Submarine communication cables are wires wrapped in insulating material. They are placed at the bottom of the sea to allow the transmission of telecommunications between countries.

The first submarine communication cables provided telegraphic communications. Later, telephone and Internet communications were introduced.. The modern fiber cable also uses fiber optic technology, so it is called submarine fiber optic cable.

How are submarine optical fibers placed??

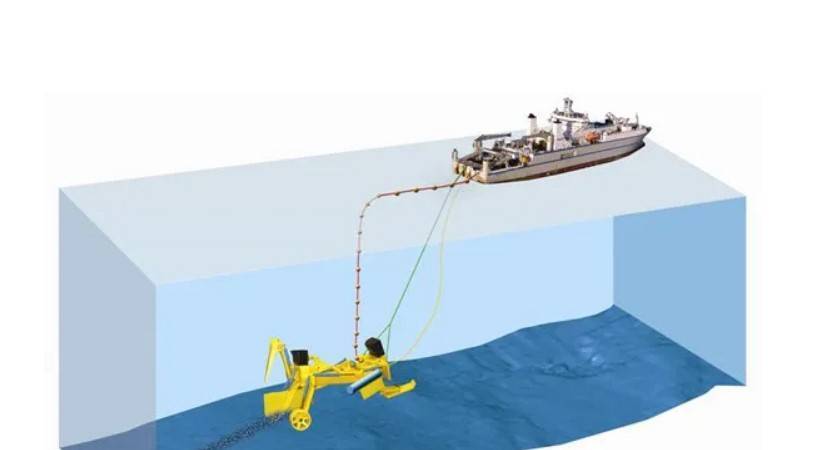

The laying of submarine fiber optic cables is carried out by means of a boat. They are placed on the cable-laying vessel and then sink to the seafloor while the ship is in motion.

Specific, cable laying mainly includes three stages: study and cleaning of cable routing, laying of the same and protection of the burial.

Laying of fiber optic cables is usually done with a cable laying machine that digs into the seabed. It is something similar to a plow that is used to plow a field.

And it is towed by the laying ship submarine wires. It has several rows of water jets at its base..

during operation, each orifice simultaneously shoots a jet of high-pressure water onto the seabed, that drags the sediment from the bottom and creates a fiber optic trench. And the top of the device has guide holes to direct the fiber optic cable to the bottom of the trench..

In the past, sand was often allowed to cover the trench naturally by currents to save the time of burying the cable. Today it is usual to clean the trench and bury the sand with this underwater machine equipped with a high pressure pump..

How to avoid corrosion by water?

Submarine fiber optic cables are highly susceptible to corrosion by seawater, since they are submerged in seawater for long periods of time.

Besides, hydrogen molecules can diffuse into the glass material of optical fibers, causing cable loss.

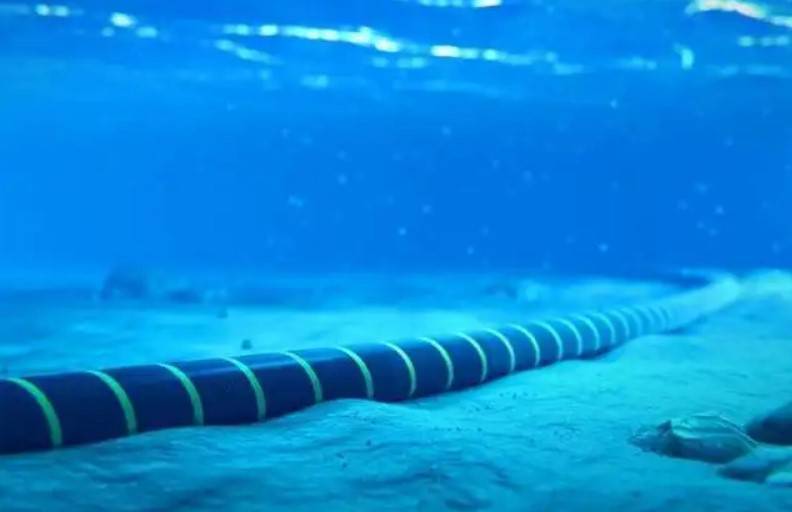

Therefore, fiber optic submarine cables are constructed by coiling optical fibers that have been treated with one or two coatings and reinforced with steel wire for its armor today.

The basic structure of the optical fiber submarine cable is usually: polyethylene cover, steel armor layer, aluminum waterproof coating, polycarbonate shell, copper or aluminum tube, paraffin, alkane layer, fiber bundle, etc.

Therefore, Its diameter is usually 69 mm and its weight is up to 10 kg per meter. It has a shelf life of more than 25 years.

This information is provided by ZMS Cable Group, a professional manufacturer of various cables and related accessories. If you have any questions, Contact us.