Electrical professionals must select the appropriate cable based on the power of the load, the distance from the supply and the loss due to voltage drop of the line, the temperature and humidity of the environment. ZMS brings you two examples of errors in the selection of electrical cables, from which we hope you learn from this.

Case 1: Improper Cable Selection Due to Load Current

A factory electrician had selected cables for a production facility with the following specific requirements:

- Three-phase supply of 380 V

- 22KW charging motor power

- Feeding distance of about 130 m

- permissible voltage drop of 5% On the line

- power factor 0,85

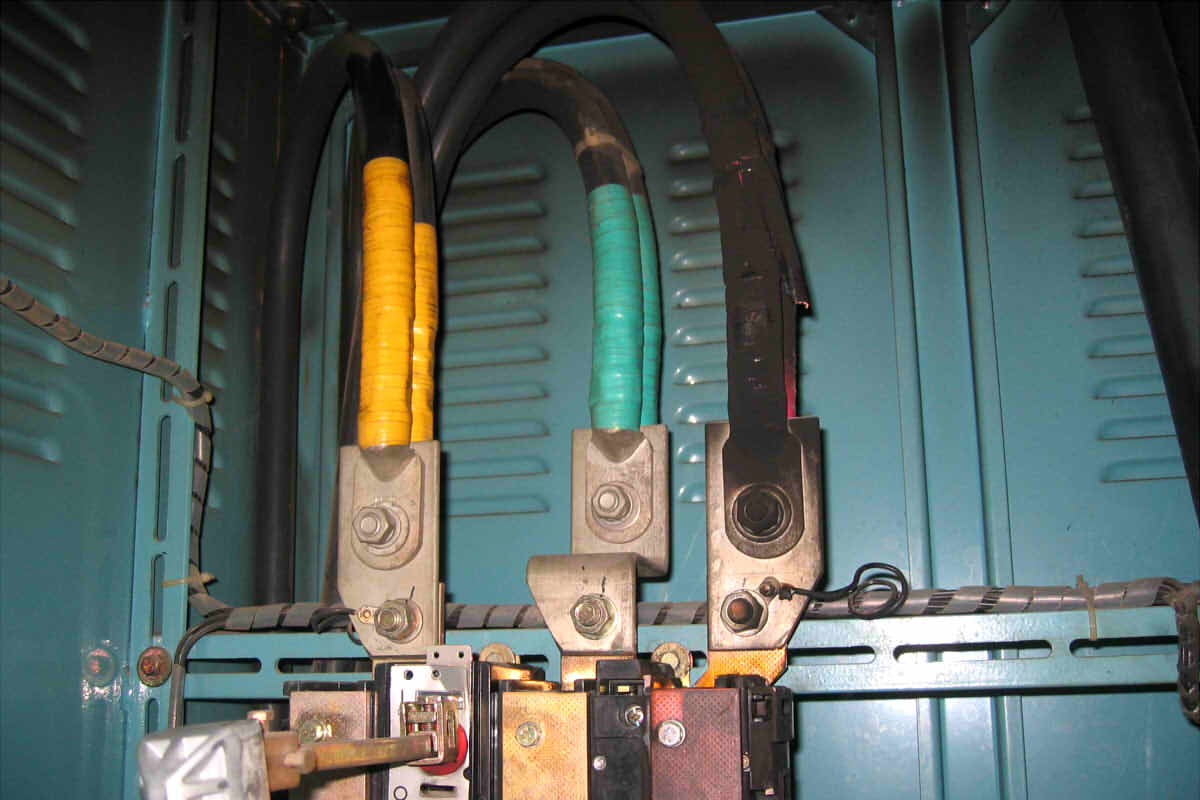

Thus, The electrician calculated that the theoretical current rating of the cable was 39,4 A. This value is only approximate due to the choice of the relevant coefficient for the calculation formula. On this base, chose the copper wires 10 mm² with a maximum current capacity of 43 A. Nevertheless, ten days after finishing the project with this election, these cables suffered a fault.

After ruling out the quality of the cable itself, The electrician focused the problem on the calculation itself. It was then that he realized that he had overlooked a very important aspect of real use: The boot and stop frequency frequency was very frequent.

The starting current generated during the start -up of a loading engine is 5-7 times the value of the nominal current. This causes currents far superior to nominal value frequently affect the chosen cable, what inevitably damages the cable over time.

In combination with the real situation, The electrician changed to the cables of 16 mm² of section and no more failures occurred.

Case 2: Incorrect Selection of Cable Structure

Plus cable charging, the wrong selection of the cable structure it can also make it impossible to ensure long-term safe use. Once there was a breakdown in a mine due to the incorrect use of cables.

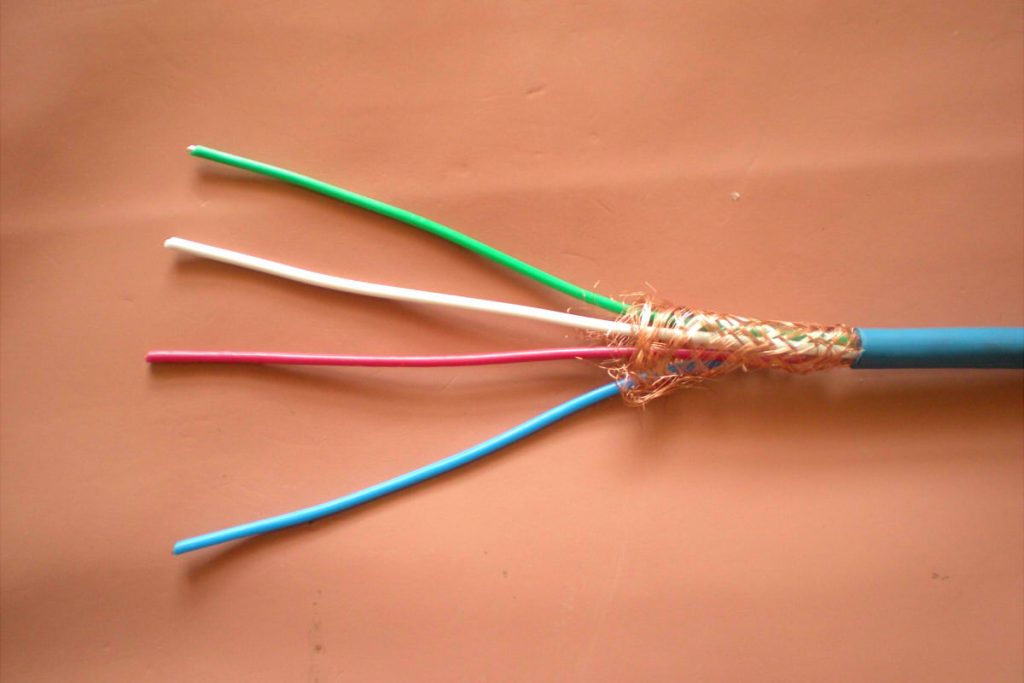

The mine introduced a joint control unit controlled using the serial communication protocol RS485. In the process of wiring communication lines (RS485+, RS485-) between the central computer and the four extended drives, the mine electrician assumed that the fire-retardant cables (all three conductors and four wires) used in the underground mine were perfectly capable of performing the task.

Nevertheless, after installation, The device failed from time to time with associated failures. The mining company attributed the problem to the quality of the joint control unit. Nevertheless, When unit maintenance personnel tested, discovered that there was a problem with the cable used.

To avoid electromagnetic interference, as well as the characteristic geomagnetic interference of underground mines, The installation manual specifies that the communication control wiring must use the communication cables intertwined with metallic shield. Depending on the communication distance, additional compensation resistances are also required if necessary.

The electrician had only taken into account the flame retardant requirements of the cable, but had neglected shielding requirements. After replacing the cables with new ones shielded communication cables, the installation went back to normal.

Resume

These two cases of cable-induced failures demonstrate the importance of cable selection.. ZMS reminds you that, when choosing a cable, You must consider a number of factors to determine the specifications and structure of the cable based on the actual requirements of the application.. If you have any questions about the selection of electrical cables, you can consult our cable experts. They will give you specific advice based on your application requirements to ensure reliable use of the cable..