Power cable is the longest and most demanded cable product in power transmission, distribution and other essential electrical transfer lines.

Tubular water trees are water trees developed from insulating screens or conductive screens which are water trees from impurities or other defects in the insulation that develop radially towards the insulating screen and the conductive screen.

Why do we need medium and high voltage cables?

With social progress and economic development, humans are increasingly dependent on electrical energy, the demand for electrical energy is increasing.

Nevertheless, most countries in the world have a problem of unequal distribution of energy and productivity.

Therefore, the construction of large-capacity, long-distance power grids has drawn much attention from the governments of all countries. To reduce line loss in long distance transmission, high voltage transmission technology is required.

China is actively developing transmission and distribution lines of EHV and UHV. Along with the development of EHV transmission technologies, More and more demands are being placed on power cables, which is an important component of the power grid and must withstand the test of high and ultra high voltage.

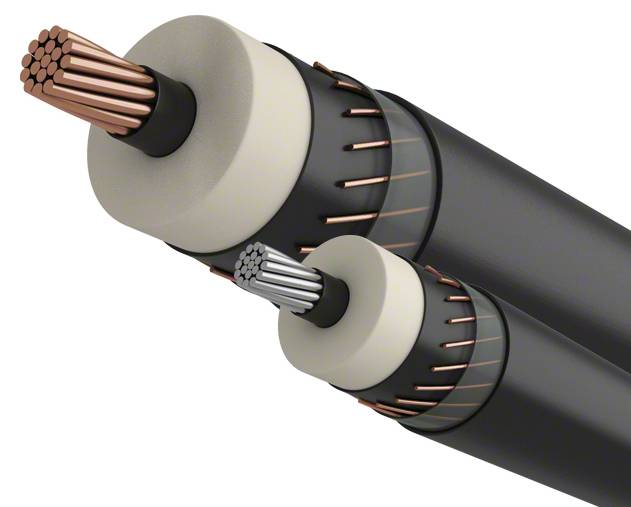

XLPE cable has good electrical performance, large transmission capacity (long-term operating temperature up to 90 °C, instantaneous short-circuit temperature up to 250 °C), light weight, lower production process, Fast production and Short manufacturing cycle, high drop the vertical laying, easy installation and maintenance, and other advantages of simple structure.

It has been favored by users, increasingly popular in the energy sector, its share in the field of high-voltage and high-voltage cables continues to gradually increase Replaces the trend of other types of cables.

The relationship between the voltage, the conductor and XLPE insulation

Currently, the international 220KV and below the main high voltage XLPE cable insulation voltage level, 500KV XLPE insulated cables have also been used in EHV lines.

Long-term operation and experience shows that the aging of the water tree is one of the main factors leading to the deterioration of the XLPE insulation of the XLPE cable..

The DL/T standard 1070-2007 defines a water tree as “the presence of moisture in the insulation, electrical stress and certain triggers, as impurities, bumps, space charges or ions.

When they develop in some microchannels, tube water trees and bowtie water trees appear.

water resistant trees, nevertheless, contain cross-linked polyethylene insulation which can retard the development and growth of the insulation, polymer modification or water tree filling.

Reasonable selection of cleaning guarantee, optimization of processes, etc., the successful development of cable waterproof tree performance.

Waterproof tree crosslinked cable is mainly through the semiconductor material's resistance to water molecules to penetrate, which reduces the depth of water molecules within the insulation.