MICC Cable

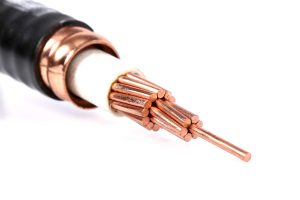

The MICC cable, aka MI cable, It is a mineral insulated cable.. These cables are constructed of a solid copper or nickel-chromium conductor that is insulated by magnesium oxide (MgO). This gives them exceptional fire resistance and durability..

ZMS insulated wires with mineral are designed to withstand extreme temperatures and harsh environments. This makes them ideal for use in industries such as oil and gas., chemical processing and power generation.

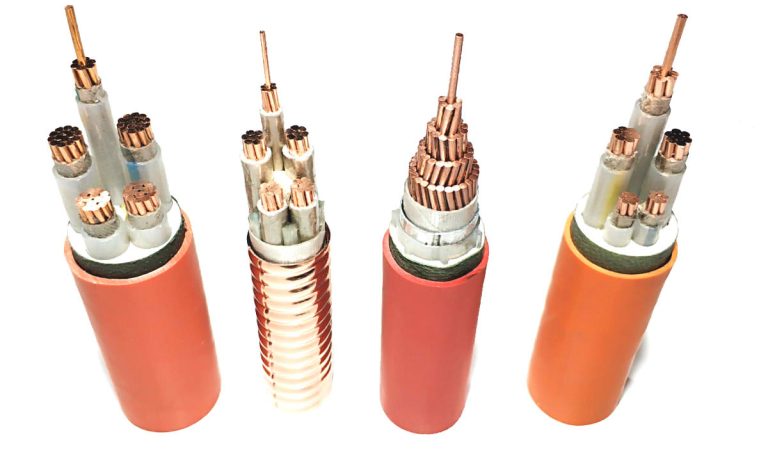

MICC Types ZMS Cable

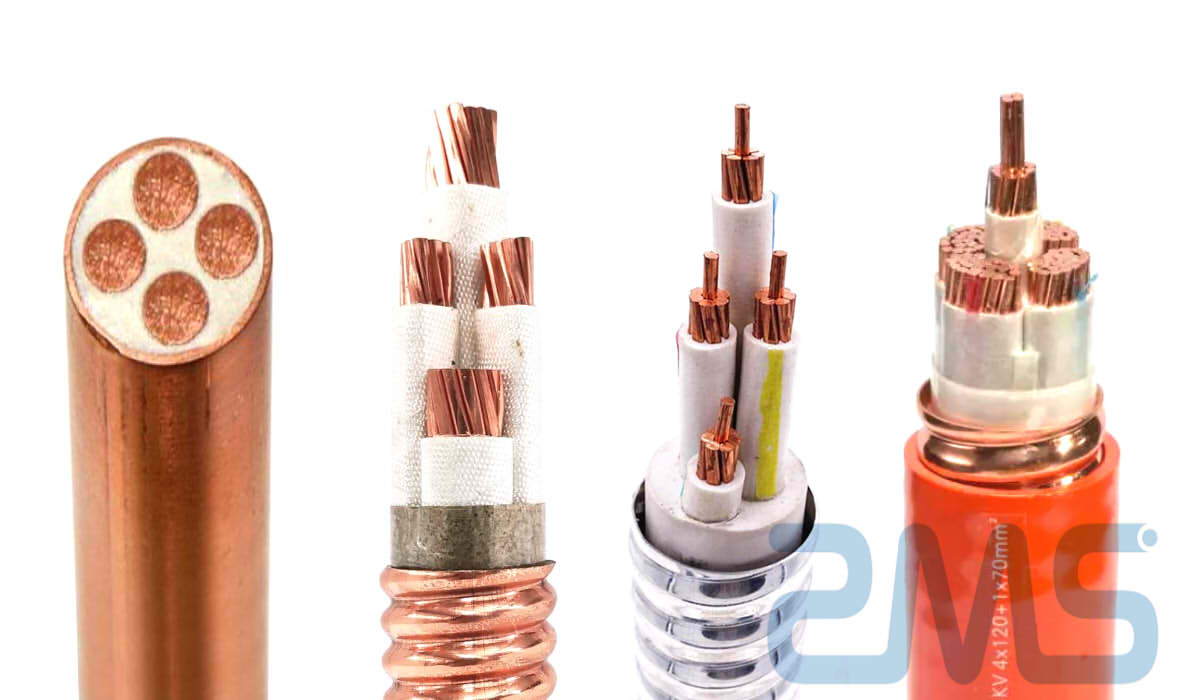

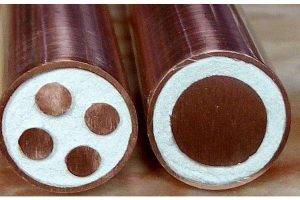

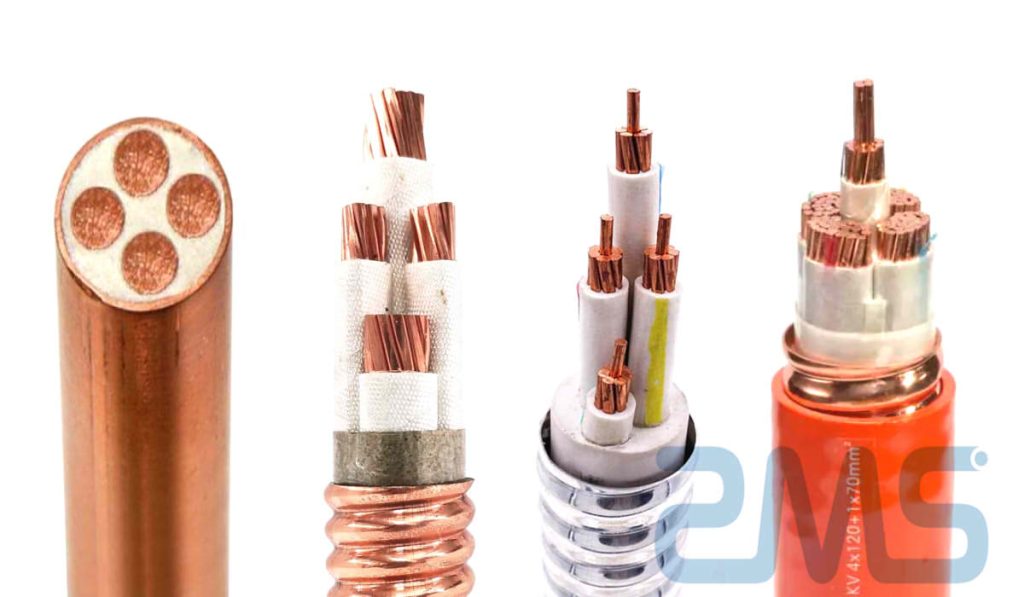

MICC Copper Tube Sheath Cable

This mineral insulated cable is composed of the solid copper conductors, magnesium oxide insulation and a seamless copper tube cover.

Type: BTTZ, BTTQ, BTTVZ, BTTVQ

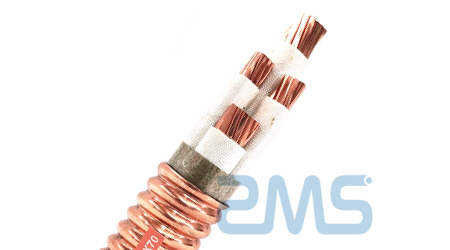

MICC Corrugated Copper Ribbon Cable

It is made up of copper conductors., fluorinated mica tape insulation and a copper corrugated tape cover. A LSZH polyolefin sheath can be added when it is required that the metal cover is not exposed.

Type: YTTW, BTW, BTTRZ

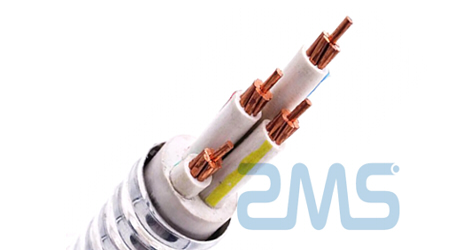

MI Cable with Aluminum Tube Jacket

This type of MI cable is made up of copper conductors, mica tape insulation, seamless aluminum tube cladding, low smoke halogen free jacket and oxygen barrier fill.

Type: RUSSIA, BTLY

Technical Specifications

- Conductor: Solid copper or nickel-chromium

- Isolation: Magnesium oxide (MgO)

- Rated Operating Temperature : ≤250°C

- Maximum Operating Temperature: 950℃(180 minutes)

- Cable Bend Radius: No inferior a 6 times the outer diameter of the cable

- Lifespan: Superior a 70 years

- standards: BS 6207, BS 6387, IEC 60331-11, IEC 60702-1, IEC 60754-1, etc.

Why Choose ZMS MICC Cable?

Superior Fire Resistance

Copper has a melting point of 1083°C and mineral insulation also has a melting point above 1000°C. So, MICC cables are highly resistant to fire. Magnesium oxide insulation used in ZMS MI cables provides excellent fire resistance, ensuring maximum safety in hazardous environments.

Corrosion Protection

Mineral insulated cables have a seamless metal jacket. Selection can be based on actual job site conditions by choosing the proper metal outer jacket to prevent cable corrosion.

Explosion Resistant

Since MI cables use a metal jacket as a protective layer, flammable gases, oil vapor and flame cannot reach electrical equipment connected to the cable. Therefore, cables are explosion proof.

Great Load Capacity

The diameter of MICC cables is smaller than that of other plastic insulated cables with the same current rating.. For cables of the same section, ZMS mineral insulated cables can carry higher currents. At the same time, MI cables can withstand higher overloads.

grounding

Thanks to the continuity of the copper jacket and the extremely low resistance to ground of the MI cable, can be used as a ground conductor and does not require a separate ground connection.

Unmatched Durability

ZMS MICC cables are constructed of high quality materials and are designed for long life. The properties of the materials that compose it do not pose problems of aging of the insulation. So, has long-term stability.

Wide Applicability

Mineral insulated cable is explosion resistant, to the fire, the water, to corrosion and radiation. ZMS MICC cables are tested to the highest industry standards and precision manufactured to ensure maximum performance and durability..

Expert Technical Support

ZMS team of experts offers support and guidance throughout the selection and installation process of MI cables. We understand that each application is unique and we will work with you to find the best solution for your specific needs..

Common Applications of MICC Cable

ZMS mineral insulated cables are the ultimate fire fighting solution for the most demanding applications in industries such as oil and gas, chemical processing and power generation. With superior fire resistance, unmatched durability, improved reliability and expert technical support, ZMS MICC cables are the ideal choice for any application where a high level of safety and performance is required..

ZMS Commitment

ZMS firmly believes that quality is our key value.. ZMS electrical cable supplier controls, reviews and supervises all purchasing processes, production, quality and logistics to ensure full compliance with customer requirements. Our dedicated team of engineers and researchers is committed to continually evolving technology by updating materials and components to stay consistent with the latest products.. ZMS embraces best practices, the latest technologies and innovations to ensure our products deliver on the promise of sustainable development.

Consulting Program Service

We offer free consultation and free cable engineering solutions. You can ask us any questions about the cable. The company has perfect pre-sale management and after-sale technical support. It has a team of high-quality cable technology.

Fast Transportation Service

We have a stable and cooperative transportation department to ensure efficient and fast delivery of our cables.. If you have special shipping requirements, we will customize the shipping method that suits you.

Regular After Sales Service

When our quality cable reaches the destination, we will provide you with after-sales service. We guarantee that your cable will last a long time. If at any time you experience a problem with our products, feel free to contact our customer service team. We are committed to responding to your inquiries and concerns in a timely manner and resolving any issues you may have..

Learn More about MICC Cables