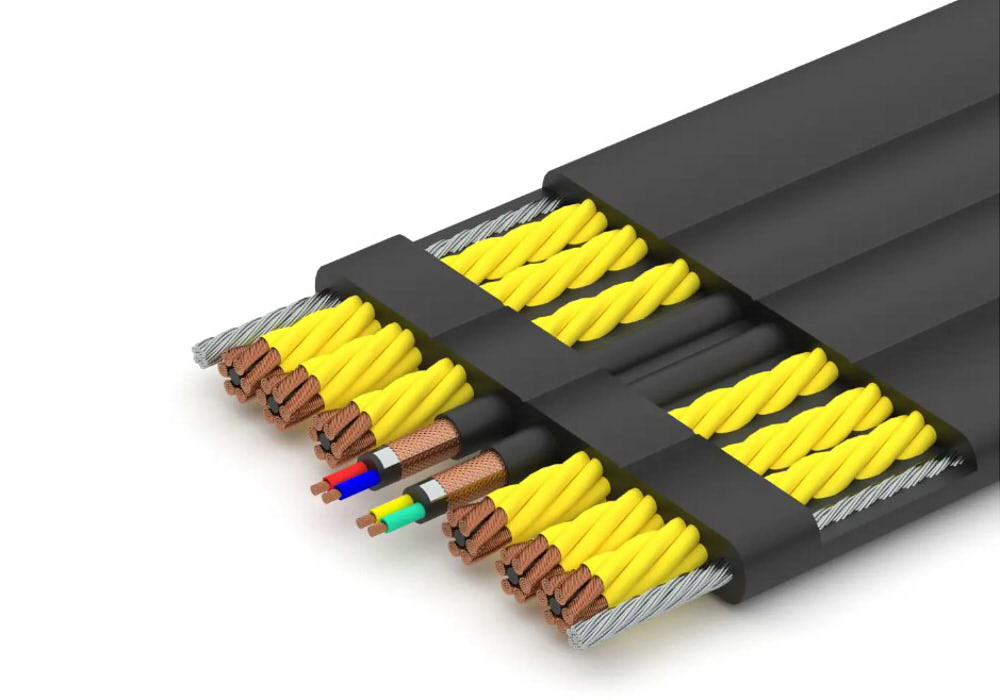

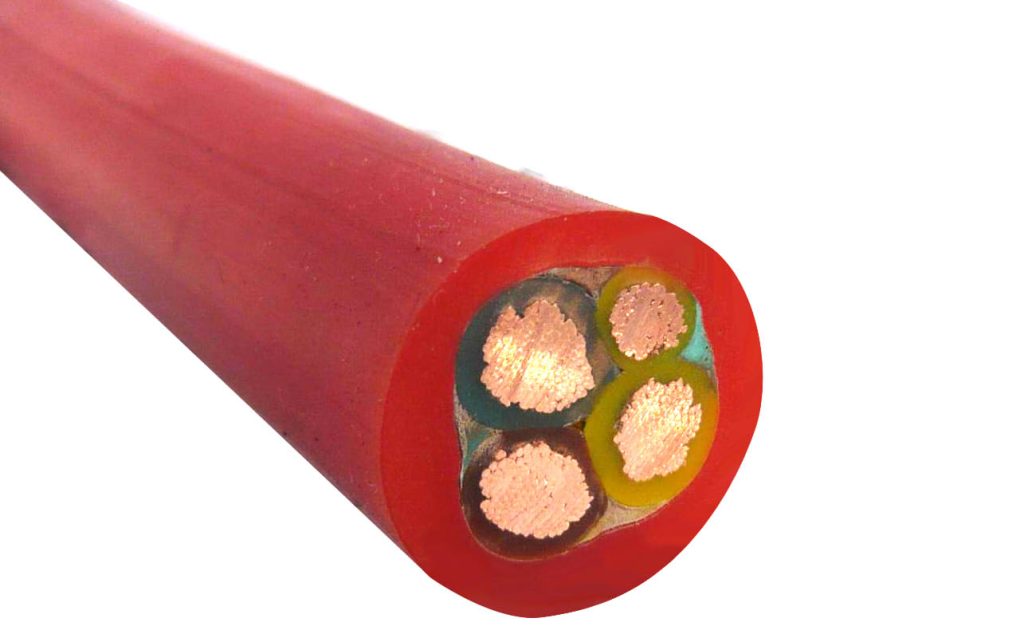

Rubber cable wrapping is the application of a rubber material around the conductor of the cable to protect it from moisture, dust and other external factors that can damage it. The rubber material used in this process is highly resistant and flexible.. This makes it an ideal choice for special electrical and communication cables..

Cable glands are used in a wide range of applications, from the production of low voltage cables for electronic applications to the production of medium voltage cables for the energy industry. Los rubberized cables They are also commonly used in the oil sectors, chemical, military and aerospace, where strength and durability are essential.

The cable caulking process may vary depending on the type of cable and the rubber material used.. Usually, Rubber cables are obtained that are more resistant to abrasion and more flexible than plastic cables such as PVC cables.. And the price of rubber rubberized cable is higher than that of plastic PVC rubberized cable because the raw materials are more expensive and require more delicate processing..

Rubber Electrical Cable Rubber Materials

Chlorinated Polyethylene

Traditional resinous chlorinated polyethylene (CPE) for cable processing has a correspondingly high crystallinity and viscosity. But its application is hampered by its high Mooney viscosity and the difficulty of processing and extruding the material. In recent years, The industry has successfully developed elastomeric chlorinated polyethylene (CM). It is especially suitable for cable sheathing due to its flame retardancy and weather resistance.. Currently, The CM special rubber has been used in a large number of special cables, as fireproof cables, mining cables and marine cables.

Nitrile Butadiene Rubber

Nitrile Butadiene Rubber (NBR) It is used in cables mainly as a resin modifier to form elastomers with some general-purpose plastics.. NBR powder has excellent dispersibility, ease of particle manipulation and refinement. Plays an important role in rubber processing, resin modification and performance improvement. Using NBR in cable compounds can greatly improve oil resistance, to the cold and abrasion of the cables.

Ethylene Propylene Rubber

Ethylene propylene rubber (EPDM) It is ozone resistant, to heat and humidity. It has great tensile strength and excellent electrical insulation properties. It is gradually replacing PVC in the production of insulated medium and high voltage cables, cable connectors and polymeric insulators. Besides, Ethylene propylene rubber has low sensitivity to UV radiation, low toxicity and excellent chemical resistance. It is important to note that EPDM is flammable and, so, requires a high concentration of flame retardant. This makes EPDM cables more expensive compared to other rubber cables..

Silicone rubber

The electrical properties of silicone rubber are very little affected by temperature. It has excellent material properties and stable insulation characteristics. That is why this rubber is often used in the manufacture of special cables.. These reliable special cables can operate for long periods in harsh environments. Silicone rubber is currently the most promising rubber material in the energy industry.. It is widely used in insulators, high performance cables and accessories. Besides, Silicone rubber is mainly used as the main material in new fireproof cables introduced by companies of cables.

Nanomodified Adhesive for Cables

Nanomodified adhesive for cables is a new type of material formed by mixing nanomaterials with macromaterials. This material can effectively improve the tear resistance of rubber, reduce the hardness of the material, increase plasticity and improve processing performance. If ZnO is used, aluminum hydroxide, Nanoscale Magnesium Hydroxide to Modify Cable Rubber, not only can they change their processing properties, but also improve the dielectric properties of rubber. This material is currently an important research direction for the cable industry..

The Future of Rubber Cable Caching

With the development of electricity, the construction, transport, the comunications, oil and other industries, Greater performance is also required from cables. Therefore, cable materials are gradually high quality, special and specialized. Currently, the cable industry moves in the direction of green development. The cable industry needs to increase research and develop rubberized materials. special high performance cables.