CPE cable refers to a cable with a chlorinated polyethylene sheath.. Due to the advantages of heat resistance, oil, ozone, aging, etc., CPE cable has been widely used in various industries.

Table of Contents

CPE Performance Characteristics

– CPE chlorination degree

Advantages of CPE Cable

– Heat resistance

– color processing

– irradiation processing

– Price of CPE Cables

CPE Cables in Low Voltage Applications

CPE Cable Insights

CPE Performance Characteristics

Chlorinated polyethylene (CPE o CM) is a synthetic polymeric material prepared by modifying polyethylene by chlorination. Due to its saturated and irregular linear molecular structure, has excellent flexibility, resistance to thermal aging and ozonolysis. Thanks to the considerable proportion of chlorine in its molecular structure, CPE also has good oil resistance, to chemicals and ignition.

Due to the different production techniques and the variety of polyethylenes used as raw material, CPE can have great variability in its properties. The main factors that affect its properties are the chlorine content, chlorine distribution and crystallinity. The type and properties of the raw material polyethylene determine the processing and the physical and mechanical properties of the CPE.

CPE chlorination degree

The degree of chlorination also has a large impact on the CPE.. An increase in chlorine content can improve oil resistance, the air permeability and flame retardant property of CPE cable. Secondly, a decrease in chlorine content can improve the cold resistance and rebound capacity of the CPE product.

Different distribution and crystallinity of chlorine lead to different physical and processing properties of CPE. When the chlorine content is less than 15%, it's a plastic. And when the chlorine content is in the range of 16-24%, is an elastic thermoplastic. When the chlorine content is in the range of 25-48%, it is an elastic rubber. Besides, when the chlorine content is in the range of 49-58%, is a semi-elastic polymer similar to leather. When the chlorine content reaches 73%, becomes a brittle resin.

CPE made of low-density polyethylene HDPE has better high-temperature thermal aging performance than CPE made of high-density polyethylene. The typical density range of the produced CPE is 0.93-0.96g/cm3. Its average molecular weight is 5-25 millions. Its melt index is in the range of 0.01-2.0g/10min.

Advantages of CPE Cable

CPE as a cable material has excellent resistance to flame and oils, good physical-mechanical properties, resistance to thermal aging and ozonation, and good mix compatibility.

Heat resistance

Previously, cables insulated or protected with natural rubber or styrene butyl had a maximum working temperature of only 60 ℃ o 65 ℃. While, in the process of use, Chloroprene rubber often has quality problems such as burning and sticking, which seriously affects the technological level of rubber cables. The CPE has a maximum long-term working temperature of 90 °C. If the formula is correct, the maximum working temperature of the CPE rubber cables can reach the 105 °C.

color processing

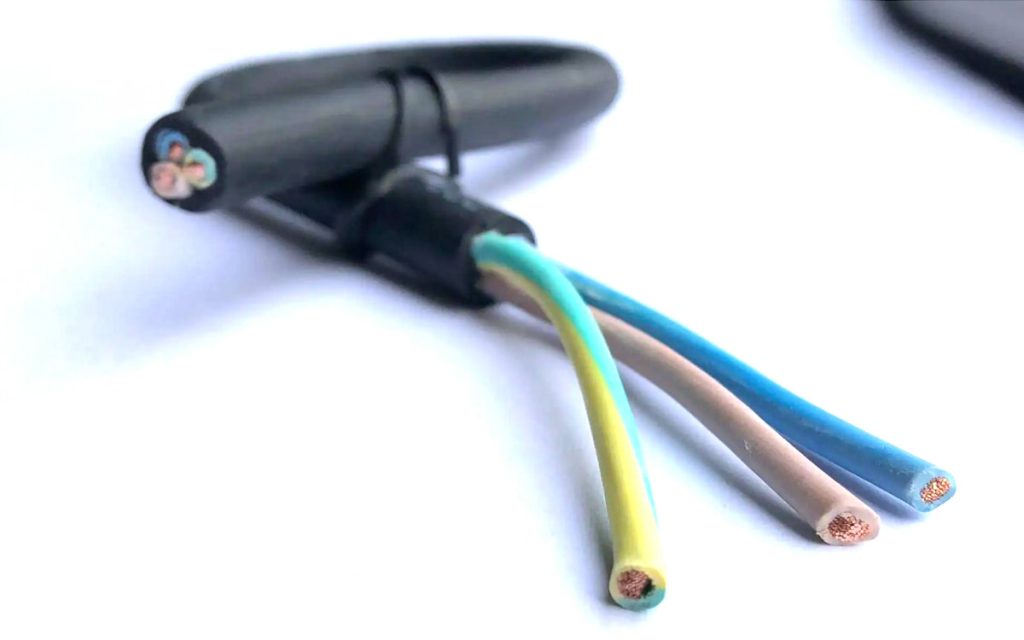

Traditional rubbers such as natural rubber, butyl styrene, Chloroprene and Butadiene Nitrile are difficult to make into brightly colored or pure white products due to their yellowing. Instead, CPE is snow white, so it can be manufactured into bright colored products according to customer needs, both as insulation and protection material for cables.

irradiation processing

After extrusion with a rubber extruder, CPE blends can be thermally crosslinked in a high temperature environment or crosslinked by electron irradiation at room temperature. Instead, conventional neoprene cannot be crosslinked by electron irradiation studies.

Price of CPE Cables

When comparing the cost of CPE blended rubber and CR blended rubber (chlorinated rubber), it can be found that the CPE is of 1,700 a 2,000 dollars per ton cheaper than the same content of CR. Considering that chrome rubber is prone to burning and produces a higher proportion of waste, the cost of CPE rubber is much lower than that of chrome plating. NBR and CSM materials are also more expensive than CPE. Therefore, the price of CPE rubber cable is relatively cheap.

CPE Cables in Low Voltage Applications

In low voltage applications, CPE cables are mainly divided into two categories based on their use: cables for construction and cables for electrical equipment. Regarding construction cables, since the decade of 1970, natural rubber insulating cables have been completely replaced by pvc cables. The situation in electrical equipment circuits is similar to that of construction circuits., where natural rubber originally dominated, but after the decade of 1970, most natural rubber cables have been replaced by PVC cables due to the lower cost of the latter.

Nevertheless, the exclusive use of PVC cables is unreasonable. Compared to plastic cables, rubber cables have advantages such as flexibility, heat resistance and be more friendly to the environment. Because CPE has many advantages that other synthetic rubbers do not., CPE cables can be widely used in the manufacture of power cables for home and other electrical equipment.

Besides, during production, storage and transportation of CPE cables, no problems with toxic and volatile monomers and solvents, as well as other difficult problems to solve. The production process of CPE cables does not contaminate the copper core. Therefore, CPE cables can completely replace the different colored insulated cables and sheaths of 65℃ low voltage cables, 85℃, 90℃. CPE adhesive can also be used as a material for cable products, like locomotive cables, submersible pump cables, ship cables, motor cables, among others.

CPE Cable Insights

CPE wire, as a special synthetic rubber, It has already been widely used in many fields. Its use and function continue to expand and improve.. Blending CPE with other polymeric materials to develop new engineering plastic alloys has become one of the hot topics in materials research.. Currently, CPE cables are steadily developing towards specialized high-tech application fields.