With the strong development of sustainable energy, electrical submarine cables also find new development opportunities. Submarine cables are mainly used in the fields of offshore wind power., offshore oil and gas extraction and land-island communications and power transmission. Typical types of submarine cables include XLPE cables monoconductores and three drivers.

Development of Offshore Wind Energy

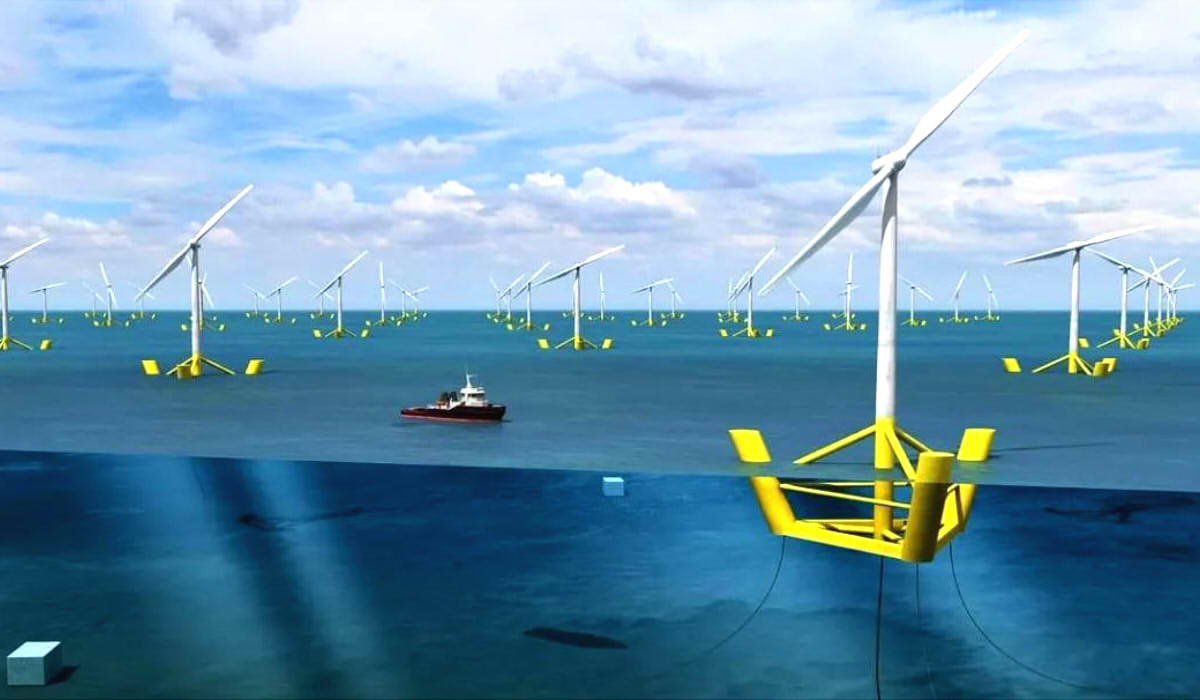

There is a clear trend towards the development of offshore wind energy in deep and distant waters. Offshore wind farm resources are becoming increasingly scarce, while far sea resources are relatively more abundant. As a result, offshore wind construction is moving further and further from the coast.

According to the US Office of Energy Efficiency and Renewable Energy., long-term, the distance to coast of global offshore wind projects will continue to increase after 2024.

Voltage Levels of Submarine Electric Cables

Submarine cables are an important part of the fabric of offshore wind energy.. There are two main types of electrical submarine cables used in offshore wind power.. One is the submarine cable within the field, which is used to connect the wind turbines to each other inside the wind farm. Another is the output submarine cable, which is used to connect wind turbines to terrestrial networks.

Currently, in-field submarine cables used are, mostly, medium voltage cables 35 kV. As the scale of wind farms and individual capacity increase, the solution of the collector of alternating current of 66 kV will be cheaper.

Outgoing submarine power cables are, mostly, ultra high voltage cables 220 kV. Today's technology can already support the production of cables of 500 three-core alternating current kV. This can reduce the number of roots of submarine cables and reduce the area occupied by the submarine corridor..

Usually, for intertidal projects, submarine cables are used 35 kV. For offshore projects (a 10-50 km from the coast) high voltage submarine cables are usually chosen 220 kV or more. And for projects in the distant sea of 80 km or more, can be considered DC flexible cables submarines for connection to the network.

Submarine Direct Current Cables

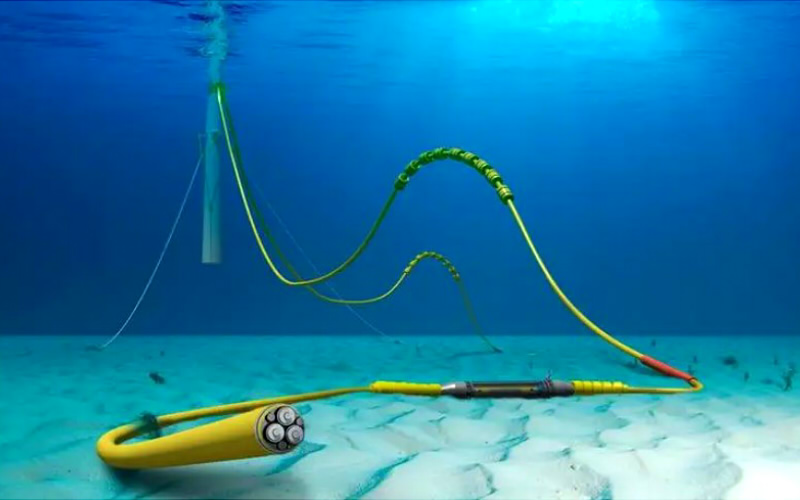

Submarine DC cables have lower line losses and are better suited for long-distance transmission. The cost of the submarine electrical transmission system includes converter stations, substations, cable lines, cable routing, shunt reactors, line losses and maintenance.

In a direct current electrical system, converter stations are needed, they are expensive. So, at shorter distances, DC systems cost more than AC systems. Nevertheless, as the distance from the coast of wind farms increases, the maintenance and wear costs of the AC system increase considerably. In this case, a direct current submarine cable transmission system will be more economical. Industry experience indicates that direct current submarine cables are necessary for distances of 70 km or more offshore.

Long-term, DC flexible solutions will become the main way to connect medium and large offshore wind farms to the grid. DC flexible transmission technology has advantages such as flexible control, the no need to voltage phase shift and the ability to provide synchronous alternating current support to wind turbines. Besides, the use of this technology can save space on offshore platforms and reduce the instability of wind power.

Investment Share of Submarine Cables in Offshore Wind Energy

Electric submarine cables occupy between the 10% and the 12% of total investment in offshore wind energy. As the scale of wind farms increases, the value share of submarine power cables shows an upward trend.

On the one hand, the larger size increases the distance between the remote wind turbines and the offshore booster station. This leads to increased investment in cables within the field. Secondly, the increase in scale pushes the capacity of the output cables to the limit and requires an increase in the number of returns to the cables. This also increases investment in outgoing submarine cables.