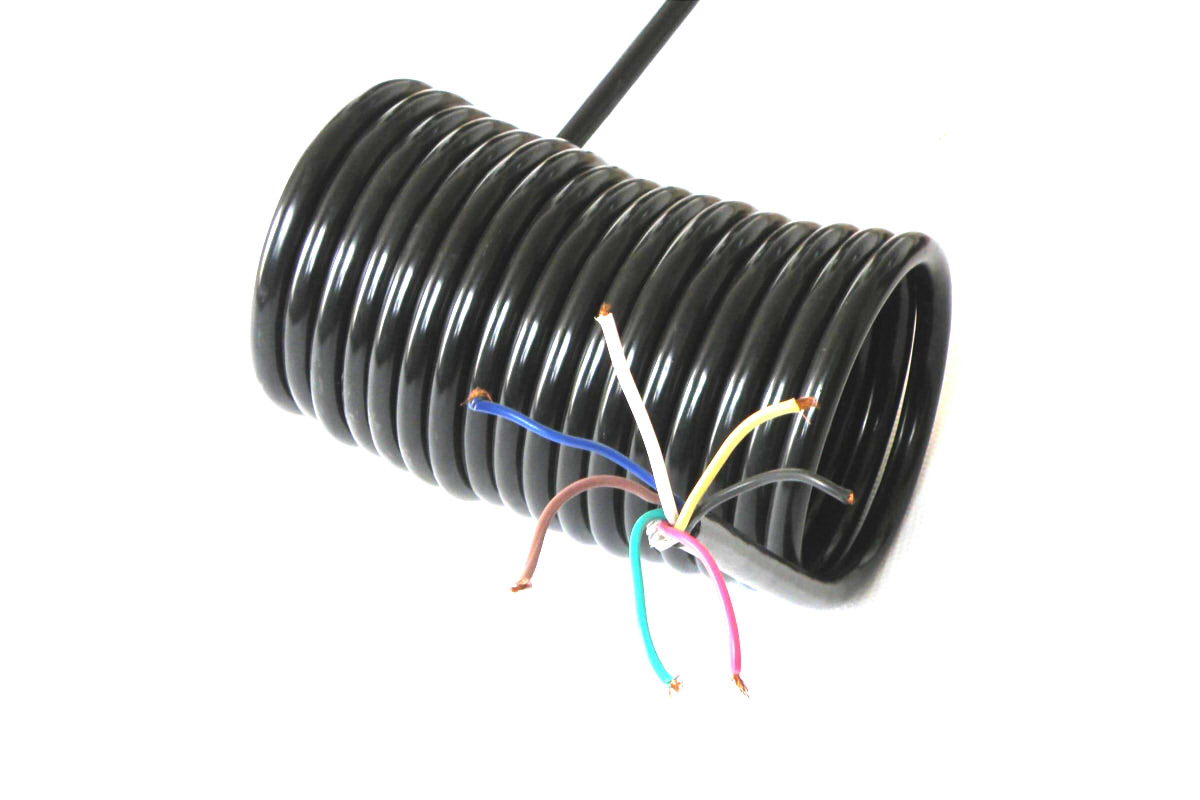

spiral cable, also known as spring cable, is a type of rope that offers a unique combination of elasticity and drag resistance. This wire can be stretched and bent as needed and then spring back to its original shape.

This is achieved by manufacturing of cables from various groups of wires insulated that are braided together and then hot rolled before cooling to maintain their spring form. This unique feature gives it several advantages that make it valuable in a wide range of industries..

Table of Contents

- Main Characteristics of Spiral Cable

- Diversified Applications

- Types of Spiral Cables

- Important Considerations When Selecting Coiled Cables

- conclusions

Main Characteristics of Spiral Cable

Good Elasticity

The coiled cable takes advantage of the spring principle and exhibits excellent stretch and recovery ability. Can be bent and stretched according to application needs.

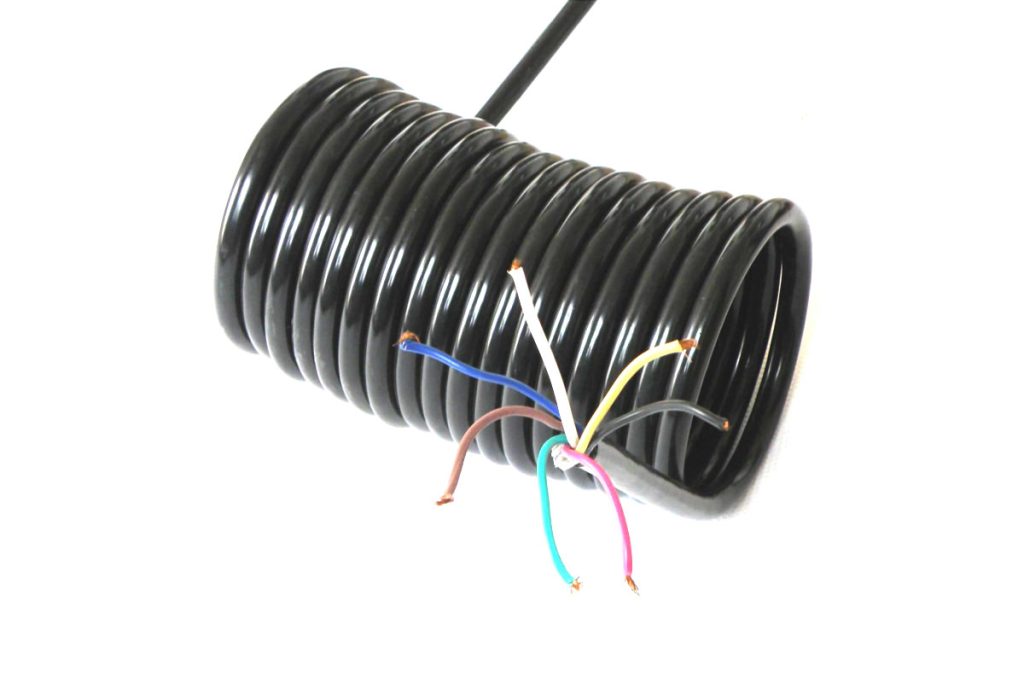

Diversified Materials

The key components of spiral cables, like the core, insulation and cover, can be manufactured from a variety of materials to suit different environments and requirements. These materials include copper, aluminum, polyolefin, polyurethane, Silicone rubber, among others.

Security

Coiled cord is less likely to become tangled and strained during use, which prevents the control cables and sensors get attacked, if it hurts or if it hurts. This reduces the risk of injury to operators due to accidents..

Wide Range of Applications

Coiled cables are widely used in mechanical equipment, electronic, mining construction, ground facilities of airports and many other fields, including automated production lines, robotic equipment, medical equipment and CCTV systems, among others.

Diversified Applications

Coiled cables are a necessity in almost all industries. Whether in communications (telephony, radio), medical technology, electric railway industry, mechanical Engineering, computing, electronic equipment, machinery, maintenance equipment, control buttons, automobiles, trailers, instrumentation or lighting industry, coiled cables find applications everywhere.

In addition to its electrical-mechanical advantages, Coiled cables are often used as excellent solutions for optical constructions. The colors of the PVC and PUR cables They can be coordinated in most cases with the color of the object. This improves its aesthetics in various applications.

It's important to put attention on, While coiled cables offer a unique combination of elasticity and drag resistance, Its manufacturing process can be more complex and expensive compared to conventional cables.

Besides, It is essential to recognize that coiled cables are not the optimal solution in all environments and applications. Its performance may be compromised in extreme situations, such as exposure to corrosive chemicals or the presence of high-voltage electrical fields. In such cases, Choosing an inappropriate coiled cable may not only result in poor performance, but also in risks to the security and integrity of the systems.

Therefore, when selecting spiral cables, It is essential to follow the standard regulations and requirements applicable to your specific industry and application. This ensures that the cables chosen are suitable for the environment in which they will be used and meet the necessary safety standards. Besides, it is recommended consult with cable and electrical experts to ensure an informed and safe choice.

Types of Spiral Cables

There are several types of spiral cables designed to adapt to different requirements and application conditions.. Next, Some of the most common types are presented:

PVC Spiral Cable

- High Economy: This type of spiral cable is affordable and suitable for low mechanical and chemical resistance applications..

- Medium Elastic Strength: Offers moderate elasticity.

- Applications: Used in light industry, computers and other applications where simple installation is required.

PUR Spiral Cable

- Very Good Elastic Strength: It has excellent elasticity.

- Excellent Mechanical and Chemical Properties: Resists the cold, Oil, adverse weather conditions, abrasion and tear.

- Applications: Ideal for machinery manufacturing, power tools and many other applications. It is the optimal solution in most cases.

PUR Spiral Cable with Shielding

- Excellent Chemical Properties: It is particularly resistant to cold, Oil, adverse weather, abrasion and tear.

- Global Spiral Shield: It can resist a variety of electromagnetic interference and is suitable for applications that require very small installation space, such as the medical industry and semiconductor manufacturing.

Neoprene Coiled Cable

- Highest Spring Force: It is the strongest spiral cable.

- Excellent Resistance to Weather and Chemicals: Resists all types of oil and chemicals, and has excellent tensile and flexural properties.

- Wide Applicability: It is widely used in construction, transportation and metallurgy equipment.

Important Considerations When Selecting Coiled Cables

When selecting coiled cables for a specific application, It is essential to take into account several key factors:

- Work temperature: Coiled cables have different working temperature ranges. Be sure to select a cable that is suitable for the temperatures present in your application environment.

- Chemical Environment: Consider chemical exposure, oils or other corrosive substances in your work environment and choose a cable that is resistant to these elements.

- Elasticity Requirements: Evaluate how much elasticity and stretchability the cable needs in your particular application.

- Specific Application: Consider the intended use of the cable, like the transmission of electrical signals, power supply or data transmission. Make sure the cable is suitable for your purpose.

- Rules and Regulations: Comply with applicable standards and regulations in your industry and geographic location when selecting spiral cables.

conclusions

Coiled cables are a versatile, highly elastic solution that finds applications in a wide variety of industries.. Your ability to stretch and recover, along with the variety of materials available, make them a valuable option for applications requiring flexibility and drag resistance such as charging cables for EV. When selecting spiral cables, Careful consideration of environmental and application factors is essential to ensure optimal performance and workplace safety. With its ability to adapt to a variety of environments and requirements, Coiled cables continue to play a crucial role in electrical and mechanical connectivity around the world.