Fiber optic cables are today an important and indispensable part of communication lines.. For different operators and different geographical areas, The most used types of optical fiber can be different. This article introduces the different types of fiber optics, categorizing them into three main types: standard optical cables, FTTH fiber optic, and fiber optic ribbon cables.

Table of Contents

Standard Fiber Optic Cables

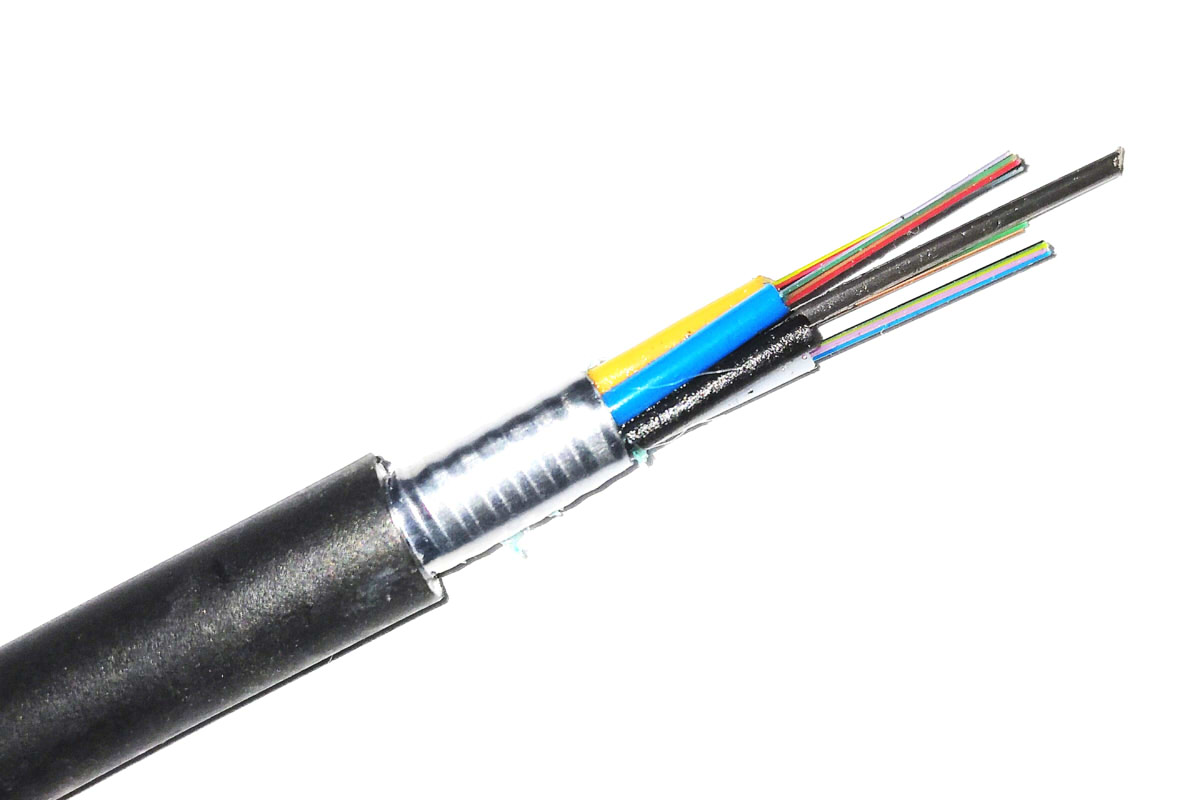

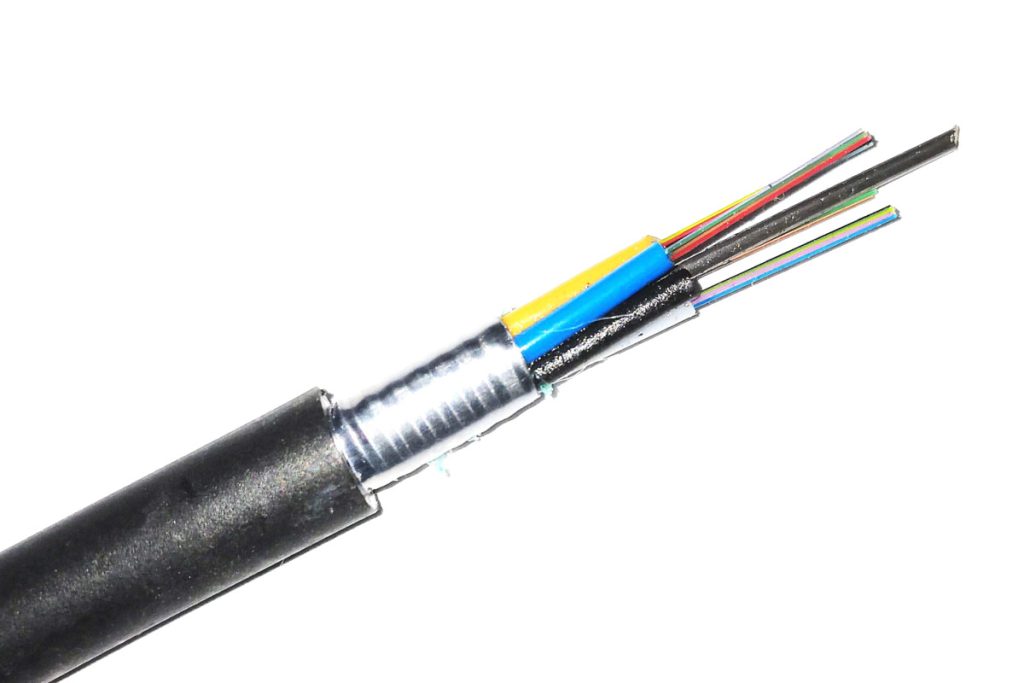

Among the most used types of fiber optics in outdoor installations are standard fiber optic cables.. They were probably the first to be widely used in communication networks.. Includes common types GYTA fiber optics (commonly for ducts), GYTS (commonly for overhead lines), GYTA53 (direct burial) and GYTZA (flame retardants).

Fiber Optic Cables for Ducts (WITH)

This type of fiber optic, known as GYTA, It has a braided cable structure. Optical fibers are placed inside loose tubes, which are filled with a waterproof compound. In the center of the cable core there is a metal reinforcement, and for certain fiber counts, A layer of polyethylene is extruded around the metal reinforcement. (PE). The loose tubes (and the filler strings) are braided around the center reinforcement to form a compact, round cable core. And the spaces inside the cable core are filled with a waterproof filling material.

After applying a plastic coated aluminum tape (APL) longitudinally, A polyethylene jacket is extruded over the assembly to form the cable. GYTA cables have good waterproof performance and are suitable for conduit installations, although they can also be used for aerial installations.

Aerial Fiber Optic Cables (GYTS)

GYTS cables have the same core structure as GYTA cables. But they differ in that their cover is made of a steel strip covered with chrome plastic on both sides. (PSP) more polyethylene.

Compared to GYTA cables, GYTS cables have better lateral pressure resistance and are suitable for scenarios where large lateral pressure resistance of the cable is required, as fiber optics in aerial installations, or for residential broadband access or for corporate customers. Although they can also be used in duct installations.

Direct Burial Fiber Optic Cables (GYTA53)

GYTA53 cables can be understood as GYTA cables with an additional jacket consisting of steel tape armor coated with chrome plastic on both sides (PSP), and finally an outer layer of extruded polyethylene. GYTA53 cables have good waterproof performance, lateral pressure resistance and tensile strength, and are suitable for direct burial installations. Because direct burial cable construction costs are high and do not allow for expansion, new cable installations no longer use the direct burial method. Direct burial cables are primarily used for maintenance of existing cable routes.

Flame Retardant Fiber Optic Cables (GYTZA)

GYTZA cables have the same structure as GYTA cables. The difference is that the jacket of GYTA cables is made of polyethylene material, while the cover of the GYTZA cables is made of fireproof material.

GYTZA cables are mainly used in entry segments for central nodes and important convergence nodes. Generally the length of each input cable segment should not be less than 500 metros.

FTTH Fiber Optic Cables

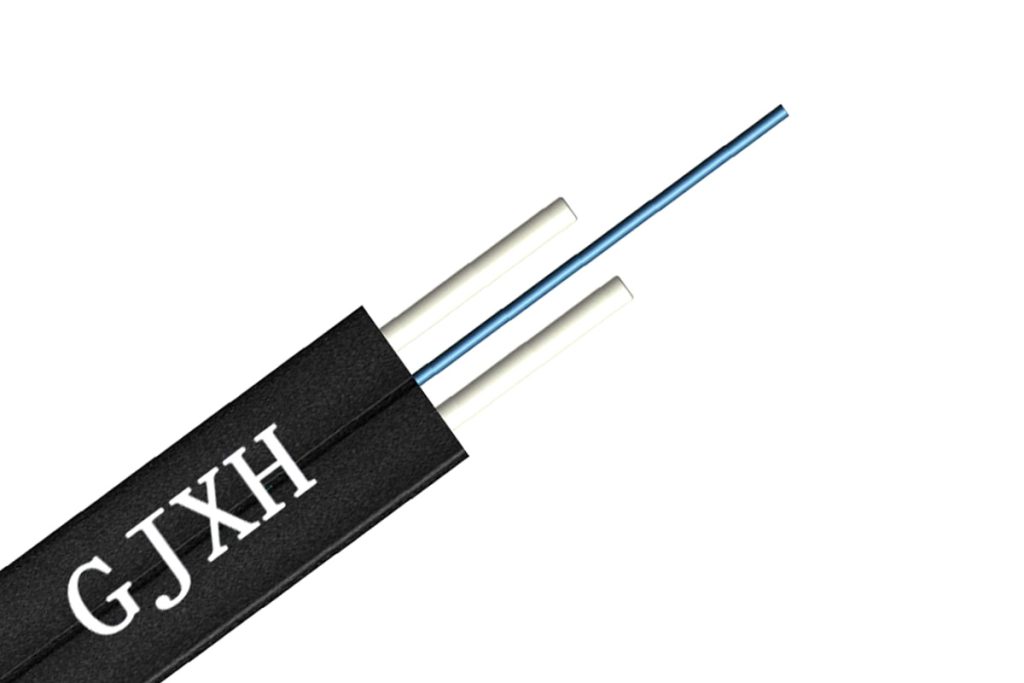

FTTH fiber optic cables are mainly used in FTTH introduction section (from the fiber optic distribution box to the ONT device in the user's home). They are divided into conventional butterfly types (GJXH), self-supporting butterfly type (GJYXFCH), butterfly type with pre-terminated ends, hidden cables and hidden cables with pre-terminated ends.

Conventional Butterfly Introduction Cables (GJXH)

Within the types of FTTH fiber optics, GJXH cables are preferred for their ease of installation in indoor environments. GJXH cables place fiber optics in the center, with two steel wires parallel to the sides as reinforcing elements. And they are coated with a low smoke flame retardant coating. Common GJXH cables have 1 o 2 fibras, with cover dimensions of 2mm on the short axis and 3mm on the long axis, a permissible short-term tensile stress (minimum value) the 200N. And they are suitable to be installed along walls or in pipes, but they are not suitable to be suspended in the air.

Self-Supporting Butterfly Cables (GJYXFCH)

GJYXFCH cables add an element of reinforcement (steel wire or steel rope) to the outside of conventional non-metallic butterfly introduction cables (GJFXH). Common GJYXFCH cables have 1 o 2 fibras, with a permissible tensile stress (minimum value) the 600N, can be suspended in the air for a short distance (less than 50 metros). They are suitable for introduction from the outside to the inside.

Butterfly Cables with Preterminated Ends

Butterfly introductory cables with pre-terminated ends have SC-type insert connectors pre-installed on both ends of a fixed-length GJXH or GJYXFCH cable, thereby reducing the amount of completion work on site during installation.

Hidden Cables (BREAST)

GJIXH cables are similar in structure to conventional butterfly introduction cables.. But the difference is that the core part of GJIXH cables is single fiber hidden fiber optic cable (BREASTFEEDING). GJI cables are essentially tight-fitting optical fibers, consisting of a non-colored G.657 optical fiber covered with a transparent protective layer of 0.9mm diameter. GJI cables are thin, completely transparent.

During the installation, They are usually fixed with glue along building baselines, around door and window frames, resulting in hidden and aesthetic wiring. When GJIXH cables are used for introduction, The inner part can be torn and cut to remove the reinforcing elements and cable jacket, leaving only the GJI cable for installation. Installation of GJI cables is more complex and expensive. It is suitable for scenarios where users require superior aesthetics in interior wiring..

Hidden Cables with Pre-Terminated Ends

Hidden cables with pre-terminated ends have SC type push-in connectors pre-installed on both ends of a fixed-length GJI cable, thereby reducing the amount of completion work on site during installation. When using hidden cables with pre-terminated ends, a pre-terminated cable is cut in half according to the required length. Can be used for two-user indoor installation. The outer part of the user uses a butterfly type cable, and the outer butterfly cable and the inner hidden cable are fused at a suitable position at the entrance.

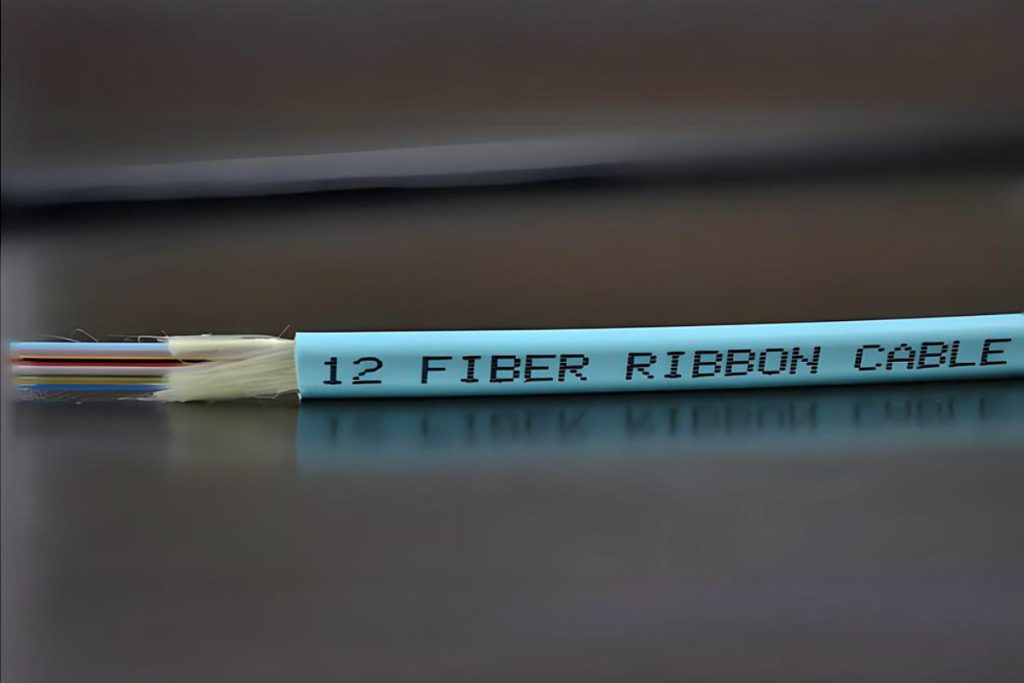

Fiber Optic Ribbon Cables

Fiber optic ribbon consists of 4 a 24 optical fibers arranged in parallel and fixed together by UV curing into a thin, flat ribbon. Cables that use fiber optic ribbons are known as fiber optic ribbon cables.. Fiber optic ribbon cables with a high fiber count can significantly improve cable bonding efficiency when used with fusion machines for ribbon fibers. Although bond loss may be slightly higher than in single fiber cables. Fiber optic ribbon cables are suitable for sections with a large number of fibers in metropolitan networks and cable access networks. Common types of fiber optic ribbon cables have braided structures (TOGETHER) o skeletal structures (SYDGE).

Fiber Optic Ribbon Cables with Braided Structure (TOGETHER)

GYDTA cables have a similar structure to GYTA cables, but the difference is that each loose tube contains several fiber optic ribbons of 4, 6, o 12 fibers instead of loose fibers. GYDTA cables are suitable for duct or overhead installations. An example of specifications for a GYDTA cable with 288 fibers is GYDTA-288B1.3-12F, containing tapes 12 fibras.

Fiber Optic Ribbon Cables with Skeleton Structure (SYDGE)

Skeleton structure fiber optic ribbon cables contain fiber optic ribbons placed in skeleton slots made of high-density polyethylene (HDPE), with a central core composed of a single steel wire or several stranded steel wires. A waterproof tape is wrapped around the skeleton, followed by plastic coated aluminum tape on both sides (APL). And finally, a polyethylene cover is extruded (PE). A tear rope is placed between the aluminum tape and the waterproof tape to make it easier to open the cover..

GYDGA cables are suitable for duct or overhead installations, and the fiber optic ribbons inside usually have 4 o 6 fibras. GYDGA cables are quite rigid. Although they have the same bend radius requirements as common cables, they can be more difficult to manage. An example of specifications for a GYDGA cable con 288 fibras es GYDGA-288B1.3-6F, containing tapes 6 fibras.

Conclusion

In summary, Fiber optic cables have evolved significantly to meet the needs of various communications applications.. From underground installations to overhead lines and indoor environments, Each type of cable has been designed to offer optimal performance in specific conditions. Types of optical fiber must be selected based on requirements such as mechanical resistance, water resistance, ease of installation and signal transmission performance. This ensures that communication networks can be robust, reliable and capable of meeting current and future connectivity demands.