Southwire has been awarded a contract by Nexans (NKT) to provide a portion of the underground power cable for the CHPE project (Champlain Hudson Power Express), for which NKT is the full cable supplier and owner of the cable system technology.

The CHPE Project

CHPE is a transmission project that will deliver 1,250 megawatts of clean, renewable hydropower from the US-Canada border to Queens, NY. This is enough electricity to supply more than 1 million homes in new york.

CHPE will use a combination of submarine cables and underground cables to deliver clean, renewable hydroelectric power through a high-voltage direct current transmission system (HVDC) totally buried that extends along 339 miles.

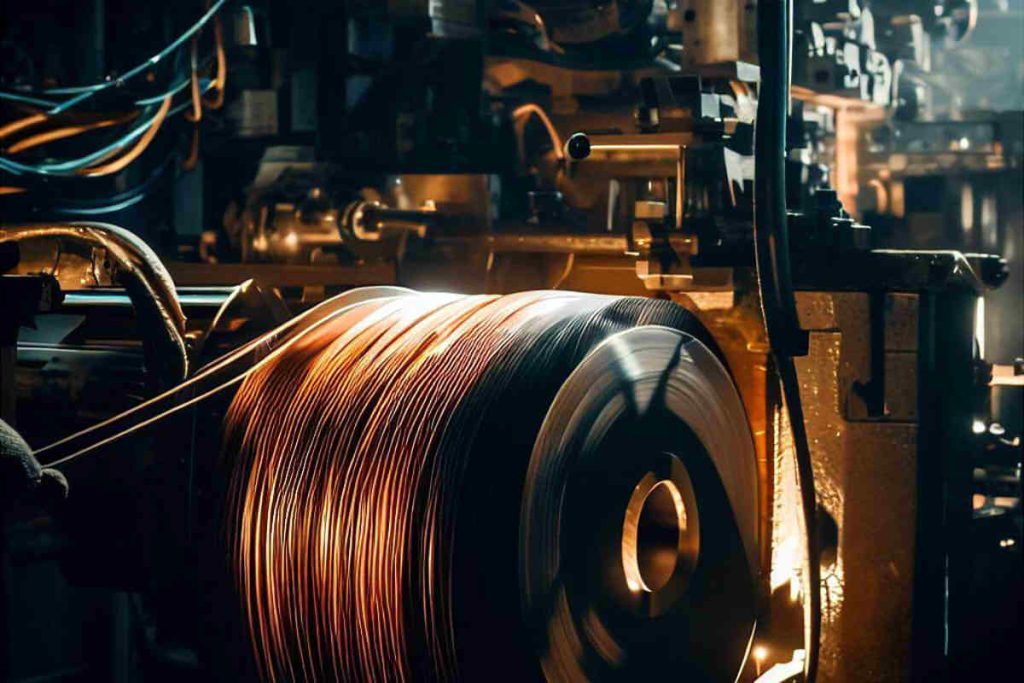

As part of the association, Southwire will manufacture the cable at its Huntersville facility, North Carolina.

Southwire and NKT Partner to Fuel Growth in Renewable Energy

“as i have said many times, This is an excellent time for our industry and for Southwire.. We are honored and excited to partner with NKT and support one of the largest renewable energy projects in the nation.”, stated Rich Stinson, Southwire President and CEO. “In addition to the significant economic benefits that CHPE will bring, it is rewarding to be part of a program that focuses on efforts related to the energy transition, reducing carbon emissions and accelerating sustainable development in North America”.

“Champlain Hudson Power Express is at the heart of New York's green transition. And we are honored to be the one-stop cable system provider for this project with our leading technology in HVDC power cables“, expressed Mika Makela, General Manager of NKT North America. “The award given to Southwire was an important factor in ensuring sufficient manufacturing capacity for a project of this magnitude.. Combining our HVDC cable system technology and close collaboration between teams has allowed decades of technology development and learning to be rapidly applied to the benefit of the project”.

“CHPE is one of the most prominent renewable energy projects in the electric industry in the last decade and promises to be a model for future underground HVDC renewable energy projects.”, Norman Adkins said, Southwire Director of Operations. “We are delighted that NKT has contracted Southwire to manufacture the majority of the underground HVDC cables associated with this exciting project.. The strategic investment in our installation of Huntersville, North Carolina, was made with this and similar projects in mind, and we look forward to supporting NKT and our customers in the North American market today and for years to come.”.

Impact of Renewable Energy Development on the Cable Industry

The CHPE project represents a major milestone in the renewable energy landscape and has a significant impact on the cable industry. As the demand for clean and renewable energy continues to increase, cable companies are playing an essential role in the viability of these projects.

Increased Demand for High-Tech Cables

renewable energy projects, like CHPE, require high-tech cables capable of transporting large amounts of power efficiently and reliably over long distances. This has fueled the demand for HV cables (high voltage cables) that can transport energy over long distances with minimal losses. Cable companies are investing in the research and development of more advanced cables to meet this growing demand.. Highly technical cable manufacturing is now concentrated in a few blue chip cable manufacturers.

underground infrastructure

Renewable energy projects often require the installation of underground cables to minimize environmental and visual impact.. This has led to an increase in demand for high-quality underground armored cables that can withstand the harsh conditions underground.. Cable companies are developing stronger and more durable cables to meet these requirements..

Sustainability and Emissions Reduction

The transition to renewable energy focuses on sustainability and the reduction of carbon emissions. Cable companies are adopting more sustainable practices and materials in cable manufacturing. This contributes to the goal of reducing the environmental impact of energy infrastructure..

Manufacturing Capacity Expansion

The production of highly technical cables is a complex task that requires specialized facilities and equipment. To meet the growing demand for cables in renewable energy projects, companies are expanding their manufacturing capabilities. This includes the implementation of state-of-the-art manufacturing technologies to increase efficiency and production capacity..

Strategic Collaboration

Tier 1 cable manufacturers often establish strategic partnerships with energy companies and large projects. These associations allow greater synergy in the development and execution of projects. This translates into faster and more efficient delivery of cables and transmission systems.. The partnership between Southwire and NKT on the CHPE project is a leading example of how these collaborations can make a difference.

Continuous Innovation

The cable industry is undergoing rapid innovation to adapt to the changing needs of renewable energy.. This includes the development of lighter cables, resistant and efficient, as well as the exploration of emerging technologies, such as high temperature superconducting transmission.

conclusion

In summary, the rise of renewable energy is transforming the cable industry, driving demand for more advanced and sustainable technologies. strategic partnerships, such as Southwire and NKT in the CHPE project, are examples of how cable companies are playing a crucial role in the transition to a cleaner and more sustainable future in the energy sector. Commitment to innovation and sustainability will continue to be essential on the path to decarbonizing the global electricity grid.