In the world of electric power transmission, cables play a crucial role in carrying electricity from its generation to the points of consumption. Nevertheless, not all cables are the same, and one of the fundamental aspects that distinguishes them is their ability to withstand different levels of tension. In this article, we will explore the differences between high and low voltage cables, analyzing its characteristics, applications and technical considerations.

Understanding these disparities will help us better understand how electrical power is transmitted and how cables adapt to the specific needs of each context..

Table of Contents

- Differences between high and low voltage cables

- How to distinguish between high voltage and low voltage cables

- Can high voltage cables be used as low voltage cables??

Differences between high and low voltage cables

High and low voltage cables belong to a category of electrical power cables and are mainly used in power transmission networks. There are big differences between high and low voltage cables, which are mainly reflected in the following aspects.

voltage differences

Usually, cables with voltages below 1 kV (including 1 kV) are considered low voltage cables, while those with more than 1 kV are considered medium and high voltage cables. In our daily life, It is common to find cables with voltage levels of 0.6 kV y 10 kV, for example.

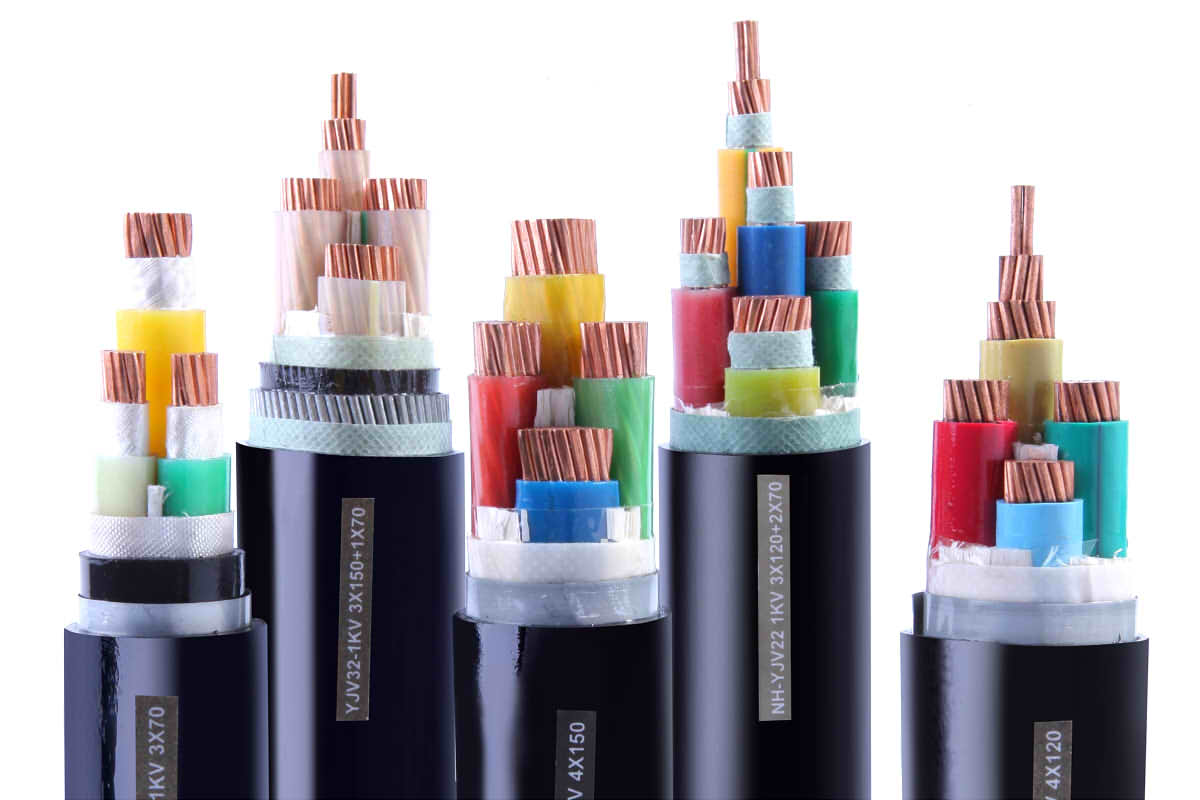

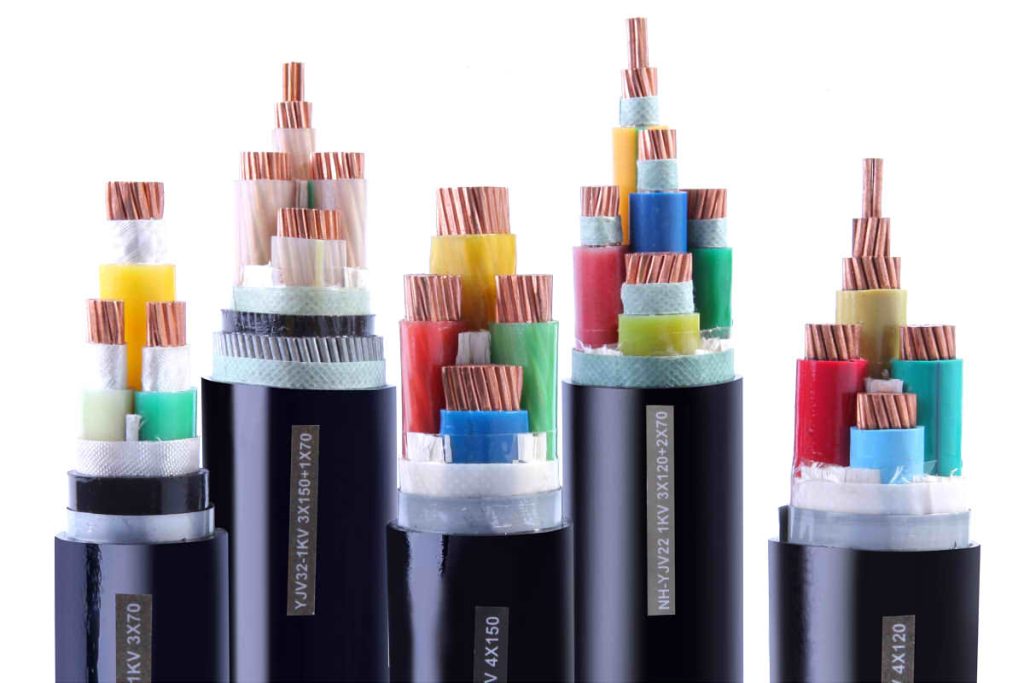

structure differences

The structure of low-voltage cables differs from high-voltage cables in aspects such as the shielding layer of the conductor, the insulation layer and the metallic cover. These differences are due to different insulation capacity requirements depending on the voltage level.. For example, the insulation capacity of a low voltage cable 0.6 kV is much weaker than one of 10 kV, which hinders its resistance to the passage of current through the air or through the insulation.

conductor shielding layer

Since the conductor is made up of multiple strands of rigid wire, its surface presents empty spaces that can cause non-uniform electric fields and partial discharges. Therefore, a conductive non-metallic material is used to fill these gaps to ensure a tight fit with the insulation layer, thus achieving a uniform electric field and prolonging the life of the cable.

insulation layer

The distance between bare conductors on a wire 10 kV is from 125 mm, while on the cable it is very small. Therefore, a high quality cross-linked polyethylene material is required to manufacture the cable insulation. Usually, the thickness of the insulation layer in models of 8.7/15 kV should not be less than 4.5 mm.

Insulation shielding layer

Due to the presence of gaps between the insulation layer and the outer covering, a conductive semiconductor layer is added outside the insulation layer to obtain a uniform electric field and prevent partial discharges.

Protective metal shield layer

In order to ensure a reliable ground connection of the semiconductor layer, an outer protective metal layer is added. When the metallic layer of protection works correctly, discharges the capacitive current distributed between the cable and other conductors to ground, while also acting as a barrier against electromagnetic interference to prevent interference to other equipment.

Steel Tape Armor Layer

The armor layer is used to increase the mechanical resistance of the cable and improve its ability to resist corrosion.. These steel armored cables are specially designed for areas prone to mechanical damage or corrosion.

Differences in use

- High voltage cables must be precisely fabricated at the ends before use., following strict manufacturing processes. Secondly, it is not mandatory to manufacture the ends of the low voltage cables.

- The installation of LV cables is more flexible and does not require a specific route. Nevertheless, HV cables must have their installation route determined in advance.

- During the installation of low voltage cables, no need to bury them deep with sand and bricks as in the case of high voltage cables. In general, are installed at a shallower depth, making them more prone to damage from external forces and possible failure.

- Low voltage cables tend to have shorter lengths, ranging from several tens of meters to several hundred meters. Meanwhile, high voltage cables often require lengths ranging from several hundred meters to several kilometers.

- Low voltage cables have lower insulation resistance requirements. Besides, troubleshooting and splicing processes are simpler.

- Most low voltage cable failure points have visible burn damage. This makes it easy to locate faults and troubleshoot cables..

- Low voltage cables support more significant load changes and are often unbalanced, which can generate heating. As a result, cable faults are more common.

How to distinguish between high voltage and low voltage cables

Isolation

In general, the insulation of low voltage cables is relatively thin, generally between 1 Y 3 mm. In the case of medium voltage cables of 10 kV a 35 kV, the thickness of the insulation is usually 5 a 8 mm. For high voltage cables greater than 35 kV, the thickness of the insulation is usually greater than 10 mm.

Marking on the outer cover

In general, electrical wires have relevant information, like the model, rating and voltage, printed on its outer cover. For example, you can find brands like YJV-1KV-4×150 o YJV-10KV-4×150. This information provides details about the cable model and specifications.

Fabrication process

Low voltage cables can be made using chlorinated polyvinyl (PVC) the cross-linked polyethylene (XLPE) as insulation. Secondly, medium and high voltage cables generally use crosslinked plastic insulation. for wires 6 kV a 35 kV, a layer of high density cross-linked polyethylene can be used in a triple extrusion process.

Can high voltage cables be used as low voltage cables??

HV cables can be used as low voltage cables, as long as your safe current capacity meet the usage requirements. This is because cable selection is primarily based on two requirements. First, the nominal voltage of the cable must be greater than or equal to the actual voltage of use. Second, the safe current capacity of the cable must be greater than or equal to the actual current of use.

Nevertheless, using high voltage cables as low voltage cables is not ideal. This is because the design and manufacture of high voltage and low voltage cables are different.. The insulation layer and outer sheath of high-voltage cables are thicker and have a higher voltage resistance than low-voltage cables.. If high voltage cables are used in low voltage circuits, can result in cables that are too heavy, making it difficult to install and maintain.

Besides, high voltage cables are considerably more expensive than low voltage cables. Using HV cables in situations of LV cables would result in wasted materials and higher costs.. Besides, the electrical parameters of high voltage cables differ from low voltage cables, which could represent a potential threat to the stability and safety of the circuit.