In the world of electrical installations, Cable protection is vitally important to ensure safe and efficient operation. Preformed rebars are an innovative solution that has gained popularity for its ability to protect cables from a variety of external threats., like vibrations, tightening efforts, abrasion and arcing.

Table of Contents

- Principle of Preformed Truss Rods

- Outstanding Features

- Applications of Preformed Rebar Rods

- conclusions

Principle of Preformed Truss Rods

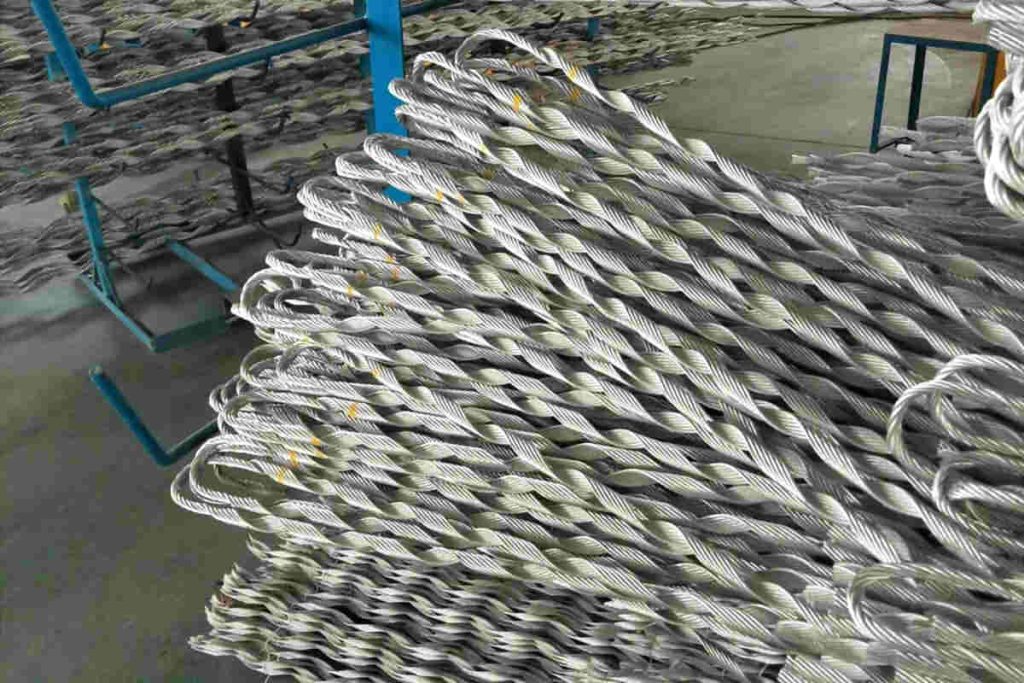

Preformed rebar rods are made by pre-twisting a series of spiral wires from a single strand.. These coiled wires, with a specified inside diameter, are coiled helically to form a tube-shaped cavity.

The resulting spiral is wrapped around the cable to be protected., and under the cable tension, fits tightly to this, providing a secure grip. The higher the cable tension, the tighter the spiral rotation and, but still, the greater the grip on the cable.

Outstanding Features

Preformed reinforcing rods have a number of outstanding features that make them a preferred choice for the protection of electrical cables and conductors in various industrial applications..

Wear and Abrasion Resistance

One of the main advantages of preformed rebar is its ability to resist wear and abrasion.. When power lines are running, especially in power transmission and communications applications, are exposed to external forces that could cause friction and wear. The spiral design of the pre-shaped truss rods ensures a firm and secure grip around the electricity cable, preventing it from slipping and deteriorating due to friction with other elements or nearby surfaces. As a result, cable life is extended and the need for frequent maintenance and replacement is reduced.

Anti-Loosening and Stability

Another important feature of preformed rebar rods is their resistance to loosening.. Due to the elasticity of the spiral design, these rods maintain a tight and constant grip on the cable even under stress and vibration conditions. This prevents unwanted movement of the cable and minimizes the possibility of failures due to slippage or accidental disconnection.. The stability provided by preformed rebar is essential in environments where cable integrity is crucial to the safe and reliable operation of the electrical or communications system..

Corrosion Resistance

The antioxidant treatment which is applied to preformed reinforcing bars makes them highly resistant to corrosion. This is especially important in areas where cables are exposed to humid environments., corrosive or with high relative humidity. Corrosion can weaken the structure of the cable and affect its ability to transmit signals or power efficiently and safely.. When using preformed rebar, cable integrity is protected over time, which translates into greater durability and reliability of the system.

Ease of Installation

Preformed rebar rods are extremely easy to install. They do not require complicated tools or specialized personnel for assembly. Just using your bare hands, one person can complete the installation quickly. This ease of installation is especially valuable in situations where time and efficiency are critical., as in maintenance tasks, repairs and in infrastructure projects that require rapid start-up.

Versatility and Compatibility

Preformed rebar rods are compatible with a wide variety of accessories and cables, which makes them extremely versatile. Can be adapted to various applications and systems, from power cables to fiber optic cables for communications. Their flexible and adaptable design makes them a practical and cost-effective solution for a wide range of industries and projects..

Applications of Preformed Rebar Rods

Preformed Truss Rods, due to its unique characteristics and versatility, have found wide applications in various industries and sectors. Next, We detail some of the key areas where these innovative solutions have proven their worth.:

Power Transmission and Distribution

In the electric power transmission and distribution sector, preformed reinforcing rods play a fundamental role in the protection of overhead conductors. Cables used in high voltage power lines are exposed to harsh environmental conditions, like strong winds, rain, and temperature changes. Besides, vibration caused by charging and discharging electricity, as well as by external factors such as the movement of nearby trees, can damage cables over time.

Preformed rebar bars offer an effective solution to mitigate these risks.. They are applied in short sections of conductors, forming a protective layer that prevents arcing and abrasion. This helps maintain cable integrity and prolongs cable life., ensuring a reliable and safe electrical supply.

Fiber Optic Communications

With the exponential growth of fiber optic communications, fiber cable protection has become crucial. Truss rods preformed as a type of fiber optic fittings have become a popular choice for safeguarding these sensitive cables that carry data at impressive speeds.

In telecommunication network applications, preformed rebar ribs provide an additional barrier against the harmful effects of the outside environment, such as humidity, mechanical pressure and rodents that could damage the cables. The protection of these fiber optic cables is essential to guarantee the quality and reliability of data transmission., both in long-distance telecommunication networks and in local networks.

Electrification of Railway Lines

In the field of transport, electrified railway lines use high voltage cables to supply power to trains. These cables are subjected to constant stresses and vibrations due to the movement of the trains along the track.. Besides, exposure to extreme weather conditions, like the rain and the wind, it can also affect the integrity of the cables.

Preformed rebar rods provide vital protection in this application. By wrapping rods around high tension wires, a layer is formed that protects them from vibrations and prevents material fatigue. This protection guarantees the durability and reliability of the cables., which translates into a safe and efficient rail service.

Construction and Agriculture

In construction and agricultural environments, electrical cables are often exposed to adverse conditions. Whether on construction sites, farms or outdoor facilities, these cables are subject to wear, corrosion and mechanical damage.

Preformed reinforcing rods are an effective solution to protect cables in these applications.. Its ability to resist corrosion and wear, along with its ease of installation, makes them a convenient and effective choice for keeping electrical cables safe and operational in these challenging conditions.

conclusions

Preformed reinforcing rods are an ingenious advance in the field of electrical installations. Its simple but effective design, along with its prominent features, make them a preferred choice for protecting electrical cables and conductors in various applications industrial.

From power transmission to fiber optic communications, these rods offer reliable and long-lasting protection, ensuring safe and efficient operation of electrical systems.

with a promising future, preformed rebar will continue to play a critical role in electrical and communications infrastructure around the world.