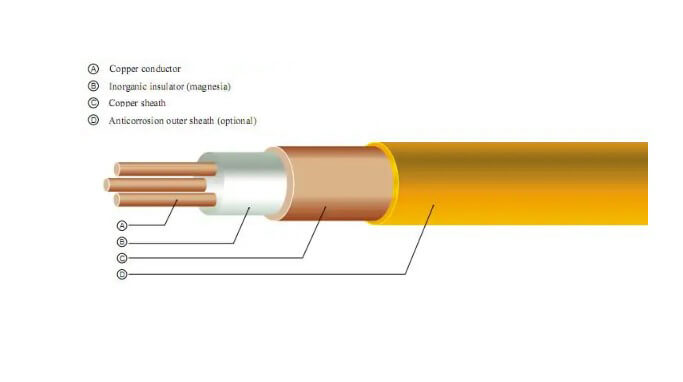

Mineral insulated heating cables use a single or multi-alloy electrical heating wire as the heat source. The magnesium oxide high-purity, high-temperature electrofused crystalline is used as a heat-conducting insulator.

Continuous stainless steel or seamless copper tubes are used as lining. This heating cable is manufactured by a special production process.

Highly corrosive locations can be covered with PE or smoke- and halogen-free outer cable sheath. Mineral insulated heating cable works on the principle that once the line is energized, heat is generated.

The amount of heat generated is determined by the voltage and resistance across the line. The current passes through the heating wire of the cable and its electrical energy can be converted into efficient heat..

Mineral insulated and plastic insulated heating cables

Components of mineral insulated heating cables are all inorganic. That is why they have a long shelf life., do not age easily and have high compressive strength.

And most models use manganese copper for the conductors.. Its resistance does not change with temperature..

Los cable conductors plastic heaters currently on the market are made of copper and are tin-plated. And its resistance varies with temperature.. Besides, Its outer coating is made of plastic and armor is steel belt.

They are bound to deteriorate over long periods of operation. It is also not possible to run these cables at high temperatures for long periods of time..

Therefore, mineral insulated heating cables have an absolute technical advantage over plastic heating cables.

Composition of mineral insulated heating cables

metal heating element: single-wire or multi-wire composition, long life of heating material

metal shield: eliminates electromagnetic fields and has no effect on people's health

Waterproof metal case: 100% protection against water leaks, high reliability

Reinforced metal sheath: increased tensile and compressive strength for use in various environments

Magnesium Oxide Insulation: high voltage and temperature resistance

Technology of mineral insulated heating cables

The heating cable pipe antifreeze system with mineral insulation uses extremely reliable electric heating technology. can heat pipes, fluids or other process equipment that needs to be insulated against freezing.

Heat lost by the fluid can be replenished and its temperature controlled to stay within allowable limits. This technology is suitable for antifreeze treatment of various piping systems and process equipment., valves and reservoirs.

For example: building water supply and drainage pipes, domestic hot water pipes, oil transmission pipes, other high viscosity liquid pipes, etc.

The mineral insulated heating cable snow and ice melting system can be used to melt snow and ice on ramps, bridges, sidewalks, catwalks, parking lots, exterior stairs and other exterior installations.

Keep pedestrians safe. The system can also be used for special pavements such as asphalt, concrete and masonry. When this system is installed, snow and ice are removed at all times. Traffic accidents are reduced and the safety of pedestrians and vehicles is increased.

Mineral insulated heating cable heating system prevents the floor from freezing. It has low maintenance costs and is safe and reliable.

It is suitable for floor heating in sports fields, all-season squares and garden lawns. It is easy and inexpensive to install and use. You can save money on frost protection and lawn maintenance.