The silicone wire uses silicone rubber as an insulating layer.. This material can resist high temperatures and has great flexibility.. Due to its stability in electrical performance and outstanding resistance to aging, this wire is widely used in the fields of metallurgy, Energy, electronics and aviation.

Silicone rubber is a liquid rubber vulcanized at room temperature, single component. Once exposed to air, los silane monomers containing condense, forming a network structure. The system is crosslinked and cannot be melted or dissolved. This structure allows the material to be elastic and become rubbery when gluing objects. Its thermal conductivity is slightly higher than that of normal rubber and, once cured, it is difficult to separate joined objects.

Characteristics and Applications of Silicone Cables

Silicone cables are suitable for mobile or fixed power lines with a rated voltage of AC 450/750V or less., or signal transmission lines. Los silicone rubber cables have good thermal stability and can maintain good electrical properties and flexibility in high-temperature environments, low temperature and corrosive.

These rubber cables made of this material are suitable for use in industries such as metallurgy, energy, the petrochemical, electronics and automobile manufacturing, that have special requirements for mobility and resistance to high temperatures. Besides, silicone cables are also frequently used in areas such as rail transport, the medical industry, the nuclear energy, the construction, household appliances, electric heating and heavy industry.

Heat Resistance of Silicone Wires

In theory, silicone material is much more resistant to heat in the air than organic rubber. At a temperature of 150℃, the physical and mechanical resistance of the silicone wire is practically not affected. A 200℃, silicone wire can work continuously for more than 10.000 hours. Nevertheless, at a temperature of 380℃, the silicone wire can only be used for a short period of time.

The heat resistance of silicone material is related to the type of raw rubber, vinyl content (crosslink density), the type of heat resistant additive and the amount of silicone used. Besides, the pH and amount of water of the mixed rubber also affect the heat resistance of the silicone wire. Therefore, los rubber cable manufacturers should pay special attention to the selection of the polymerization catalyst, the neutralization of the residual catalyst after the reaction, the choice of fillers such as carbon black and silicone structure regulators during rubber production.

Silicone cables in Electric Vehicles

In the field of new energy electric vehicles, the silicone high voltage cable can be used to connect high voltage battery, the electric control unit and the electric motor. It can also be used as an internal connection cable for high-voltage equipment such as air conditioning and auxiliary heating., or as internal battery connection cable.

Currently, Insulating materials for vehicle power cables on the market include cross-linked polyolefin and thermoplastic elastomer. Crosslinked polyolefin can withstand a maximum temperature of 150°C, but the cables made of this material are relatively rigid and not easy to install in the limited space of the vehicle. Besides, the irradiation crosslinking process is complex and not suitable for cables with large cross-sections. thermoplastic elastomer, on the other hand, has a maximum temperature resistance of 125°C, which limits its use in high power power cables. Besides, there is a risk of cable cracking in the long term. Therefore, in the field of new energy electric vehicles, silicone wire is the best option.

Characteristics of Use of the Silicone Cable

AC rated voltage: U0/U 450/750KV

maximum working temperature: 200℃

Minimum working ambient temperature: -60℃(fixed installation), -20℃(mobile installation)

Installation of the cable at temperature: >-20℃

Minimum allowable bend radius of the cable: 6 times the outside diameter (for unarmoured cables)

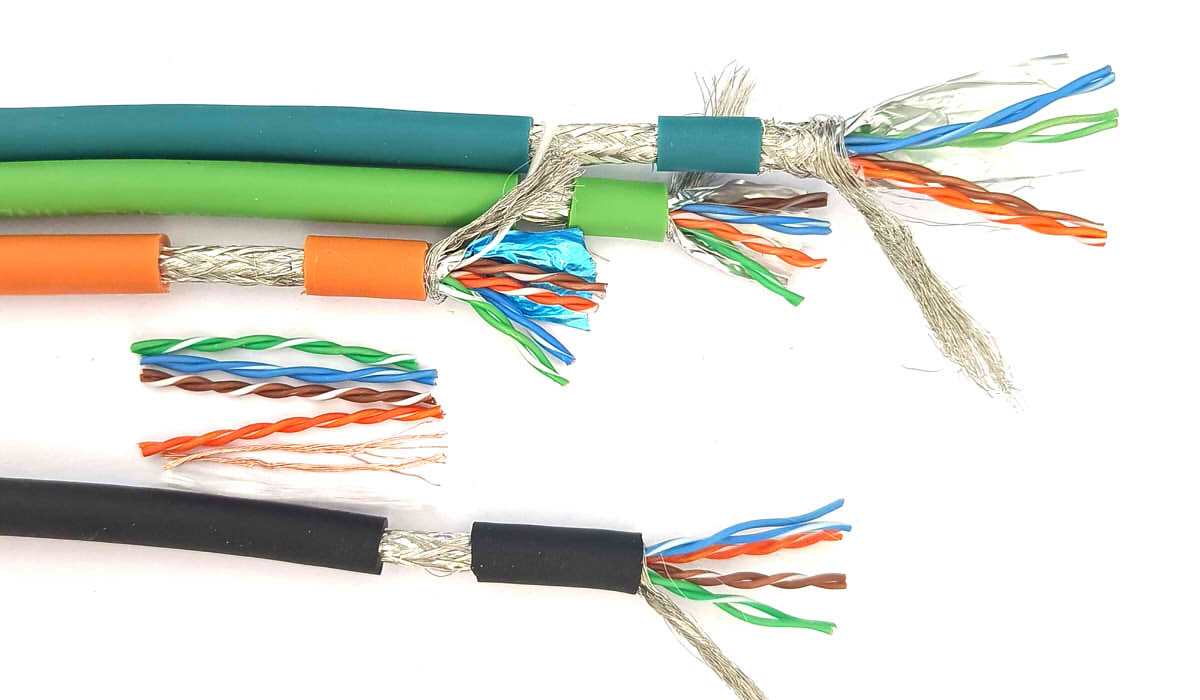

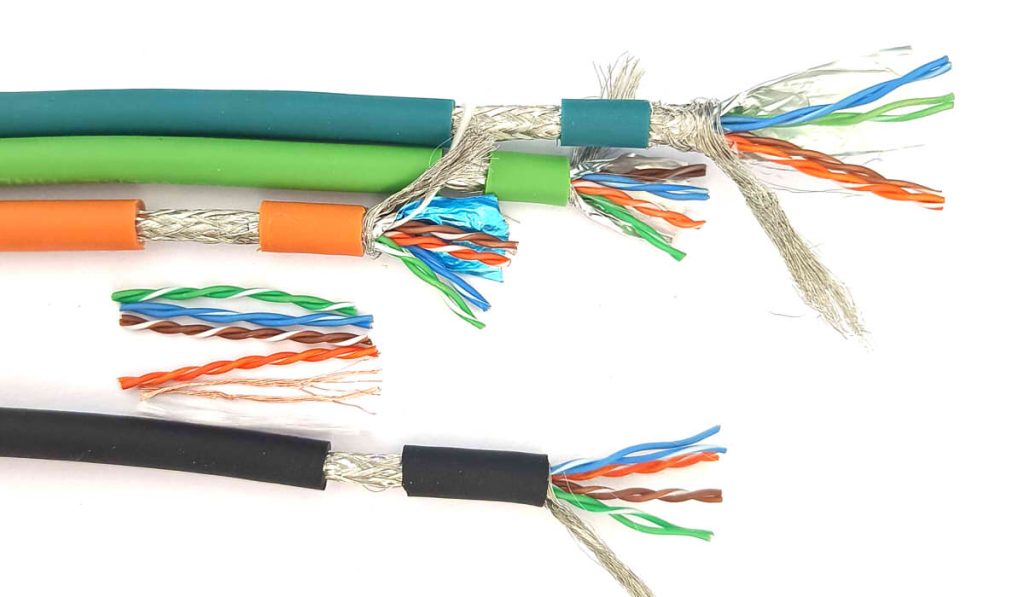

What Are The Differences Between Silicone Rubber Cables And Normal Cables?

- The coating of silicone cables is different from other common cables. Rubber coated silicone wire has good resistance to water and wear. It can be used in humid and adverse environments, while ordinary cables cannot.

- The surface of the silicone cable is very thick and resistant, so it reduces the loss during use and has a longer lifespan.

- The price of silicone wire is higher, so it is not favorable for general use. Due to the high investment cost, the initial cost is also high. Nevertheless, It is type of cables has fewer failures during use, does not require frequent maintenance and has characteristics such as resistance to aging, wear resistance, oil resistance and fire resistance, which makes it more suitable for use in some specific situations.

Resume

Silicone cables are an excellent option for those who need flexible and resistant electrical cables.. One of its main advantages is its high temperature resistance., making them ideal for use in environments where high heat resistance capabilities are required. Besides, are resistant to moisture and water, so they are also useful in outdoor applications and in humid environments. Silicone cables are an excellent option for those who need flexible and resistant electrical cables in environments with high temperatures and/or humidity.. Although they are a little more expensive than conventional cables, Their durability and long life make them a worthwhile investment in the long run..