OPPC cable (Optical Phase Conductor) It is a type of optical cable specialized for electrical energy. This aerial cable combines fiber optic units within phase conductors, thus having a double function in the phase line and communication.

The OPPC cable is mainly used in suburban and rural distribution networks with voltages below 110 kV, especially in new lines of 35 kV. In low and medium voltage networks, especially in the distribution lines of 35 kV or less, some do not require ground lines, so OPGW cannot be installed. In these cases, OPPC becomes a suitable alternative.

OPPC technology is similar to OPGW. This type of aerial cable integrates fiber optic units into the traditional phase line structure appropriately., thus becoming an optical phase conductor.

Table of Contents

- Introduction to OPPC Cable

- Advantages of OPPC Cable

- Selection and Design of OPPC Lines

- ZMS OPPC Design Selection

Introduction to OPPC Cable

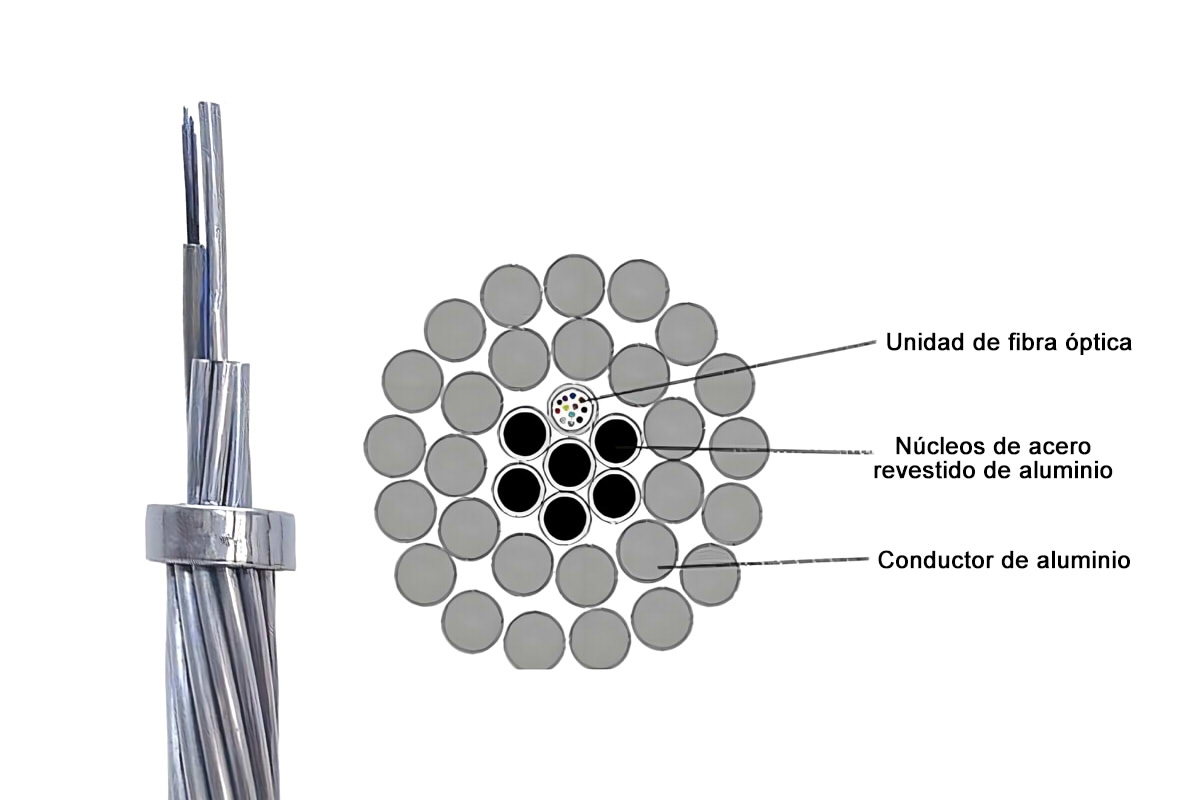

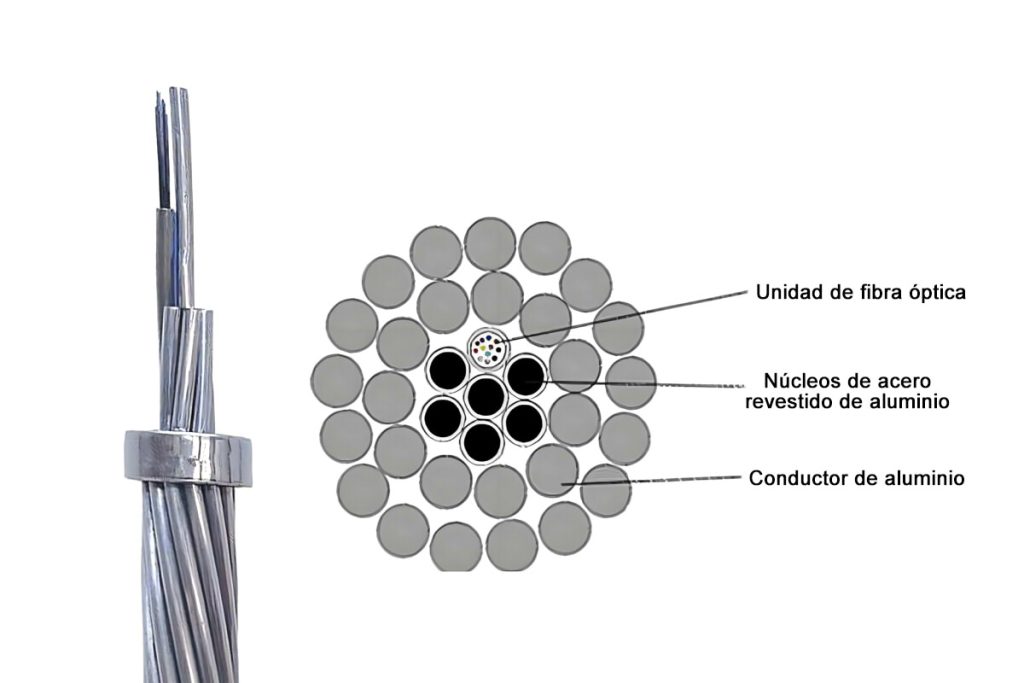

The OPPC cable replaces one or more of the steel wires in the ACSR aerial cable traditional with stainless steel tube units for optical fibers. Inside, Contains stainless steel tubes and a steel core, while on the outside it has aluminum alloy wires. The maximum capacity of optical fibers inside the steel tube can reach up to 144 cores.

OPPC aerial cable has outstanding advantages, como OPGW of the ADSS, by taking full advantage of the abundant resources of towers and routes in the electrical system. It can effectively fill the gaps in the power distribution automation network.. Besides, provides a channel for special applications such as transmission line temperature measurement and defrosting.

The OPPC conductor has a maximum use voltage rating of 420 kV and works optimally. Its use is also extensive in lines of 35 kV y 10 kV in low and medium voltage distribution networks.

Electrical performance of OPPC cable

Analyzing the structure of the OPPC conductor, its resistivity, DC linear resistance and torsion in each layer are similar to those of OPGW cable of the same specification. Because the OPPC conducts permanent direct current in the three-phase system, The usual operating temperature is higher than that of the OPGW or overhead ground line when there is no short circuit or lightning. For common stainless steel tube fiber optic units, Fiber optic oil separation rate is generally controlled at 80°C, while OPPC uses a high temperature resistant anti-corrosion lubricant, with temperature parameters generally controlled between 100°C and 120°C.

Optical performance of OPPC cable

Optical fibers in OPPC cable fiber optic units must be of excess length to ensure that they do not overstretch during use. For the OPPC, due to structural elongation caused by laying and tensioning, elongation due to thermal expansion during operation and plastic deformation due to creep, fiber optic excess length requirements are very strict. The fiber optic units in this aerial cable must have good mechanical protection to ensure that the optical fibers are not crushed.. To prevent moisture from affecting the life of the optical fiber, This should be placed in sealed tubes or take other effective measures against moisture..

Advantages of OPPC Cable

Saving

When using the OPPC cable on new lines:

- Construction and design of the line are completed in one go, which can increase efficiency and reduce project cost. Height and strength requirements of aerial towers can be appropriately reduced.

When using the OPPC cable in the renewal of existing lines:

- No need to change existing line conditions, only one of the phase lines needs to be replaced, and the performance of the OPPC is required to be basically consistent with the existing phase line. Whether the line's existing towers are safe and reliable, no large amount of inspection and calculation work required when replacing OPGW with OPPC.

Lower risk of rupture due to lightning strike

Compared to the OPGW cable aéreo, The OPPC cable is safe and reliable, equivalent to a normal phase line, and does not increase the possibility of rupture due to lightning strike.

The OPGW cable has the function of grounding and communication in high voltage lines, but lightning events can seriously affect your communication and programming, what threatens the security of the electrical grid.

Advantages in resistance to icing

Currently, on power lines, there is no effective means of defrosting for OPGW fiber optic cable. Nevertheless, when using OPPC cable, due to its higher working temperature, The icing resistance ability of the line can be significantly improved.

Security against theft

OPPC Cable Junction Boxes Operate With Line Power, They are installed on high voltage insulators and their installation position is much higher compared to OPGW and ADSS cables. Therefore, the probability of theft of OPPC junction boxes is greatly reduced.

Selection and Design of OPPC Lines

Aerial Cable Selection Principles

On power transmission lines with higher voltages, there are usually ground and phase lines. In these types of lines, the best option is to use OPGW. If for some reason OPGW cannot be implemented, the alternatives are usually ADSS and MASS.

On power transmission lines with lower voltages, there are generally no ground lines, only phase lines. In these types of lines, the best option is to use OPPC. If for some reason OPPC cannot be implemented, alternatives are usually ADSS.

Scope of application of OPPC cable

Theoretically, OPPC can be applied on lines of different voltage levels. In some areas, in backbone power system communications 110 kV a 1000 kV, OPGW has been used as ground line maturely, so OPPC is mainly used in some lines where it is difficult to choose OPGW or ADSS cables.:

- Lines of 10 kV, 35 kV and some lines of 66 kV that have no ground lines or only partial ground lines, which prevents installation of OPGW.

- Some old lines of 110 kV where it is difficult to collect line data and calculate the carrying capacity of the towers, and where it is difficult or expensive to modify the tower heads.

- Limitations such as insufficient safety distances to ground, inability to solve junctions, insufficient resistance of the towers, and frequent route changes that restrict the use of ADSS cables.

- Situations where the use of common optical cables faces theft and maintenance challenges, while carrier communication is limited by weather and terrain.

Line Design Principles

- The OPPC cable must carry permanent direct current in a three phase system, so the effect of continuous high temperature on optical fiber transmission performance and fiber service life should be considered., as well as thermal stability.

- It must be ensured that the OPPC has parameters such as diameter, weight, cross section and mechanical and electrical characteristics similar to those of the other two phase lines.

- The resistance or DC impedance of the OPPC should also be similar to that of the other two phase lines to avoid voltage changes at the remote end and maintain three-phase balance..

- Since the phase lines are energized, special insulation accessories and special junction boxes must be used at intermediate interconnections and at substation input terminals.

- To increase safety during construction and project quality, and facilitate future repair and maintenance, It is recommended that the length of the OPPC cable coils not exceed the 3 km.

ZMS OPPC Design Selection

In theory, The design of the OPPC cable is based on the number of optical fibers required by the system and then the mechanical and electrical performance parameters that the OPPC must meet are determined according to the parameters of the transmission line.. After the tender, Manufacturers calculate and adjust OPPC performance parameters according to design requirements, and once the design correspondence is confirmed, the cable is produced in the factory.

The OPPC has been in use for over a decade since the first line in 2005, and major cable manufacturers have their own mature parameters based on conventional conductor models.

ZMS cable supplier previously supplied an OPPC cable for a line of 35 kV, con 24 optical fibers and an aluminum conductor with a steel core with a cross section of 185 mm², using type LGJ-185/30.

If there is any question about OPPC cable selection, do not hesitate to consult our technical staff.