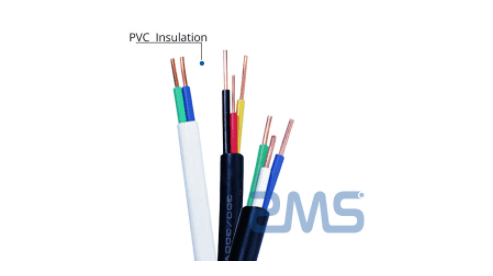

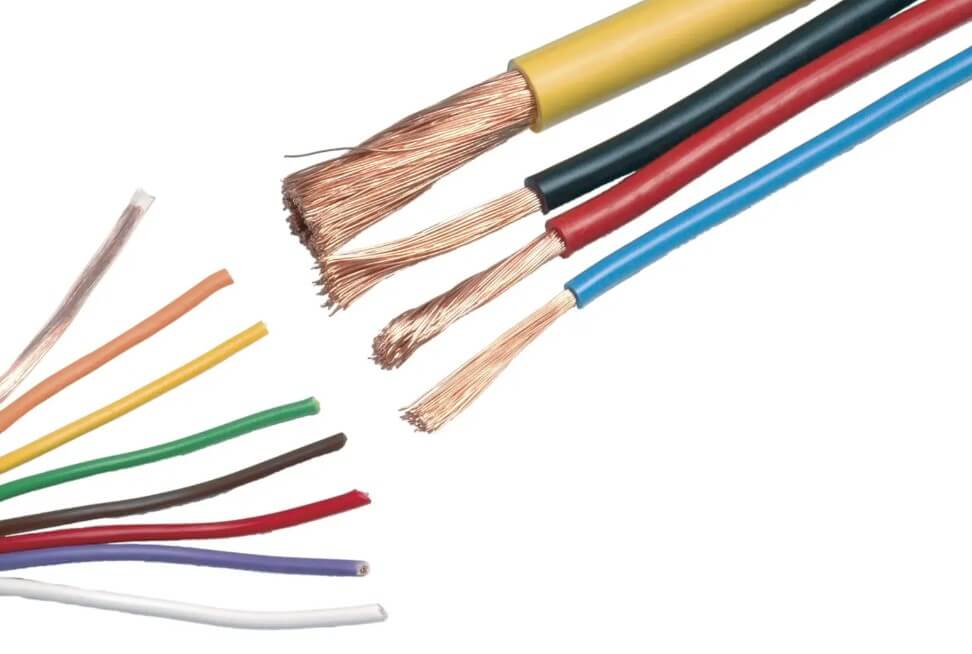

PVC cable material is manufactured from polyvinyl chloride as the base resin., to which stabilizers are added, lubricants and inorganic fillers. It is prepared by mixing, kneading and extruding.

Although this material has mediocre properties and is not environmentally friendly enough, it is less expensive and the process is simpler. So, PVC remains one of the most widely used cable materials.

When PVC material is used for cables, phenomena such as porosity can occur, surface roughness and brittleness. We discuss in detail how each of these phenomena can occur..

Porosity of PVC material for cables

1. High moisture content in raw materials. Raw materials that may have excess moisture are PVC resin, the plasticizer, filler and stabilizer.

Due to the relatively large number of additions, PVC resin and filler should be the focus of the inspection. This condition usually occurs during the kneading process and the evacuation process..

2. The poor stability of the formulation system or the excessive residence time of the material at high temperature. This causes the material to break down and pores to appear.. When this problem is serious, usually accompanied by a color change.

Surface roughness of PVC cable material

1. grains on the surface

Some unevenly mixed powders do not plasticize during extrusion, thus forming grains in the cable material. PVC resin particles that have not fully absorbed the plasticizer will also cause pimples., but usually smaller.

2. surface pitting

Usually, pitting is thought to be related to small molecules coming out of the material. These small molecules come from the resin, plasticizers and lubricants.

Since the production of cable materials requires vacuuming, it is reasonable to assume that these small molecules are extracted.

But through analysis, we found that these small molecules are produced in the material after aspiration. Many of them come from lubricants and plasticizers.

Poor Quality of Insulation of Cable Material

Due to the limitations of the PVC material and the influence of plasticizers, the PVC material insulation has certain limits.

For common cable materials, if the insulation is significantly worse, there are several main reasons for this.

1. excessive impurities

The mixture of impurities can have a negative impact on the cable material. Too many impurities can cause insulation problems.

These impurities can come from the PVC resin, of various auxiliaries and the mixing process.

2. Dust particles too coarse

The powder additives cable material are generally used only after grinding.

If this step is skipped or there is a mechanical failure, the added powder material is too coarse, will have a negative impact on the insulation of the cable material.

3. The problem of heavy metals in pigments

Many pigments are some heavy metal salts. These heavy metal ions will improve the electrical conductivity of the cable material and reduce its insulating properties.. Thus, the choice of material pigment is very important.

We hope this information can help you. ZMS Co., Ltd we offer several reliable and economical cables with technical assistance for their installation. If you have any questions, Contact us.