With the gradual increase in environmental awareness, the demand for new energy vehicles is also growing.

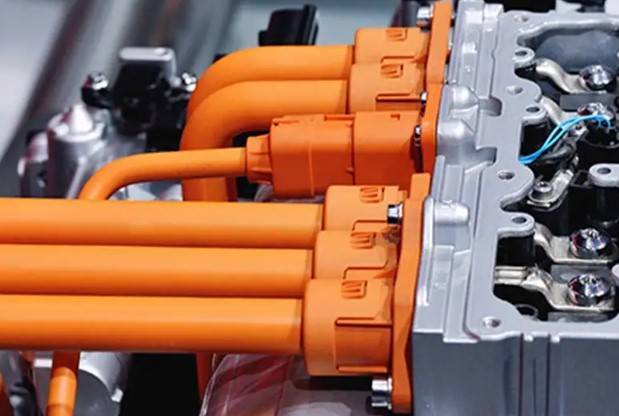

High-voltage cables for new energy vehicles are usually organized by cables, connectors, protection materials (insulating tubes, prepared tubes), mounting brackets (the coilable straps), sealing rings, adhesive tapes, heat shrink tubing, hang tags, etc.

Structure of high voltage cables for vehicles

High voltage cables are made up of conductors, isolation, deck, appantallamiento, foil, lining tape, filling, etc.

Conductor: composed of a soft annealed copper conductor or a tinned copper conductor.

hard copper wire: cold stretch processing, with high tensile strength. It is suitable for aerial cables for electricity, distribution lines and construction lines.

soft copper wire: Manufactured from heated hard copper wire to eliminate residual stresses caused by cold working. It is flexible and foldable, and has a high electrical conductivity.

It is used to make conductors for communication and power cables., electrical machinery and various household appliances.

Tinned copper wire: the surface of the copper wire is tin plated to increase solderability. It also protects the copper conductors from erosion when they are extruded from the PVC or rubber insulation.

Besides, prevents insulation aging. Tinned copper wire is generally used for high voltage cables with a temperature resistance of 150°C and above..

Currently, most of the drivers in the new energy vehicle industry are made of oxygen free copper wire. It is copper wire with an oxygen content of 0,001% or less and a very high purity, with a copper content of 99,99%. Not subject to oxygen embrittlement.

The flexibility of high voltage cables is largely determined by the design of the conductor. Thus, high voltage cables use special conductors with a large number of very small diameter monofilaments.

Monofilaments are first bundled together and then concentrically twisted to form the flexible conductor needed for high-voltage cables.. The advantage of stranded conductors is that they have greater resistance to bending..

Materials of insulation and cladding

The most widely used materials in industry today are low-smoke, halogen-free, cross-linked polyolefins., silicone rubber materials, the materials fluoroplastics, etc.

thermoplastic materials: these materials can quickly soften or liquefy when heated. And they can soften again when heated after molding, like PVC, TPE, etc.

Thermostable plastics: this material cannot be softened and shaped after curing and reheating, like XLTPE, XLTO, etc.

Crosslinking is the transformation of a polymer from a thermoplastic material with a chain structure to a thermosetting material with a three-dimensional mesh structure..

Thermoplastic material melts and flows when heated, and the process of insulating or coating the cable takes advantage of this characteristic.

This information is provided by ZMS Cable Group, a professional manufacturer of various cables and related accessories. If you have any questions, Contact us.