Copper clad aluminum cable is an innovative solution that seeks to balance the cost and performance of cables in a context of scarce copper resources.. This type of cable is characterized by having a main aluminum conductor covered by a layer of copper on the outside.. The introduction of this technology has made it possible to take advantage of the copper conductor, as its excellent electrical performance, while reducing the cost and weight associated with using aluminum as the primary material.

The aluminum cable manufacturing Copper clad is achieved by cladding welding, where a high quality copper tape is coated around an aluminum core or steel wire. This process creates a solid metallurgical bond between the copper and the core, making both materials behave like a single metal thread. This allows the wire to be stretched and annealed without compromising its integrity., keeping the relative volume of the copper layer constant.

Copper clad aluminum cable finds a wide range of applications in various fields. Depending on your specific use, cable can be classified into two main categories: copper-clad aluminum cables for signals or communications, and copper-clad aluminum cables for power supply.

Table of Contents

- Characteristics of Copper Clad Aluminum Cable

- Identification Methods of Copper Clad Aluminum Cables

- Aspects to Take into account when Buying Copper Coated Aluminum Cables

Characteristics of Copper Clad Aluminum Cable

Balanced electrical performance

Although the electrical conductivity of aluminum is lower than that of copper, copper-clad aluminum cable makes up for this difference in some applications. If used to supply electricity, copper clad aluminum conductor will cause additional power consumption and further voltage reduction. Nevertheless, at high frequencies, where the skin effect is relevant, The transmission performance of the cable is similar to that of pure copper. This is because the copper layer on the outer surface of the cable allows current to flow primarily in the copper, minimizing resistance attenuation. At frequencies up to 5 MHz, both conductors show comparable AC resistance, which guarantees efficient signal transmission and good communication quality.

Lightness and flexibility

Copper-clad aluminum cable is considerably lighter than pure copper wire. This feature makes it easy to transport, handling and installation, resulting in greater efficiency and convenience during the construction of electrical networks or the installation of communication systems. Besides, Its greater flexibility compared to pure copper allows for easy straightening and lower return loss during the manufacturing process.

Adequate mechanical resistance

Although the pure copper conductor has greater resistance and elongation, Copper-clad aluminum conductor offers sufficient mechanical strength for most practical applications. Its design guarantees the structural integrity and durability of the cable, while reducing your overall weight. This results in easier installation and a reduction in the physical efforts required..

Economic efficiency

Even though copper-clad aluminum conductor has a slightly higher price than pure copper of the same weight, Its length is approximately 2.5 times greater. This means that a longer cable length can be obtained using the same amount of material.. Consequently, the cable price It is calculated according to its length, resulting in a lower total cost per unit length. Besides, due to its lower weight, Copper-clad aluminum cable reduces transportation and installation costs, which contributes to greater savings in terms of operating costs.

corrosion resistance

Copper coated aluminum offers good corrosion resistance due to its copper coating. The copper coating completely protects the aluminum from being in direct contact with water, humidity or air, thus avoiding corrosion of aluminum. By having a concentric copper layer on its surface, copper-clad aluminum cable acquires properties similar to those of pure copper in terms of corrosion resistance. This is especially beneficial in corrosive environments, such as coastal areas or chemical industries, where the presence of corrosive substances can damage conventional copper cables. When choosing copper clad aluminum cable, The risk of corrosion is reduced and greater durability and useful life of the cable is ensured.

Weldability

Copper-clad aluminum cable features good solderability, similar to that of pure copper cable. The copper layer on the outer surface of the conductor allows the cable to be easily soldered using conventional soldering techniques. This facilitates its production and allows a safe and reliable connection of the cable terminals.. The solderability of copper-clad aluminum cable is particularly important in applications where a solid, low-resistance connection is required., such as in electrical or communication systems. By providing reliable weldability, This type of cable ensures a more efficient installation and reduces connectivity problems that may arise with other materials.

Identification Methods of Copper Clad Aluminum Cables

Copper clad aluminum cables may appear similar to other types of cables at first glance., such as magnesium and aluminum clad aluminum cables, and copper-clad steel cables. Nevertheless, There are several methods that can be used to accurately identify copper clad aluminum cables.:

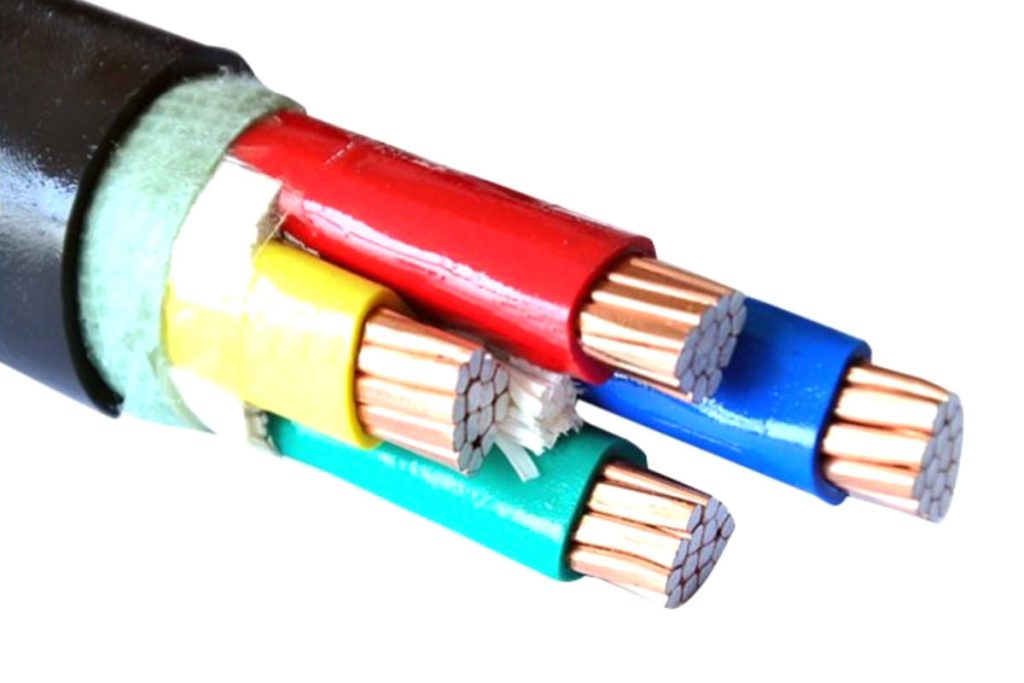

Cross section observation

Thicker cables that use copper clad aluminum can be easily identified. These cables are usually flexible and composed of several fine threads. By cutting the cross section of a wire and observing if it appears white (the color of aluminum), can determine if it is a copper clad aluminum cable.

Burn test

A simple test consists of using a lighter and observing the combustion phenomenon and the subsequent results.. Copper clad aluminum wires and magnesium clad aluminum wires melt in a straight line and are not easy to burn. After combustion, the driver color will be gray or even black, because the melting point of aluminum is lower than that of copper. Nevertheless, there is a key difference: Copper-clad aluminum cables break easily when twisted in your fingers and are more brittle, breaking into multiple sections. Secondly, If a bare copper wire is burned without oxygen and a ball of molten metal is formed, then it's copper. Copper wires can also have different thicknesses and results after burning, with the fine threads melting and the thick threads remaining intact.

Scrape with a tool

When scraping a tinned copper wire, a yellow color will be revealed, indicating that it is copper. If a bare copper wire without oxygen is scraped, will keep its original color, confirming again that it is copper. Nevertheless, Copper clad aluminum wires and magnesium clad aluminum wires will show white spots when scratched. The same effect can also be obtained by rubbing the thread on a cement surface. In the case of copper-clad steel cables, They can be identified using a magnet or by the same scraping technique.

Aspects to Take into account when Buying Copper Coated Aluminum Cables

To Avoid Buying Poor Quality Copper Clad Aluminum Cables, It is important to take certain precautions. First, It is recommended to verify the qualifications of the electrical cable manufacturer, as well as review certification and quality testing reports.

In general, Copper clad aluminum cables are composed of soft copper wire, which makes it easier to identify. A simple method is to burn the end of the wire using a lighter flame.. Because the melting point of aluminum is lower than that of copper, If it is a copper clad aluminum cable, the burned part will quickly turn into ashes, without a trace. Instead, yes it is pure copper, the wire will shrink quickly after burning, leaving a small ball at the end during the shrinking process.