Instrumentation Cable

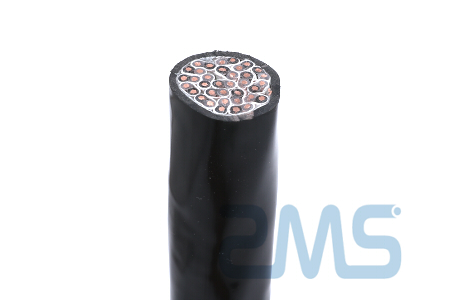

The instrumentation cable is a cable used to transmit electrical signals, usually to connect sensors, transmitters, instruments and other devices in instrumentation and control systems. It is composed of multiple fine electrical wires twisted.

The ZMS instrumentation cables have high ability of anti-interference and stability., allowing them to accurately transmit digital and analog signals. This series of products has a wide range of types, including screened cables instrumentation cables and flame retardant cables for instrumentation, among others. They can be used in areas such as industrial automation, instrument control and power systems.

ZMS Instrumentation Cable Types

BS 5308 Instrumentation Cable

- Conductor: annealed copper / Tinned copper

- Isolation: PE / XLPE / Small belt

- Apantallamiento: Aluminum Plastic Composite Tape

- External cover: PVC / LSOH

- Operating temperature: 0˚C a +50˚C

- laying temperature: -40˚C a + 70˚C

- Minimum radius of curvature: 5xOD

El BS 5308 Unarmoured instrumentation cable is mainly used in indoor applications to provide services and transmission of communication signals, data and voice in industrial processes.

driver section | MM2 | 0.5 | 0.5 | 0.75 | 1.0 | 1.5 |

conductor size | NO.XMM | 1 x 0.8 | 16 x 0.2 | 24 x 0.2 | 1 x 1.13 | 7 x 0.53 |

conductor resistance (max) | OHM/KM | 36.8 | 39.7 | 26.5 | 18.2 | 12.3 |

insulation resistance (min) | GOHM/KM | 5 | ||||

Capacitance unbalance value | PF/250M a 1KHZ | 250 | ||||

Induction/impedance between adjacent nuclei (max) | ΜH/OHM | 25 | 25 | 25 | 25 | 40 |

maximum rated voltage | V | 300/500 | ||||

Armored Instrumentation Cable

- Conductor: annealed copper / Tinned copper

- Isolation: PE / XLPE / Small belt

- Apantallamiento: Aluminum Plastic Composite Tape / copper wire/tape

- Armor: Galvanized Steel Wire/ Steel Tape

- External cover: PVC / LSOH

- Operating temperature: 0˚C a +50˚C

- laying temperature: -20˚C a +90˚C

- Minimum radius of curvature: 6xOD

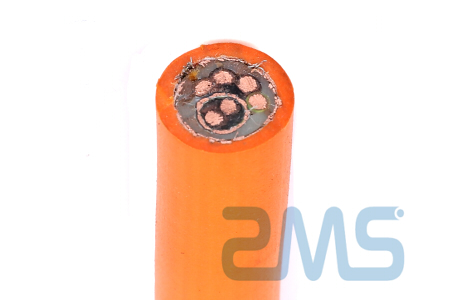

Armored instrumentation cable is mainly used in environments prone to mechanical damage. This type of cable is also commonly used in the interconnection of electrical equipment and instruments in the chemical or petrochemical industry.. The metallic armored cable can be used in outdoor installations, either laid directly on the ground or through conduits.

Flame Retardant Instrumentation Cable

- Conductor: annealed copper

- Isolation: XLPE compound

- Apantallamiento: Aluminum/polyester tape with 0.5mm2 tinned copper wire

- Armor: galvanized steel wire

- Outer covering: Thermoplastic PVC compound that meets fire performance standards (IEC 60332-1, IEC 60332-3, UL 1581, etc.)

- Work temperature: -30°C a +90°C

- installation temperature: -5°C a +50°C

- Minimum radius of curvature: 7.5xOD (no armor), 10xOD (with armor)

The flame retardant instrumentation cable not only has high resistance to interference and stable electrical performance, but also has a safety effect by preventing the spread of fire. Therefore, It is flame retardant cable type widely used in detection and control systems in industries such as power plants, mines and petrochemical industry.

driver section | MM2 | 0.5 | 0.75 | 1.0 | 1.3 | 1.5 | 2.5 |

insulation thickness | MM | 0.55 | 0.55 | 0.55 | 0.6 | 0.6 | 0.7 |

conductor resistance | OH/KM | 36.7 | 25 | 18.5 | 14.2 | 12.3 | 7.4 |

insulation resistance | MΩ/KM | 5000 | |||||

interaction capacity (max) | PF/M a 1KHZ | 115 | |||||

Induction/impedance between adjacent nuclei (max) | ΜH/OHM | 25 | 25 | 25 | 40 | 40 | 60 |

maximum rated voltage | V | 500 | |||||

Characteristics of ZMS Instrumentation Cables

Conductor Size and Options

ZMS screened instrumentation cables are available in different conductor sizes, both in copper conductor like aluminum. Copper conductor sizes include 1,0 mm2, 1,5 mm2, 2,5 mm2 y 4,0 mm2. Aluminum conductor sizes include 1,5 mm2, 2,5 mm2, 4,0 mm2 y 6,0 mm2. The most versatile are 4 AWG instrumentation cables.×18, instrumentation cables 2×18 and instrumentation cables 2×16.

Number of Conductors Options

ZMS instrumentation cables are available in different conductor count configurations. Usually, cables with less than 8 conductors usually have a size of 1,5 mm2, while multi-conductor cables with more than 8 conductors usually have a size of 1,0 mm2. For wiring in instrument cabinets, instrumentation cables are available 0,75 mm2.

Mechanical strength

In addition to the ability to conduct electricity, instrumentation cables must also have adequate mechanical resistance. Mechanical resistance determines the durability and ability of the cable to withstand stress and physical stress during installation and use.. The ZMS instrumentation armored cables have a high mechanical resistance.

Low Electric Charge

Instrumentation cables are designed to carry small electrical charges., as instrumentation signals. Therefore, ZMS instrumentation cables are typically relatively thin compared to higher capacity power cables.

Additional Advantages

In addition to the basic features mentioned above, ZMS instrumentation cables can offer other advantages, as a good resistance to electromagnetic interference (EMI), low capacitance and high precision in signal transmission.

ZMS CABLE Professional Services

And ZMS, We are proud to offer a wide range of high quality instrumentation cables to meet all your needs.. Our cables are designed with reliability in mind., performance and durability, ensuring that your instrumentation systems perform optimally at all times.

Top Quality

all our control and instrumentation cables are manufactured with the best materials and comply with the most rigorous quality standards in the industry. This ensures accurate and reliable signal transmission., resulting in accurate and consistent measurement and process control.

Wide Variety of Options

We recognize that each project is unique and requires customized solutions.. So, we offer a wide variety of instrumentation cables with different conductor sizes and conductor count configurations. Whether you need copper or aluminum cables, we have the right option.

Exceptional Mechanical Resistance

We know that instrumentation cables must not only be efficient conductors, but also resistant to stress and physical efforts. Our cables are designed to withstand the most demanding demands, ensuring long life and reliable performance in harsh industrial environments.

Protection against Electromagnetic Interference

ZMS instrumentation cables are specially designed to minimize electromagnetic interference (EMI). This means that your instrumentation signals will be protected from external interference., ensuring accurate measurements and stable signal transmission.

Exceptional Customer Service

And ZMS, we strive to provide exceptional customer service. Our team of experts is ready to help you at every step of the process., from selecting the right cable to post-sale technical support. We care about your satisfaction and make sure you receive the best possible service..

Do not compromise the quality of your instrumentation project. Trust ZMS professional cabling services to get the best results. Explore our wide range of instrumentation cables and find out how we can help you achieve your goals.. Contact us today and let us be your trusted partner for quality cables.