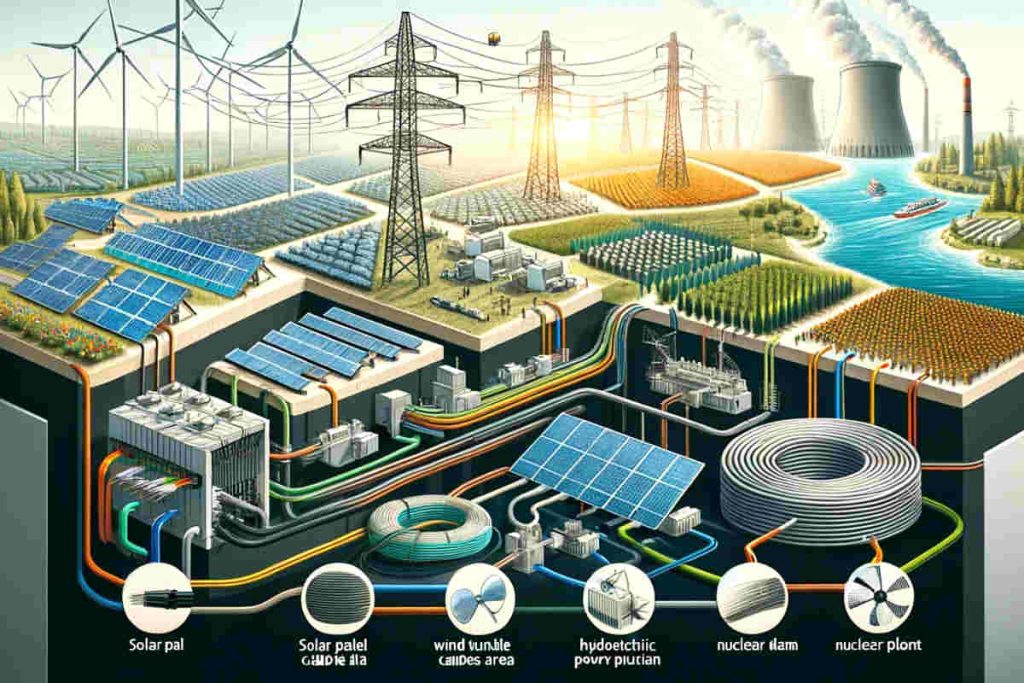

In the current era of energy transition, energy storage systems (SAE) have become a fundamental pillar to guarantee the stability of the electrical network, integrate renewable sources such as solar and wind, and optimize energy consumption in homes, industries and communities. Nevertheless, many storage projects fail to pay the necessary attention to a seemingly simple but crucial component: the cables. The cables are not merely “conductors of electricity”; are the circulatory system of the SAE, responsible for transmitting energy safely, efficient and durable. Choosing the wrong cable can lead to overheating, energy losses, system failures, fire risks and even the invalidation of guarantees. Thus, in this blog, We'll dive into how to select the right cable for your energy storage system., addressing all key factors, applicable regulations and practical recommendations adapted to different scenarios. Keep reading to avoid costly mistakes and maximize the performance of your SAE!

Why cables are essential to the performance and safety of energy storage systems

Before going into the details of the selection, It is essential to understand why cables are an irreplaceable component in energy storage systems. Unlike cables used in traditional electrical networks, SAE cables must meet specific operating conditions: variable currents (especially in systems connected to renewables), frequent charge and discharge cycles, and sometimes hostile environments (extreme temperatures, humidity, exposure to chemicals or solar radiation).

First, safety. An unsuitable cable can overheat due to excess current, which causes insulation degradation, the risk of short circuit and, in the worst case, fires. According to data from the International Electrical Safety Association (IEC), more than 30% of failures in energy storage systems are due to problems related to cables and connectors.

Second, energy performance. Cables with high electrical resistance cause energy losses in the form of heat, which reduces the efficiency of the SAE. In a large scale industrial system, These losses can translate into thousands of euros per year. For example, a copper wire with insufficient cross section in an SAE of 1 MWh can generate losses of 5-8%, which means a significant reduction in usable energy.

Third, long-term durability and cost. Low quality cables require frequent replacement, which increases maintenance costs and system downtime. On the contrary, a suitable cable, selected according to the specific needs of the SAE, can have a useful life of 15-20 years, aligned with the life of the main storage components (such as batteries or inverters).

In summary, the cables are the “structural bone” of the SAE: Its correct selection is not an additional expense, but an investment that guarantees security, long-term efficiency and profitability.

Key factors for selecting cables for energy storage systems: Step by step guide

Cable selection for SAE is not a generic process; depends on a combination of technical factors, operational and environmental. Next, We analyze each of them in detail, with practical examples for different types of systems (residential, commercial and industrial).

1. Current capacity (Ampacity): The fundamental factor to avoid overheating

Ampacity refers to the maximum amount of current that a cable can safely carry without exceeding the temperature limits established by regulations.. This factor is the most critical, since the excess current causes insulation degradation and the failures mentioned above.

To calculate the necessary ampacity, you must take into account two key SAE values: the system's rated current and peak current. The rated current is the current that flows during normal operation, while peak current occurs in fast charge/discharge situations (for example, during a blackout or peak consumption). Usually, The cable must support at least 125% of the rated current (according to NEC regulations 480 for battery systems) to cover peak situations.

Practical example: A residential system 5 kWh with inverter 3 kW (rated current = 3000 W / 230 V = 13 A) requires a cable with a minimum ampacity of 13 A x 1,25 = 16,25 A. In this case, one AWG copper wire 12 (section 3,31 mm²) is appropriate, since its ampacity is 20 In closed environments.

another example: A system of 100 MWh with rated current 500 A. The minimum required ampacity is 500 A x 1,25 = 625 A. Here, a section copper cable is recommended 300 mm² (ampacity of 630 A) or an aluminum cable 400 mm² (similar ampacity, but with lower cost).

It is also important to consider the clustering effect: if several cables are installed together in a channel or tube, heat dissipation is reduced, so it is necessary to increase the cross section of the cable (generally a 20-30% further) to maintain ampacity. For example, three AWG wires 10 (ampacity 30 A) installed together require replacement with AWG wires 8 (ampacity 40 A) to avoid overheating.

2. Nominal voltage: Adapt to the type of system (CC o CA) and its voltage

Energy storage systems can operate on direct current (CC) or alternating current (CA), and the cable must be compatible with the rated voltage of the system to ensure insulation integrity and prevent current leakage.

For DC systems (the most common in battery storage, such as Li-ion or lead-acid), The cable must have a DC voltage rating higher than the maximum voltage of the battery bank. For example, a Li-ion battery bank 48 V (maximum charging voltage 54 V) requires a cable with a rating of 600 In CC, since it is the most common standard and offers a safety margin.

For AC systems (generally connected to the electrical grid or inverters), The cable must comply with the AC voltage rating of the country. In Europe, the standard is 400 V (three phase voltage) o 230 V (single phase), so the cables must have a minimum rating of 600/1000 V CA.

A common mistake is using AC cables for DC systems: although the nominal voltage may be similar, AC cable insulation is not designed to withstand the constant polarity of DC, which can lead to material degradation over time. On the contrary, DC cables are suitable for AC in some cases, but its cost is generally higher, so it is not an economical solution.

3. Material conductor: Copper vs.. aluminum, advantages and disadvantages

The two most used materials for SAE cable conductors are copper and aluminum.. Each one has features that make it suitable for different scenarios., and the choice depends on factors such as cost, weight, ampacity and ease of installation.

Copper: It is the ideal material for SAE cables due to its low electrical resistance (1,72 x 10⁻⁸ Ω·m), high ductility (easy to fold and connect) and corrosion resistance. Its main advantages are:

- Lower energy losses compared to aluminum.

- Higher ampacity per unit cross section (a copper wire 10 mm² has the same ampacity as aluminum 16 mm²).

- Reduced risk of oxidation in connections, reducing additional resistance problems.

Its main disadvantage is the cost: copper is between 3-4 times more expensive than aluminum, which makes it less competitive in large scale systems.

Aluminum: It is an economical alternative, especially for industrial or commercial projects with long wiring distances. Its characteristics are:

- Reduced cost (about 0,8 €/kg vs. 3,5 €/kg of copper).

- Lower weight (2,7 g/cm³ vs. 8,96 g/cm³ of copper), making it easier to install at heights or long distances.

Nevertheless, has disadvantages that require attention:

- Greater electrical resistance (2,83 x 10⁻⁸ Ω·m), so you need larger cross sections to match the ampacity of copper.

- Greater tendency to oxidation: aluminum oxide is electrically resistant, so the connections must be treated with antioxidant compounds and use specific terminals (like copper-clad ones).

- Lower ductility: is more likely to break with repeated bending, which limits its use in systems with complex installations.

Recommendations: For residential or small commercial systems (until 100 kWh), Copper is the best option for its reliability and low maintenance. For industrial systems (more of 1 MWh) or long distances (more of 50 m), aluminum can be an economical alternative, provided that suitable connections are used and the cross section is increased.

4. Isolation: Protection against the environment and electrical risks

Insulation is the outer layer of the cable that separates the conductor from the environment and prevents current leakage., short circuits and accidental contacts. Your choice depends on the installation environment (interior, exterior, wet, corrosive) and SAE operating temperatures.

The most common insulation materials are:

- PVC (Polyvinyl chloride): It is the most economical material and is used in dry interior installations.. It has a maximum operating temperature of 70-90 °C and is impact resistant, but not suitable for humid environments, outdoors or exposed to solar radiation (degrades over time). Ideal for residential systems installed in garages or electrical panels.

- XLPE (Cross-linked polyethylene): It is the standard for energy storage systems, thanks to its high temperature resistance (until 90-125 °C), impermeability and resistance to corrosion and UV radiation. It is suitable for outdoor installations, wet (such as basements or coastal areas) and systems with high operating temperatures (such as Li-ion batteries that generate heat during charging). Its only drawback is the higher cost than PVC., but its durability makes up for it.

- EPR (Ethylene propylene elastomer): It is a flexible material and resistant to high temperatures. (until 150 °C), ideal for mobile storage systems (such as those used in electric vehicles or temporary projects) or installations where the cable must be bent frequently. It is also chemical resistant, so it is used in industries with exposure to solvents or oils.

- Silicone: Used in systems with extreme temperatures (until 200 °C), such as SAEs connected to concentrated solar energy generators or industrial processes with intense heat. It is very expensive, so its use is limited to specific applications.

In addition to insulation material, It is important to consider the shielding layer in environments with electromagnetic interference (EMI). shielded cables (with copper or aluminum mesh) prevent the SAE from being affected by nearby electronic equipment (such as motors or communications) and vice versa. This is crucial in storage systems connected to smart grids or monitoring systems..

5. Installation environment: Adapt to extreme conditions

The environment where the cable is installed largely determines its selection, since factors such as temperature, humidity, solar radiation, Corrosion and exposure to animals or impacts can affect its performance and lifespan.. Next, recommendations for common scenarios:

- Indoor dry installations (electrical panels, garages): Cables with PVC or XLPE insulation, no need for shielding. Prioritize ampacity and ease of installation.

- Outdoor facilities (grounds, roofs with solar panels): UV Resistant XLPE Insulated Cables, waterproof and with a layer of protection against rodents (como nylon braid). If the installation is in cold areas (under the -20 °C), choose cables with flexible insulation (as EPR) to prevent them from becoming hard and breaking.

- Humid or corrosive environments (Coast zones, floodable basements): Cables with XLPE or EPR insulation, shielded with copper mesh and exterior coating resistant to salinity or chemicals. It is also advisable to use cables with tinned copper conductor (tin coated) to increase corrosion resistance.

- Industrial environments (factories, treatment plants): Cables with chemical resistant insulation (EPR about silicone), shielded for EMI and with anti-impact coating. If there is exposure to high temperatures, choose materials with maximum operating temperature higher than 125 °C.

- Underground facilities: Polyethylene sheathed cables (PE) resistant to pressure and soil corrosion. It is necessary to protect them with PVC or steel pipes to avoid damage from excavations or ground pressure..

6. Regulations and standards: Compliance to ensure security and reliability

Compliance with regulations and standards is mandatory for any energy storage system project, as it ensures that the cables are secure and compatible with the other components of the system. The most important standards to consider are:

- IEC (International Electrotechnical Committee): IEC standards 60228 (cable conductors) y IEC 60502 (cables for electrical installations) establish requirements for the quality of drivers, isolation and ampacity. For battery systems, to the IEC standard 62133 es crucial, since it regulates the safety of components related to stored energy.

- NEC (US National Electrical Code): It is the reference standard in Latin America and the US. The section 480 of the NEC focuses specifically on energy storage systems, establishing requirements for cable ampacity (minimum 125% of the rated current), connections and short circuit protection.

- A (Spanish Standards): In Spain, UNE regulations 211000 (electrical installations in buildings) y A IN 50525 (cables for renewable energy systems) are applicable. It is also necessary to comply with the Royal Decree 842/2021, that regulates the integration of storage systems in the electrical grid.

- UL (Underwriters Laboratories): UL Certifications (as UL 44) They guarantee that the cables have passed fire safety tests, overheating and short circuits. This certification is especially important for commercial projects, since many insurers require compliance.

Failure to comply with these regulations can have serious consequences: from the invalidation of the system guarantee to economic sanctions or risks to people's safety. Thus, It is always advisable to work with cable suppliers that have the corresponding certifications and consult an electrical engineer specialized in storage systems.

Common Myths When Selecting Cables for Storage Systems: What to avoid?

Despite the importance of cable selection, There are many myths and common errors that can lead to incorrect decisions.. Next, we demystify the most frequent:

Mito 1: “The thicker the cable, better”

Although insufficient cross section is a problem, an excessively thick cable not only increases the cost, but also makes installation difficult (is less flexible) and takes up more space in electrical panels or channels. The key is to select the cable based on the calculated ampacity, without unnecessarily oversizing. For example, a residential system 5 kWh does not need a power cord 16 mm²; un AWG 12 (3,31 mm²) It is more than enough and much cheaper.

Mito 2: “AC and DC cables are interchangeable”

As we mentioned before, AC and DC cables have different types of insulation. AC insulation is designed to resist alternating polarity, while the DC one is more resistant to constant polarity. Using AC cable in a DC system can lead to insulation degradation and current leakage, while a DC cable in AC is possible, but its cost is higher without additional benefits.

Mito 3: “Aluminum is always an economical alternative to avoid”

Aluminum has a bad reputation for oxidation problems in connections, but this is a myth if proper terminals are used and good installation practices are followed. In large scale systems (as renewable energy storage plants), aluminum can reduce wiring costs by 40-50% compared to copper, without compromising safety if the cross section is increased and antioxidant compounds are used.

Mito 4: “Regulations are just a formality”

The regulations are not arbitrary; are based on years of research and experience in electrical system failures. Complying with them ensures that the cable is compatible with the other components (investors, batteries, switches) and that resists the operating conditions of the SAE. For example, the NEC standard 480 requires a safety margin of 125% in ampacity to avoid overheating during current spikes: Skipping this requirement can lead to system failure in critical situations (like a blackout).

Mito 5: “All cable providers are the same”

It isn't true. Many suppliers offer low-quality cables with recycled copper conductors (with greater resistance) or inferior material insulation. These cables can meet short-term nominal requirements, but its useful life is drastically reduced (from 20 a 5 years). To avoid this, choose suppliers with IEC certifications, UL o A, and order samples of the cable to verify the quality of the conductor and insulation.

Practical examples of cable selection for different types of storage systems

To consolidate the previous concepts, We present three practical cases of cable selection, adapted to the most common types of systems: residential, commercial and industrial.

Case 1: residential system 10 kWh with Li-ion batteries

System Features: Li-ion battery bank 48 V (maximum voltage 54 V), inverter 5 kW (rated current = 5000 W / 230 V = 21,7 A), interior installation in garage (dry environment, temperature between 15-30 °C).

Calculations: Minimum ampacity = 21,7 A x 1,25 = 27,1 A. Rated voltage = 54 In CC.

Cable recommendation: AWG copper conductor 10 (section 5,26 mm²), XLPE insulation (resistant to temperatures up to 90 °C), voltage rating 600 In CC. UL Certification 44 and NEC compliance 480.

Additional considerations: Install the cable in PVC channels to protect it from impacts, and use copper terminals to avoid oxidation. The length of the cable between batteries and converter must be less than 10 m to minimize energy losses.

Case 2: trading system 100 kWh for a shopping center

System Features: Vanadium Flow Battery Bank 400 V (CA), inverter 75 kW (three-phase rated current = 75000 W / (√3 x 400 V) = 108,25 A), exterior roof installation (UV exposure, temperature between 0-40 °C), distance between batteries and inverter 30 m.

Calculations: Minimum ampacity = 108,25 A x 1,25 = 135,3 A. Grouping effect (3 three phase cables) = increase the ampacity by a 25% → 135,3 A x 1,25 = 169,1 A. Allowable energy losses (maximum 3%) → minimum cross section = (ρ x L x I) / (ΔV x S), where ρ = copper resistivity (1,72 x 10⁻⁸ Ω·m), L = 30 m, I = 108,25 A, ΔV = 400 V x 0,03 = 12 V. Result: minimum section 16 mm².

Cable recommendation: copper conductor 25 mm² (ampacity 180 A), UV resistant XLPE insulation, copper mesh shielding (for EMI), voltage rating 600/1000 V CA. IEC Certification 60502 and compliance with UNE EN 50525.

Additional considerations: Install the cable in stainless steel tubes to protect it from the elements, and use connections with antioxidant compounds. Perform resistance measurements after installation to verify that there are no problems at the joints.

Case 3: industrial system 500 MWh for a solar plant

System Features: Li-ion battery bank 1500 V (CC), inverter 300 MW (rated current = 300.000.000 W / 1500 V = 200.000 A), underground and outdoor installation (distance between batteries and inverter 100 m), corrosive environment (near a coastal area).

Calculations: Minimum ampacity = 200.000 A x 1,25 = 250.000 A. Due to high current, It is recommended to use cables in parallel (10 cables 300 mm² each, cable ampacity 630 A → 10 x 630 A = 6300 A? No, correction: for very high currents, Large section copper conductors or bar cables are used. In this case, copper cables are chosen 1000 mm² (ampacity 1200 A) in parallel: 250.000 A / 1200 A ≈ 208 cables per phase. But this is impractical, Therefore, it is recommended to use copper bar cables of 100 x 10 mm (ampacity 2500 A) in parallel: 250.000 A / 2500 A = 100 bars per phase.

Cable recommendation: copper bars 100 x 10 mm (conductor), corrosion resistant EPR insulation, polyethylene coating (PE) for underground installation, voltage rating 2000 In CC. IEC Certification 62133 and NEC compliance 480.

Additional considerations: Install bars in salinity-resistant steel ducts, perform dielectric stress tests before commissioning the system, and monitor the temperature of the connections with integrated temperature sensors.

Final Tips for Selecting Cables and Maximizing the Performance of your SAE

Selecting cables for energy storage systems is a technical process that requires attention to detail, but with the right knowledge, you can avoid costly mistakes and ensure the safety and efficiency of your project. Next, some final tips to apply in practice:

- Perform a detailed analysis of the system needs: Before buying cables, defines the nominal and peak current, the voltage, the installation environment and distances between components. This will help you calculate the necessary ampacity and cross section.

- Consult a specialized electrical engineer: If the system is large scale (more of 100 kWh) or the environment is complex (corrosive, extreme temperatures), It is advisable to hire a professional with experience in storage systems. They will be able to verify your calculations and recommend the most appropriate materials..

- Choose reliable suppliers with certifications: Don't be tempted by cheap cables without certifications. Suppliers with IEC certifications, UL or UNE guarantee that their products meet safety and quality standards.

- Prioritize correct installation: Even the best cable degrades if installed incorrectly. Use appropriate terminals, avoid excessive bending, protects the cable from impacts and corrosion, and perform resistance and tension tests after installation.

- Perform periodic maintenance: Inspect cables and connections every 6-12 months to detect signs of degradation (insulation coloring, heat at the joints, oxidation). Replace any component that shows signs of deterioration to avoid failure.

- Consider future system scaling: If you plan to expand your SAE in the future, select cables with a higher ampacity than currently needed. This will avoid having to replace all the wiring when you increase the capacity of the system.

Conclusion: The cables, a key investment for the success of your storage system

Energy storage systems are a strategic investment to adapt to the energy transition and guarantee energy security. Nevertheless, Your success depends on seemingly small but crucial components, like the cables. Choosing the right cable not only prevents security risks (fires, short circuits), but also maximizes energy efficiency, reduces maintenance costs and extends system life.

In this blog, We have analyzed the key factors for cable selection: ampacity, rated voltage, material conductor, isolation, installation environment and regulations. We have also demystified misconceptions and presented practical examples for different types of systems. The key is to approach the process technically, based on accurate calculations and in compliance with applicable standards.

If you have questions about cable selection for your energy storage project, Feel free to leave a comment below or contact a specialized professional. Remember: a well-selected cable is the basis of a secure storage system, efficient and profitable.

What experience have you had in selecting cables for storage systems? Share it in the comments, We are eager to know your opinion!