Electrical flame retardant cables can prevent fire from spreading along the cable and prevent the fire from spreading. Due to its low cost, are a variety of cable widely used in various applications. This type of cable has different performance test standards that can meet different fire resistance requirements..

Flame Retardant Performance Standards for Cables

IEC60332 Combustion Standards and Tests

To evaluate the performance of the flame retardant wires and cables, the International Electrotechnical Commission (IEC) has developed three different standards: IEC60332-1, IEC60332-2 e IEC60332-3.

Flame retardant performance grades IEC60332-1 and IEC60332-2

IEC60332-1 and IEC60332-2 are used to assess the flame retardant capacity of a single cable when laid inclined or vertically.

The vertical burning test for a single cable/wire in accordance with IEC60332-1/BS4066-1 includes the following:

A sample of wire rope is fixed vertically 60 cm long inside a metal box with a front opening. A propane burner with a flame length of 175 mm and is placed at an angle of 45 degrees in relation to the cable, at a range of 450 mm from the fixed end of the sample. If the burned part of the sample does not extend more than 50 mm from fixed end, the test is considered passed.

IEC60332-3 flame retardant performance grades

Any UL listed cable that has been tested and verified to meet a certain fire resistance rating may be stamped with the UL identification., the fire resistance classification and the approval number. The IEC60332-3 standard is used to assess the fire resistance capacity of bundled electrical cables when they burn vertically. High fire resistance capacity is required for bundled cables that burn vertically.

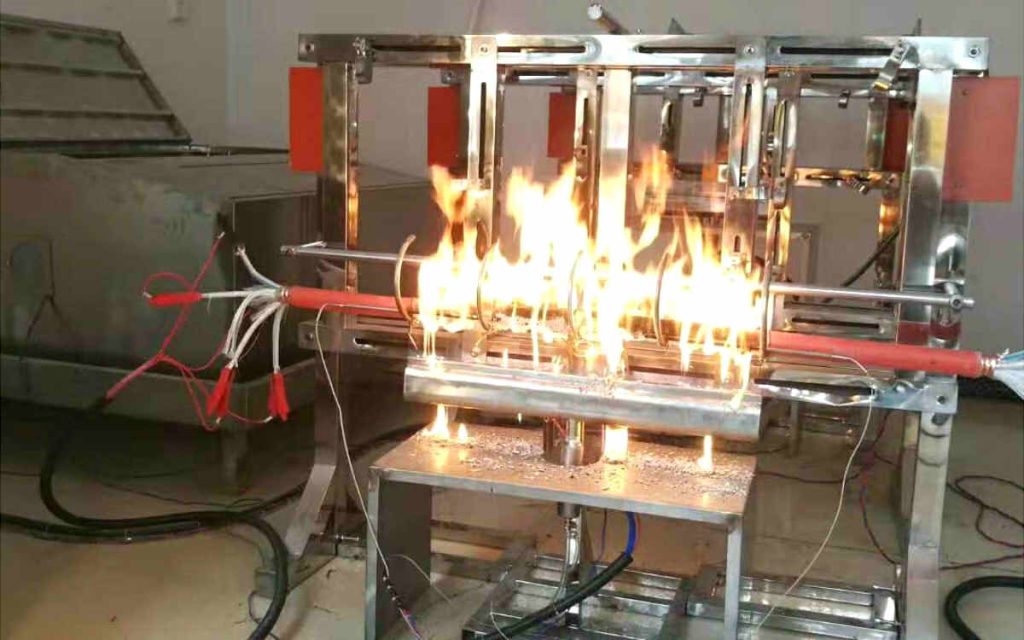

The content of the vertical burning test for IEC60332-3/BS4066-3 bundled cables is as follows:

The sample cables grouped in a bundle of 3,5 meters in length are attached to a test frame in the form of a trapezoid with iron wire. The number of test samples is determined according to the requirements of non-metallic materials of different categories.. Test samples are hung vertically on the rear wall of the combustion furnace, and air is drawn into the combustion furnace through an inlet in the bottom plate. Flat propane burning furnace contacts test sample at 750°C, and the test sample must be burned within a period of 20 minutes under the effect of forced airflow (the air emission rate is 5 m3/minute, the wind speed is 0,9 m/second). The cable should extinguish itself within 2,5 meters from the spread of the flames.

UL Flame Retardant Tests and Standards for Cables

UL fire resistance standards for cables and the corresponding tests are as follows:

Nivel CMP

The CMP level is tested using the plenum flame test / steiner tunnel (Plenum Flame Test / Steiner Tunnel Test). The applicable safety standard for electrical flame retardant cables of this level is UL910..

Nivel CMR

The CMR level is tested using the standpipe flame test (Riser Flame Test). The applicable safety standard for commercial electrical flame retardant cables of this level is UL1666.. These cables do not have smoke density regulations and are generally used for vertical and horizontal cabling in buildings.. Its flame retardant properties are better than those of low smoke and halogen free materials according to IEC standards 60332-1 e IEC 60332-3. Besides, cables of this grade burn with a low concentration of smoke.

Nivel CM

The CM level vertical burning test (Vertial Tray Flame Test) used for commercial grade cables in the UL standard. Its applicable safety standard is UL1581. This type of cables is generally used only for horizontal laying on the same floor and is not used for vertical laying on different floors..

Nivel CMG

The CMG level vertical burning test (Vertial Tray Flame Test) is used for general purpose cables (General Purpose Cable) in the UL1581 standard. Test conditions are similar for commercial grade and general purpose cables, and are accepted in Canada and the United States.

CMX level

The CMX level is tested by the vertical cable flame test (Vertial Wire Flame Test). The applicable safety standard for household cables at this level is UL1581VW-1. These cables are for use in home or small office systems only and should not be used in bundles, but in pipes.

Differences Between Fire Prevention Ideas

The cables have as main technical indicators of fire safety the resistance to fire, the density of the smoke and the toxicity of the gases. Nevertheless, Europe and the United States have different approaches to fire safety, which translates into different evaluation criteria for fire resistant cables.

American focus

The emphasis is on the production of toxic carbon monoxide gas (CO) during combustion and in the release of heat during the conversion of CO to carbon dioxide. Therefore, controlling the amount of heat released during combustion can reduce fire hazards.

European approach

In Europe, the main factors that determine whether people can safely escape a fire are the amount of halogen acid (HCl) released during combustion, the corrosiveness of gases, the density of the smoke and the toxicity of the gases.

Despite different perspectives, the safety and environmental protection of cables are becoming more and more important. Currently, there are many fire resistant cable products, as mineral insulated cables (MICC) and low-smoke, zero-halogen cables (LSZH). The global market for fire resistant cables is expected to grow at a CAGR of 4,39% and reach the 97.252 million yuan for 2027. This demonstrates the great market potential of fire resistant cables..

1 thought on “Performance Tests and Standards for Electrical Flame Retardant Cables”

Comments are closed.