During the rainy season, fiber optic cables laid outdoors often face the risk of moisture and water ingress. If water enters the fiber optic internet cable, will it affect signal transmission? How can you prevent the ingress of water into fiber optic cables??

Table of Contents

Are Fiber Optic Cables Waterproof??

What Are The Dangers of Moisture and Water Entry into Fiber Optic Internet Cable?

Does Water in Fiber Optic Cable Affect Signal Transmission?

– Impact on other fiber optic equipment

– What to do if water enters a fiber optic box?

What Measures Can Be Taken to Prevent the Ingress of Water into Fiber Optic Cables?

Waterproofing of Submarine Fiber Optic Cables

Are Fiber Optic Cables Waterproof??

From a structural perspective, the internal optical fibers are filled with oil paste and are protected by a waterproof outer layer and a plastic protection layer. Therefore, the amount of water that can penetrate optical fibers is usually very limited and, in general, does not affect its normal operation. Nevertheless, being exposed to humid environments for a long time can also be detrimental to fiber optic cables.

What Are The Dangers of Moisture and Water Entry into Fiber Optic Internet Cable?

After the fiber optic cables get wet, its physical characteristics, as the protection layer and oil paste, can change. Especially, the coating layer of optical fibers becomes very brittle after being wet, which severely reduces your stamina. Prolonged exposure to moisture can cause optical fibers to break with just a light touch.. Besides, Moisture-affected fiber optic cable insulation can also affect its effectiveness in preventing lightning strikes..

Long-term water ingress into the outdoor fiber optic cables can increase fiber loss, especially at the wavelength of 1,55 µm. This is because fiber optics are made up of interconnected glass silica tetrahedrons.. In a humid environment, the glass surface adsorbs the water vapor and a reaction of hydrolysis. This causes the silicon-oxygen bonds to break and the unbridged oxygens to become bridged oxygens., resulting in continuously expanding glass cracks.

Many people think that fiber optic internet cable is glass and therefore, waterproof. But this is not true. The diameter of glass in fiber optics is only 0,125 mm, about the thickness of a hair. If there are cracks, will have an even greater impact on your normal functioning.

Besides, in a cold environment, water entering fiber optic cables will freeze and expand. This will also damage the optical fibers.

Does Water in Fiber Optic Cable Affect Signal Transmission?

Since fiber optics are not conductive, the mere ingress of water into a fiber optic cable will not affect signal transmission. Nevertheless, prolonged contact of the optical fiber with water can affect the strength of the optical transmission signal. Once a significant level of affectation is reached, may cause signal interruptions. In general, brief periods of immersion caused by rain do not have a significant impact on signal transmission.

If there are fiber optic splices, especially those that are not merged (such as adapter connectors between fiber hops), water absorption will cause significant light intensity loss, which will seriously affect the signal transmission. In the case of fused splices, removing the outer coating of the fiber can have a negative effect, but not that significant.

Impact on other fiber optic equipment

severe impact:

Fiber Optic Splice Boxes, distribution boxes, terminal boxes.

moderate impact:

Aerial fiber optic boxes, underground fiber optic splice boxes.

What to do if water enters a fiber optic box?

If water enters a fiber optic box, you must first remove the outer casing from the box and blot the water with clean paper. Then, you can use a hair dryer at a safe distance to dry the interior. Nevertheless, the sealability of fiber optic splice box will decrease after drying. If possible, it is recommended to replace the fiber optic box with a new one.

What Measures Can Be Taken to Prevent the Ingress of Water into Fiber Optic Cables?

- Before installing fiber optic cables, a waterproofing layer can be applied to the areas that the cables will pass through and buried there, to prevent rain from penetrating and causing connection failure.

- In places where fiber optic cables are installed, highly elastic waterproof rubber tapes can be placed, to ensure water resistance even during the strongest storms.

- Waterproof materials can be used to seal fiber optic cable splices., avoiding the ingress of water that could cause equipment failure.

- Choose high quality fiber optic cables with water resistance guarantee.

- Cover fiber optic cables with a layer of waterproof material or cloth to protect them from rain.

- Carry out regular inspections of fiber optic cables to prevent possible failures and ensure their correct operation.

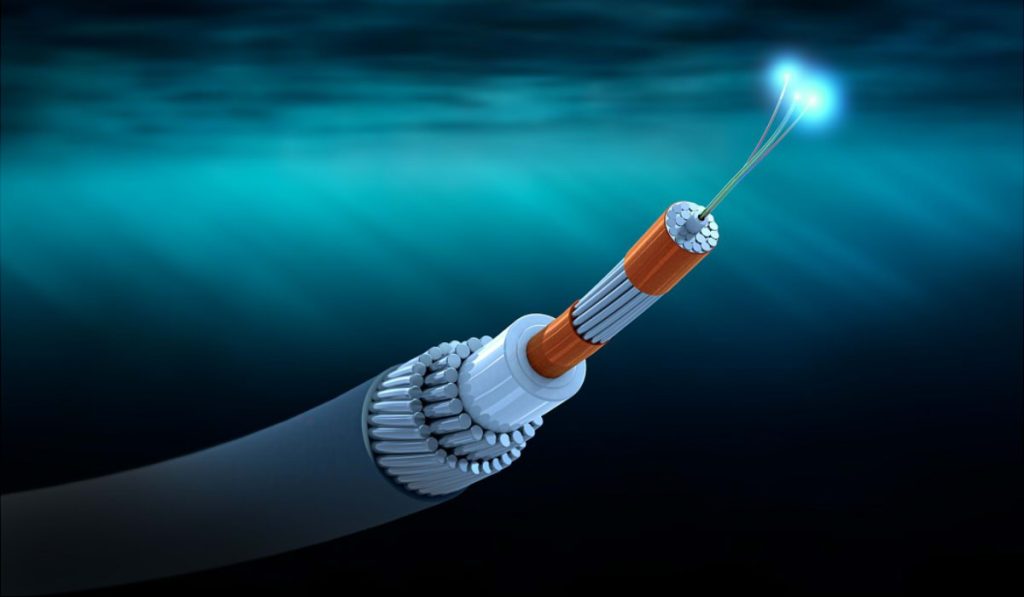

Waterproofing of Submarine Fiber Optic Cables

Waterproofing measures for submarine cables are more complex than those for land cables due to the harsh marine environment. Submarine cables are exposed to saltwater corrosion and hydrogen diffusion, which can reduce its resistance and increase light loss.

The basic structure of a submarine optical fiber includes a layer of polyethylene, polyester resin or asphalt, a layer of steel wire, a layer of waterproof aluminum, a layer of polycarbonate, a copper or aluminum pipe, cera, alkane and a multilayer coated fiber optic bundle.

The waterproofing measures of the submarine internet cables include radial and longitudinal measurements. Radial measurements involve wrapping the outside of the fiber optic with waterproof tape and adding a waterproof metal layer. Longitudinal measurements involve the addition of impervious materials in the internal structure of the cable to block water diffusion channels in the cable core..