Construction and Engineering Cable

The construction and engineering cable of ZMS can provide reliable electrical power for public buildings, commercial and industrial, as well as for engineering and construction projects. Different types of site cables can be used for mains connections, fixed wiring, lighting systems, control systems, etc.

for special requirements, like hospitals, nuclear power plants and power plants, can fire resistance cables be used for construction. For other individual needs, ZMS offers a Service custom wiring and convenient.

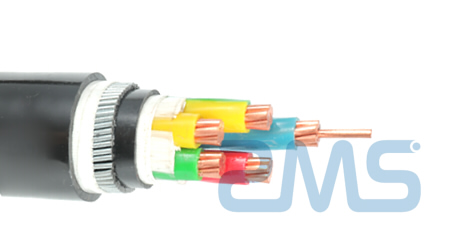

Construction and Engineering Cable Types

Low Voltage Building Cable

A variety of mechanical equipment and instrumentation systems are inseparable in the course of engineering construction. ZMS low voltage construction cables are suitable for electrical instruments, telecommunications equipment, power installations and automation devices with a rated voltage of 0.6/1KV and below.

Medium Voltage Construction Cable

Medium voltage building cables are an important part of the power supply system of buildings. ZMS medium voltage electrical cables use XLPE insulation to provide reliable power transmission over long periods of time. They also have the ability to provide continuous power to security installations in the event of a fire..

Fireproof cables can be used in the event of a fire to limit combustion to a localized area. ZMS fire-retardant construction cables comply with the IEC fire-retardant classification. They are suitable for use in tall buildings, large shopping malls, places of entertainment and other places of commercial or public activity.

Construction Fire Resistant Cable

Fire resistant cables are difficult to ignite and have the ability to stop the spread of fire. Among them, low smoke zero halogen cables (LSZH) they are environmentally friendly, non-toxic and non-corrosive. ZMS fire resistant cables can be used in hospitals, metros, nuclear power plants, power plants, minas, petrochemical plants, etc.

Rubber cables are cables with insulation and cladding rubber. Its most important feature is that it is soft and mobile. ZMS rubber construction cables are used in construction sites and ports for electrical machinery, electrical installations and all types of mobile electrical equipment.

Case study

Jordan Real Estate - Electric system 9 Buildings

ZMS Cable Company supplied the low voltage electrical cables and the control cables according to the BS standard for the power and control systems of 9 Jordan Real Estate buildings. We organize the production of 10 cable containers in 21 days and all products were on board in 3 days.

Construction Line Requirements

- Construction cable lines should be buried in pipes or laid along walls or overhead poles. It is forbidden to place it on the ground randomly.

- The depth of cable laid directly on the ground must not be less than 0,6 m. It should be evenly laid with fine sand of thickness not less than 50 mm above and below underground cables. And then be covered with a protective layer as hard as bricks.

- Rubber cables must be fixed with insulators when laying along walls or poles. It is strictly prohibited to use bare metallic thread to tie the cable. The distance between the fixing points must ensure that the rubber cable can support its own weight. The maximum arc of fall of rubber cable shall not be less than 2,5 meters from the ground.

- Cable splices must be solid and reliable. Joints wrapped in insulation must not reduce the resistance of the original insulation and must not be subjected to stress..

- On construction sites of tall buildings, temporary cables must be buried. The location of the vertical laying of the cables must take full advantage of the shafts and vertical holes of the works in progress. The fixing point will not be less than one per floor. If the cable is laid horizontally and fixed along the wall, the maximum arc of fall shall not be less than 18 m from the ground.

Selection of Temporary Construction Line Cables

During the construction of a building or engineering, technicians must determine the number of cores, the type of insulation, the type of cover, the laying method, the voltage and length of the cables. In the changing environment of construction on the site, rational choice and proper laying method of cables can effectively guarantee the service life of construction lines, reliability of power supply and safety of personnel.

Selection of the number of cable cores

The number of conductors chosen for the cable is related to the grounding of the system and the number of phases in the circuit.. Temporary feeding centers for construction sites often use low voltage power supply 220/380V three-phase with direct ground connection. Five-core cables are suitable for three-phase circuit and three-core cables for single-phase circuit.

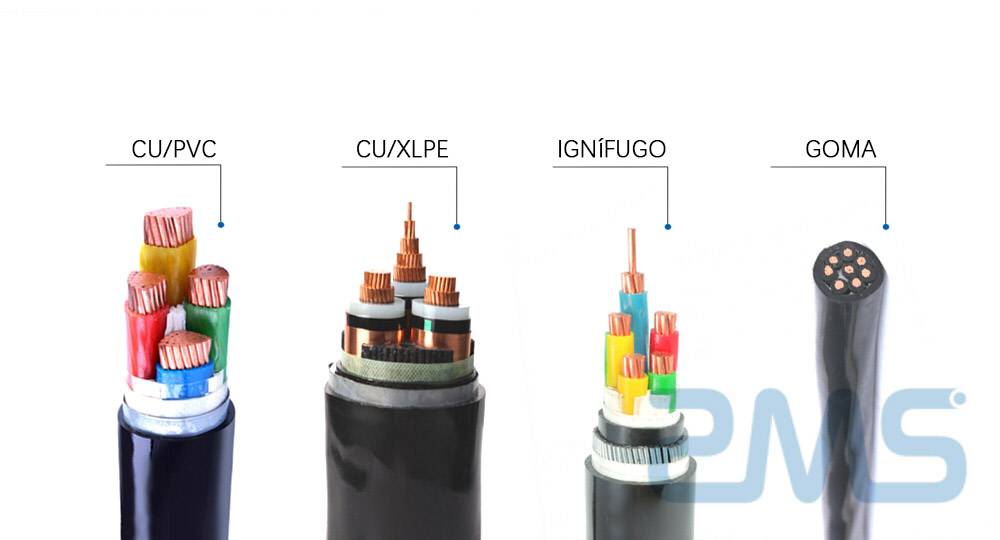

Selection of the type of cable insulation

Temporary construction cables on construction sites are often moved with the distribution box in use. The insulation of the cable directly affects its useful life. So, attention must be paid to the choice of the type of insulation when buying electric cables.

Mobile electrical equipment and other lines that are frequently bent or have high flexibility requirements should use rubber-insulated cables.. These types of cables should also be used for lines that move frequently., such as distribution box connections to electrical equipment lines.

Except in places with low temperatures below -15°C and high temperatures above 60°C and in places with fire protection requirements, low voltage cables with PVC insulation can be used. Cold-resistant rubber and XLPE insulations are available for temperatures below -15°C. Construction work is not allowed in hot places over 60°C.

Cables for temporary use on construction sites must undergo an insulation test with a megohmmeter before use.. The insulation resistance value should not be less than 0,5 MΩ.

Selection of cable placement method

The cables of the work must be buried or laid in the air, strictly prohibited along the open ground. And it should avoid the mechanical damage and corrosion of the media. Los metallic armor cables should be used for laying buried. For aerial placement, bare wires preferred.

The cables that go from the distribution boxes to the sub-distribution boxes are relatively fixed on the construction site.. Therefore, They are usually placed underground.. The route of buried cables must be marked with an orientation sign.

ZMS Worldwide Cable Distributor

ZMS cables are currently exported to various countries and regions for use in the construction of electrical installations.. At the same time, los electrical copper cables They are popular in the industry for their good quality and competitive prices..

throughout the years, ZMS company has become one of the world's leading cable providers. We not only have rich experience in cable manufacturing, but also an honest and trustworthy heart. ZMS has delivered high quality cables from China to the world. Made in China is famous all over the world.