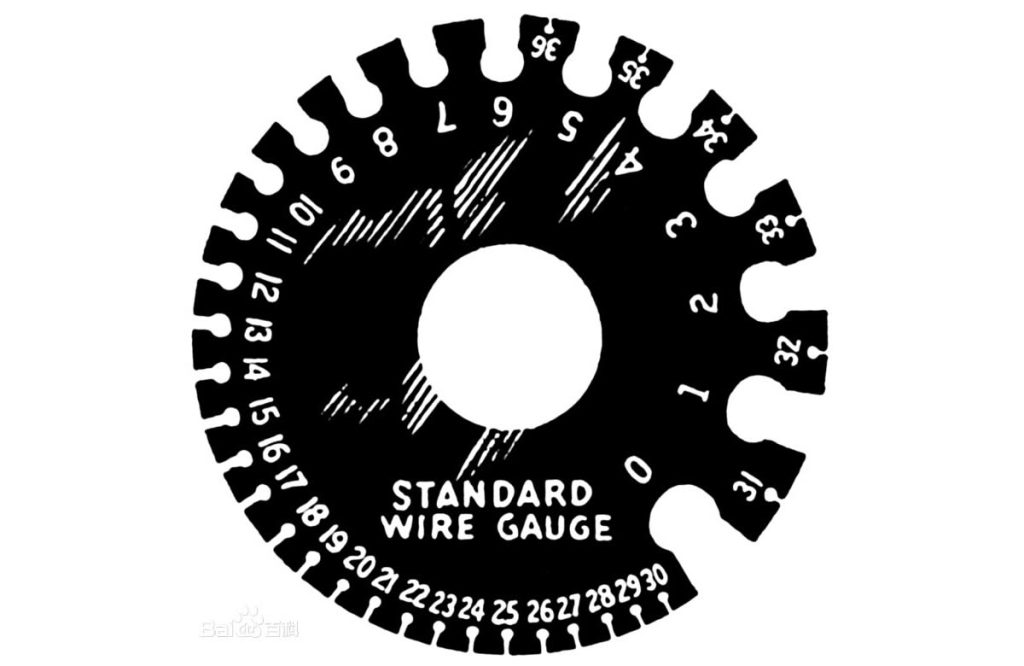

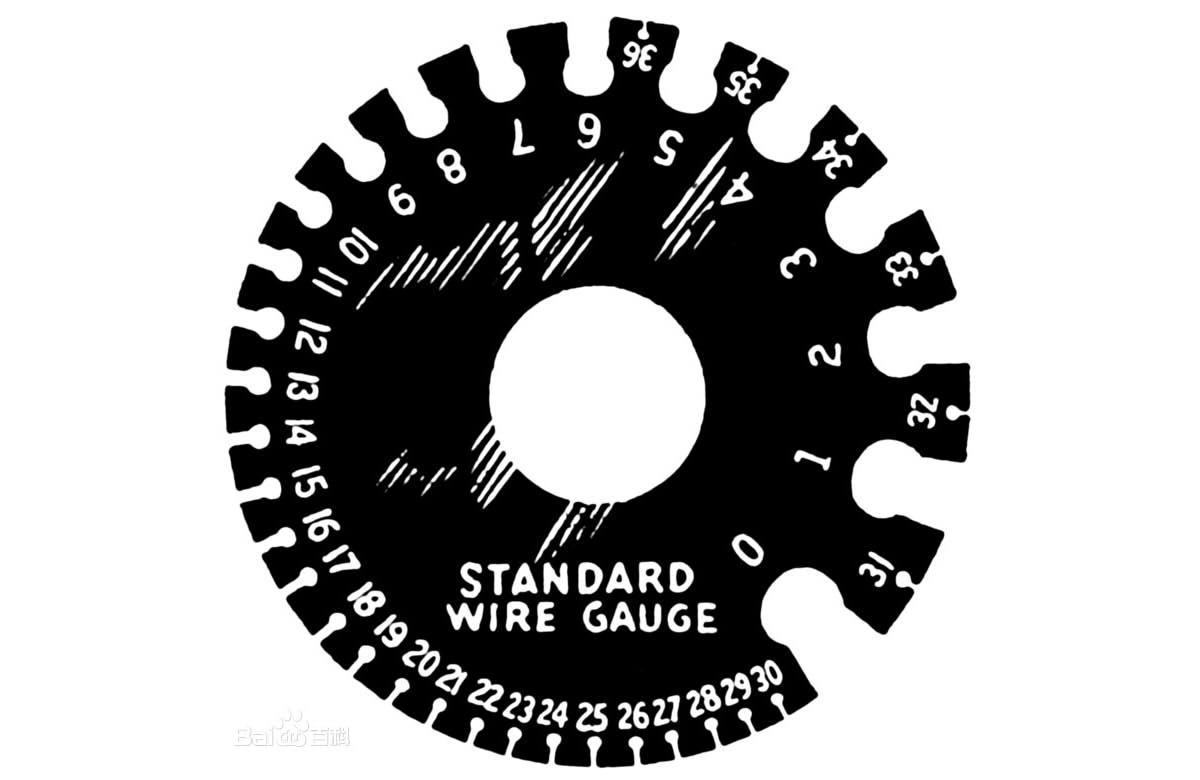

AWG (American wire gauge) is a standard for distinguishing wire diameters and is also known as Brown wire gauge & Sharpe. This standard system of electrical wire gauges is used in the United States.. from 1857.

Table of Contents

- Wire Gauge AWG Comparison Chart

- Application of Different Gauges of Electric Cables

- Current in Copper Cables of Different Diameters

- Current Comparison Method for Copper and Aluminum Cables

- Cable Diameter Calculation Formula

- Formula to Calculate Cable Cross Section

The value in front of AWG (for example, 24AWG, 26AWG) indicates the number of holes through which the cable has to pass before forming its final diameter. The higher the value, the greater the degree of hole through which the cable passes and the smaller its diameter.

In general, los single conductor cables are calibrated based on their diameter, while stranded wires are sized based on their cross section. The larger the cross section, the more current the wire can carry, the greater the distance it can travel.

A common rule for the AWG standard: For every increase in 6 in wire gauge, the diameter of the cable is doubled. For every increase in 3 in the gauge of a wire, the cross sectional area is doubled.

Thicker conductors have higher physical strength and lower resistance. Nevertheless, the thicker the wire, more material is needed to make it. This makes it heavier, more difficult to install and more expensive. The smaller the diameter of the cable, Less expensive and less complex to install.

The challenge in the cable design is to achieve the maximum capacity of the conductor with the smallest possible diameter at the required voltage and frequency.

Wire Gauge AWG Comparison Chart

| AWG | External diameter (mm) | Cross section (mm2) | Endurance (Ohm/km) | AWG | External diameter (mm) | Cross section (mm2) | Endurance (Ohm/km) |

| 4/0 | 11.68 | 107.22 | 0.17 | 22 | 0.643 | 0.3247 | 54.3 |

| 3/0 | 10.40 | 85.01 | 0.21 | 23 | 0.574 | 0.2588 | 66.8 |

| 2/0 | 9.27 | 67.43 | 0.26 | 24 | 0.511 | 0.2047 | 89.4 |

| 1/0 | 8.25 | 53.49 | 0.33 | 25 | 0.44 | 0.1624 | 106 |

| 1 | 7.35 | 42.41 | 0.42 | 26 | 0.404 | 0.1281 | 143 |

| 2 | 6.54 | 33.62 | 0.53 | 27 | 0.361 | 0.1021 | 168 |

| 3 | 5.83 | 26.67 | 0.66 | 28 | 0.32 | 0.0804 | 227 |

| 4 | 5.19 | 21.15 | 0.84 | 29 | 0.287 | 0.0647 | 289 |

| 5 | 4.62 | 16.77 | 1.06 | 30 | 0.254 | 0.0507 | 361 |

| 6 | 4.11 | 13.30 | 1.33 | 31 | 0.226 | 0.0401 | 430 |

| 7 | 3.67 | 10.55 | 1.68 | 32 | 0.203 | 0.0316 | 583 |

| 8 | 3.26 | 8.37 | 2.11 | 33 | 0.18 | 0.0255 | 944 |

| 9 | 2.91 | 6.63 | 2.67 | 34 | 0.16 | 0.0201 | 956 |

| 10 | 2.59 | 5.26 | 3.36 | 35 | 0.142 | 0.0169 | 1,200 |

| 11 | 2.30 | 4.17 | 4.24 | 36 | 0.127 | 0.0127 | 1,530 |

| 12 | 2.05 | 3.332 | 5.31 | 37 | 0.114 | 0.0098 | 1,788 |

| 13 | 1.82 | 2.627 | 6.69 | 38 | 0.102 | 0.0081 | 2,400 |

| 14 | 1.63 | 2.075 | 8.45 | 39 | 0.089 | 0.0062 | 2,740 |

| 15 | 1.45 | 1.646 | 10.6 | 40 | 0.079 | 0.0049 | 4,080 |

| 16 | 1.29 | 1.318 | 13.5 | 41 | 0.071 | 0.0040 | 4,264 |

| 17 | 1.15 | 1.026 | 16.3 | 42 | 0.064 | 0.0032 | 6,300 |

| 18 | 1.02 | 0.8107 | 21.4 | 43 | 0.056 | 0.0025 | 6,936 |

| 19 | 0.912 | 0.5667 | 26.9 | 44 | 0.051 | 0.0020 | 9,180 |

| 20 | 0.813 | 0.5189 | 33.9 | 45 | 0.046 | 0.0016 | 10,200 |

| 21 | 0.724 | 0.4116 | 42.7 | 46 | 0.041 | 0.0013 | 16,300 |

Application of Different Gauges of Electric Cables

The most common electrical wire gauges according to the AWG standard are the following:

Cable calibre 20 AWG: It is used in applications that require low currents, as control circuits, signaling and communications equipment.

Cable calibre 18 AWG: It is suitable for low power applications, such as lighting and alarm systems.

Cable calibre 16 AWG: Used in applications that require more current, such as sound systems and small power tools.

Cable calibre 14 AWG: It is suitable for most residential applications, such as power sockets and lighting.

Cable calibre 12 AWG: Used in applications that require higher current, such as household appliances and heating systems.

Cable calibre 10 AWG: It is suitable for applications that require even higher current, such as air conditioning systems and electric motors.

Cable calibre 8 AWG: Used in high current applications, such as powering large electric motors and high power lighting systems.

Cable calibre 6 AWG: It is suitable for applications that require a very high current, as the main power systems of a house.

Cable calibre 4 AWG: Used in high current applications, such as feeding large industrial facilities.

Current in Copper Cables of Different Diameters

| wire diameter (mm2) | safe load capacity (A) |

| 1 | 17 |

| 1.5 | 21 |

| 2.5 | 28 |

| 4 | 35 |

| 6 | 48 |

| 10 | 65 |

| 16 | 91 |

| 25 | 120 |

Current Comparison Method for Copper and Aluminum Cables

2.5 mm2 Copper wire per 4 mm2 Aluminum wire

4 mm2 Copper wire per 6 mm2 Aluminum wire

6 mm2 Copper wire by 10 mm2 Aluminum wire

2.5 mm2 Copper wire = [4 mm2 Aluminum wire x 5] 20 Amps

4 mm2 Copper wire = [6 mm2 Aluminum wire x 5] 30 Amps

6 mm2 Copper wire = [10 mm2 Aluminum wire x 5] 50 Amps

Cable Diameter Calculation Formula

wire square (mm2) = circumference (3.14) x Square of the radius of the wire (mm)

wire square = Circumference (3.14) x Square of wire diameter / 4

If the cable is multiconductor, is the sum of the cross-sectional areas of each conductor.

Formula to Calculate Cable Cross Section

0.7854 × Square of the radius of the wire (mm) × Number of threads

For example, 48 threads (0,2 mm radius per wire) 1.5mm2 wire: 0.785 × (0.2 × 0.2) × 48 = 1.5 mm2

Is the smaller the wire gauge the better?

When buying cables, if a cable with a small diameter is purchased, its carrying capacity is low. The high power used can easily overload it, thus burning the cable or electrical equipment. So, is it a good idea to buy only thicker diameter cables? In fact, there's no need. The thicker the wire, more expensive it will be.

If you are unsure of the wire gauge you need for your application, Contact us. ZMS cable technicians will offer you a suitable cable selection solution.

3 thoughts on “Gauge of Electrical Cables according to AWG Standard”

Comments are closed.