The OPGW fiber optic cable is the future of electrical connectivity. Reliability and applicability come together in an innovative solution that has revolutionized electrical systems. ZMS reveals the secrets of OPGW fiber optic cable installation!!

Table of Contents

- What is OPGW Fiber Optic Cable?

- Installation of the OPGW Aerial Cable

- Key Points for Quality Control in OPGW Installation

What is OPGW Fiber Optic Cable?

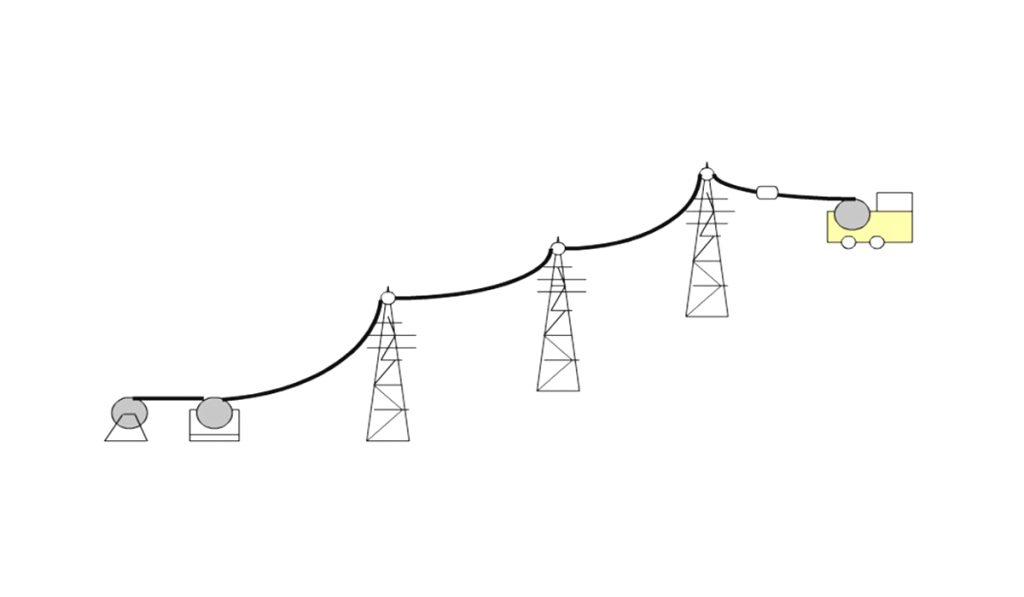

El OPGW cable, aka fiber optic composite overhead line. It lays the optical fibers on the ground line of the high-voltage transmission lines and installs them on the top of the transmission towers to form a fiber-optic communication network on the transmission lines.. This structure combines ground line and communication functions, and is generally referred to as fiber optic OPGW.

OPGW fiber optic cable is wrapped in metallic conductors, which makes it more reliable, stable and solid. Because the overhead line and the fiber optic cable are combined into one, compared to other types of fiber optic cables, not only the construction period is shortened but also construction costs are saved.

Besides, si se utiliza OPGW braided cable with aluminum-coated steel wires or aluminum alloys, is equivalent to installing a good conductive ground line, which provides several benefits, how to reduce eddy current in transmission lines, reduce power frequency surges and improve interference and hazards to communication lines.

Application of OPGW Fiber Optic

OPGW is suitable for high voltage lines greater than 110 kV and with large distances between the towers (usually more than 250 m). It is easy to maintain and solve line crossing problems. Its mechanical characteristics allow large line crossings. The outer layer of the OPGW is metal-armed and is unaffected by high-stress corrosion and degradation..

The OPGW must be disconnected during construction, which implies considerable energy losses, Therefore, OPGW should be used in new high voltage lines of 110 kV or more. To add new optical fibers in old lines, you can use the ADSS fiber optic cable.

The material of the optical fiber is fiberglass., it is brittle and breaks easily. During the construction process, the OPGW must be prevented from stretching, scratch off, Tuerza, crush or double. Fiber optic cable should be pulled smoothly without being subjected to significant compression.

Installation of the OPGW Aerial Cable

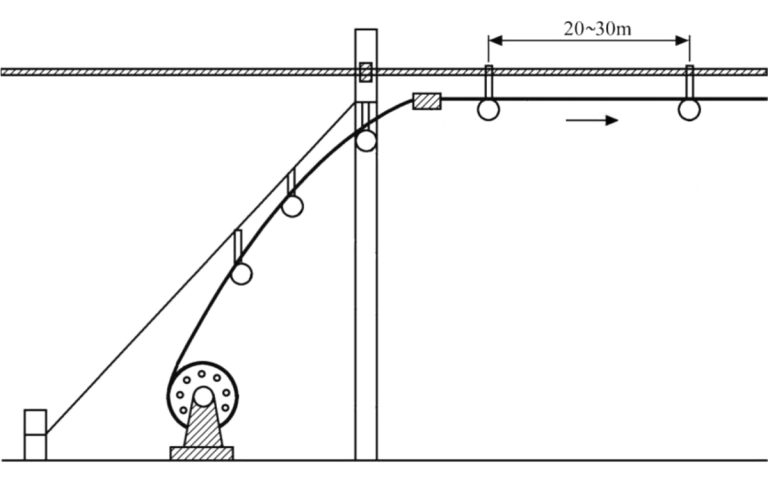

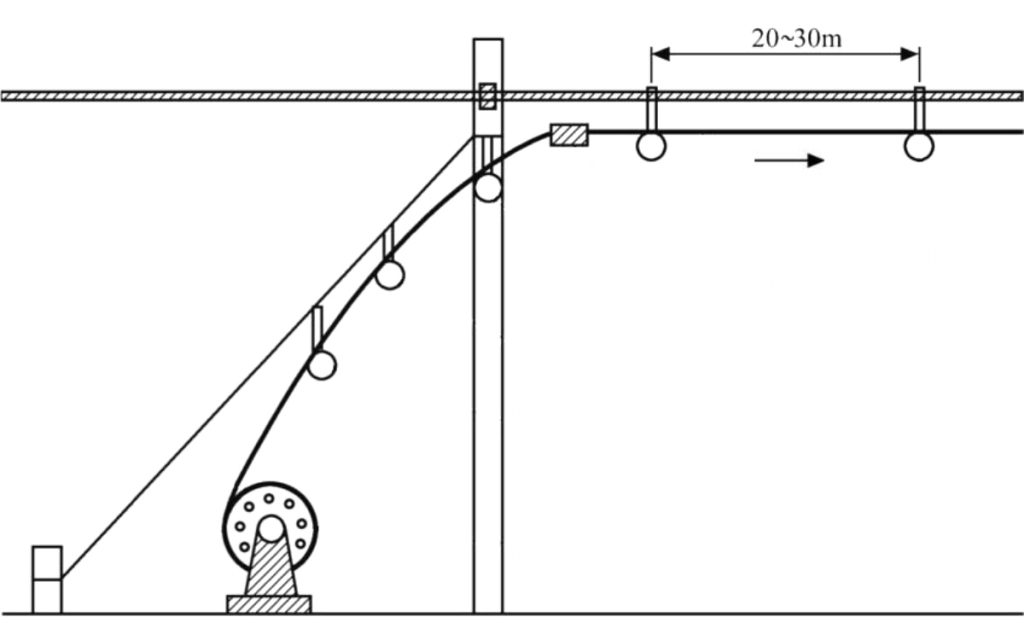

The commonly recommended installation method for the OPGW is the pull-and-tension method.. This method involves applying a constant tension to the OPGW throughout the stringing process.. This way, ensures that there is enough space between the cable and obstacles or other objects to avoid friction and damage to the OPGW. Besides, this method helps to reduce manual labor intensity and improve construction speed. The installation process consists of the following steps:

Laying of OPGW Cable by Guide Rope

Insert the OPGW fiber optic cable from above towards the wheels of the tensioning equipment, encircle the tension roller six times and pull it out from above. Connect the output end of the ground wire with a pull braid coupler and use a twist coupler. 30 kN to connect the guide rope with the tension mesh coupling.

Insert the front end of the guide rope from above towards the winding pulley, wrap around the winding pulley six times and guide it from above to the guide rope reel. Install a grounding pulley on the guide rope and fiber optic cable. With all the preparations done, start laying at a slow speed. After the torsion device and cable end traction mesh are passing the first tower smoothly, laying speed can be gradually increased to 30 meters per minute.

When the guide rope attachment is close to the pulling equipment, reduce laying speed so that the coupling slowly passes over the take-up sheave of the traction equipment. When the coupling has passed 2-3 turns around the spool of the guide rope, stop laying temporarily. Fix the guide rope in position in front of the towing equipment with a guide rope tensioner. Disconnect the guide rope swivel coupler and remove the filled guide rope spool, replacing it with an empty guide rope spool.

Wrap the end of the guide rope around the empty spool and pull it taut. Once the traction equipment is under load again, stop it temporarily, remove the guide rope tensioner and then continue stringing. After the cable has crossed the last tower, Sufficient length should be left for testing and connections. The retention length at the end of the laying is equal to the height of one more tower 10 metros.

Stop laying and anchor the ends of the aerial fiber optic cable on the stakes using rope tensioners. Install a manual winch 30 kN in series on the ground of the anchored cable and tension it to maintain the tension of the ground cable or guide rope. Remove the guide rope.

Aerial Fiber Optic Cable Tensioning

Once the OPGW fiber optic cable has been laid, the cable must be tensioned quickly. Tensioning should be done during the day, in fogless weather, rain or strong winds.

The tensioning procedure is as follows: leave enough cable length at the anchored end, which must be equal to the height of the tower plus 10 metros. Then, place a suspension clamp on the side of the cable that will be tensioned.

When several suspension segments that have not been disconnected are stressed, the method of tensioning from far to near must be used: after tensioning the suspension segment furthest from the tensioning point, mark the second suspension bracket on the second tower and place the suspension hardware on the side where the tensioning has already been completed. Then, release the tension on the side where the tensioning has already been carried out, remove the laying rollers one by one and proceed to install the hanging accessories and ground cables on each tower. Leave enough cable length (1.2 times the width of the crossbar) on the suspension tower and then install the suspension clamp and hang the cable on the side where the tensioning will take place. After, tension the next suspension segment, and so on.

During the tensioning process, OPGW fiber optic surface should be protected with rubber tubing to avoid damage. A suitable counterweight must be added during operation to prevent the OPGW from winding up.. Besides, at the end of the cable coming out of the suspension clamp, should be tied with a nylon rope to the winch chain to prevent excessive bending of the cable.

Observation and Adjustment of the Cable Chain

Adjust the temporary lines on the anchor tower so that the suspension point of the crossbeam will deviate 30 a 50 mm to the opposite side of the force. Start the winch and tension the OPGW cable. When the observed catena approaches the design value of the catena, stop pulling and observe the OPGW catena until it meets the design requirements.

Installation of Accessories and Hardware for the OPGW

Hardware types commonly used in OPGW fiber optic cable installation include suspension hardware, damping fittings, cable protectors, guide fasteners, ground wires, intermediate junction boxes, terminal boxes, among others. It is especially important to note that during laying, traction, chain adjustment and tensioning, suspension accessories specific to the OPGW must be used to avoid damaging the cable.

To prevent vibration and cable wear, the residence time of the OPGW on the rollers must not exceed the 48 hours after stretching. Tensioning accessories can be reused up to three times, depending on operating conditions. Nevertheless, accessories for permanent use in the project must be completely new.

Key Points for Quality Control in OPGW Installation

- The installation of OPGW fiber optic cable is similar to that of power lines. During the installation, the original power line should be turned off, and it is prohibited to work in adverse weather conditions such as strong winds, storms or extreme temperatures. The bending radius of the fiber optic cable must be at least 0.5 metros.

- during construction, fiber optic cables must be prevented from entangling each other and damaging the outer jacket layer of the cable. The dynamic bending should not be less than 40 times the diameter of the cable, namely, during construction a radius of curvature of at least 600 mm and the OPGW must not be twisted. In places where the OPGW crosses traffic lanes, communication lines or power lines, A responsible person should be designated to oversee. Fiber optic cable must be kept at a safe height to avoid collisions or being crushed by vehicles, which could endanger the safety of the cable and people.

- The crossing distance above the ground for the laying of the OPGW cable aéreo must meet the following requirements: in areas without traffic, the OPGW must be at a height of at least 3 meters above the ground; on pedestrian roads or roads with little traffic, the OPGW must be at a height of at least 5 meters above the ground; on highways and railways, the OPGW must be at a height of at least 7.5 meters above the ground.

- During the construction process, attention should be paid to the protection of the outer sheath layer of the cable. Aluminum clad steel wire or outer layer aluminum alloy are the components that withstand surge current and lightning strikes. if they get damaged, may represent a long-term risk to the pipeline. Rollers should be checked for burrs; the cable must not be thrown or thrown violently; when using the blood pressure monitor, attention should be paid to protect it with a rubber sleeve. The OPGW reel should be placed on a swivel stand or cable trolley, and the distance between the reel and the center of the tensioning machine must be 5-8 metros.

- Every day, a reel of OPGW fiber optic cable must be guaranteed to be completed. If it is necessary to leave it overnight or for a long period of time, the OPGW must be secured to the rollers with nylon ropes to prevent it from slipping and that the optical fibers at the point of contact with the rollers suffer fatigue damage. At the same time, temporary anchorages must be made at both ends of the traction cable and the fiber optic cable. The OPGW slack between the anchorage point and the tensioning machine at the tensioning end must be sufficient to release the tension in the traction rope.. It shouldn't be too loose, and the fiber optic cable must not be dragged on the ground.