The Changji-Guquan high voltage direct current transmission line of China is the highest voltage level project, largest transmission capacity and longest transmission distance in the world.

What's Special about the High Voltage Overhead Line of ±1100 kV?

The Changji-Guquan project is the first in the world to raise DC voltage to ±1100 kV and transmission capacity to 12 million kW. This power line has 3.324 km long.

Compared to the ±500 kV transmission EHV DC, the transmission distance of ±1100 kV UHV DC has increased between 5 Y 6 times and transmission capacity has increased between 4 Y 5 times. Its transmission loss is less than 1/4 of the ±500 kV line, corridor width per unit capacity is just the 55% of it and the unit cost is only the 40% Of the same.

Los 12 million kW of transmission power of this DC high voltage line allow to supply daily 192 million kWh of electricity to other regions. This is equivalent to burning 60.000 tons of coal, that could meet the electricity needs of 71 million residents for nearly 2 days.

How Much Electricity Has This UHV Transmission Line Transported??

The Changji-Guquan project of UHV DC transmission has transported 5.414 million kWh of electricity in January 2023. The daily average reaches 174 million kWh, which means an increase in 27,4% compared to the same month of 2022. Until now, this UHV line has supplied a total of 175.851 million kWh of electricity, 55.064 million kWh in 2021 Y 63.207 million kWh in 2022.

The project supplies eastern China with more than 60.000 million kWh of electricity per year. It can meet the electricity needs of 50 million homes. At the same time, these powers can reduce the transport of coal in 30,24 millions of tons. They can also decrease 59,4 million tons of carbon dioxide, 149.000 tons of sulfur dioxide and 157.000 tons of nitrogen oxides. This effectively helps prevent and control air pollution..

Structure of Changji-Guquan Power Transmission Line

The conductors of this ultra-high voltage line are made up of eight divided wires with a large cross section of 1250 mm². The thickness of each wire is approximately that of a human wrist..

Based on design specifications and various parameters, the total aluminum cross section of the ±1100 kV conductor is originally calculated to be greater than 6061,1 mm². Since there is not a single conductor with such a large section, you have to use the split conductors.

Split wires are usually made up of several conductors with smaller sections per phase or pole. This corresponds to an increase in the total cross section of the cable. And this is less prone to electrical corona than a large conductor with the same total cross section.. It also increases the transmission capacity of the line and improves its stability..

Due to the length of the power lines of ±1100kV, if the cross section of the conductors is too small, the line voltage drop is large. This can make streaming over the line less efficient.. Power lines with transmission efficiency less than 93% they are not cheap.

Through a comprehensive comparison of each wire size, The project uses the solution of steel core aluminum stranded cable from 8 x 1250, optimal from the economic and technical point of view.

Work with Electricity under High Voltage Lines

What damage would a power outage cause on this power transmission line?? It is estimated that the line will take at least 12 hours to suffer a blackout and maintenance, which will affect the supply of 100 million kW of electricity. Electricity losses alone could amount to 40 RMB million.

Avoiding power cuts can only be achieved by doing work with electricity. The work with electricity in ultra high voltage lines is based on two main tools: helicopters and protective suits.

Helicopter Assisted Operations

High voltage transmission towers are tall and large. If you just trust the handyman to climb the tower, it is likely that when you go up you will be physically exhausted. Thus, in recent years, the operation is usually assisted by helicopters.

Helicopter-assisted operations are currently a means of operation used in some countries for the maintenance and repair of electrical networks.. It is characterized by fast and efficient operation. This method is less affected by terrain and can significantly reduce the time it takes for personnel to climb the towers. It also greatly reduces the difficulty of operation and significantly improves the safety factor and maintenance effectiveness..

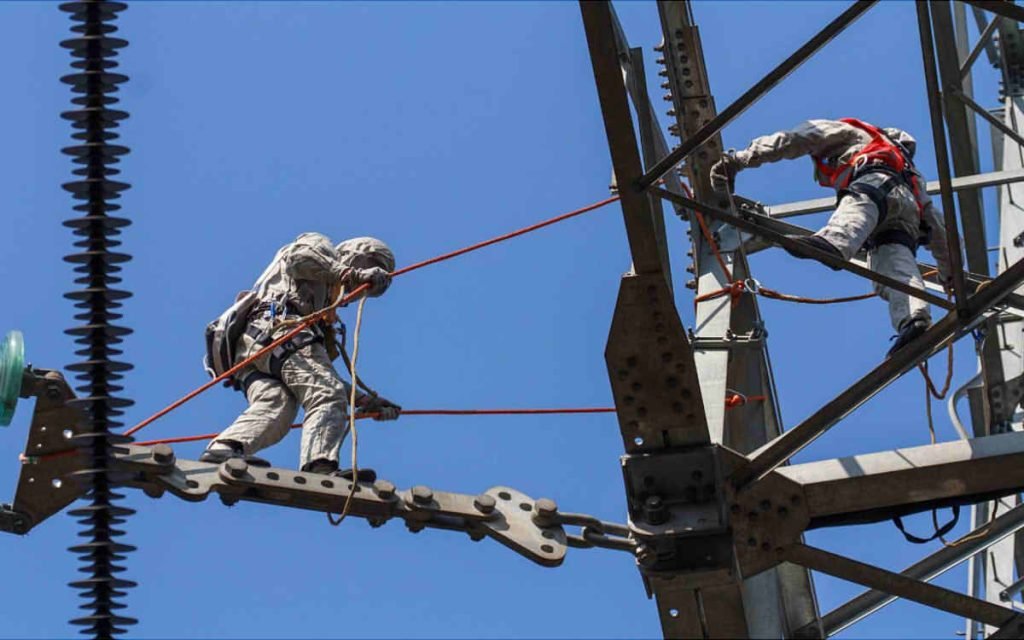

Shielded Protective Suit in Operations with Electricity

Usually, high surface field strengths occur when the human body is near live conductors. And due to the complex shape of the human body and the different distances between various parts of the body and the charged conductor, the intensity of electric field it is different in each part. If shielding protection measures are not taken, operator's skin will feel strong numbness and irritation.

The shielding suit is a clothing made of evenly distributed conductive materials and flame retardant fiber materials.. The use of the protective suit creates an equipotential shielding surface on the surface of the body, protecting it from high electric fields.

The protective clothing is in the form of a one-piece suit. Consists mainly of shielding clothing, gloves, shoes and socks. Besides, the protective suit must also be resistant to perspiration, to washing and electric sparks.

The Future of Ultra High Voltage Lines

In the future, the global network of energy built with lines UHV as backbone will promote the development of global clean energy bases. The interconnection of international electricity networks can favor the integrated development of energy networks, transport and information. This will mean a new contribution to solving global challenges such as the scarcity of resources, environmental pollution and climate change.