρ×L/∆U=150×0.0175×600/26.6=59.2mm².

Conclusion: A cable cross-sectional area of 70mm² is selected.

Selection of Cross-sectional Area of Electrical Conductors according to the Thermal Stability Coefficient

Selection of the cross-sectional area of electrical conductors according to the thermal stability coefficient implies choosing the cross-sectional area of the cable according to the magnitude of the short-circuit current.

For 0.4KV cables protected by air switches, Generally cables can meet thermal stability requirements and do not need to be verified using this method.

For 6KV cables or more, after selecting the wire cross-sectional area using the above methods, It is necessary to verify whether it meets the thermal stability requirements using the following formula. If you don't comply, a larger cross-sectional area should be selected.

Formula: Smin=Id×Ti/C

Of: Circuit breaker breaking time, taken as 0.25s

C: Cable thermal stability coefficient, taken as 80

Id: System three-phase short-circuit current value

Example: If the system short circuit current is 18KA, How is the cross-sectional area of the cable selected??

Smin=18000×√0.25/80=112.5

Conclusion: If the system short circuit current reaches 18KA, even if the rated current of the equipment is small, the cross-sectional area of the cable should not be less than 120mm².

Resume

In summary, in practical wiring application, It is necessary to carefully evaluate whether the selection of cross-sectional area of electrical conductors meets the project requirements according to actual use needs.. Besides, You can also directly communicate your specific needs to the electrical cable supplier, who will help you make the right decision.