At the electrical installation stage during renovation, there are cables for electrical installations on ceilings and walls. These are conduits that contain wires and are used to carry electricity to places in the house where it is needed..

Classification of electrical installation cables for domestic use

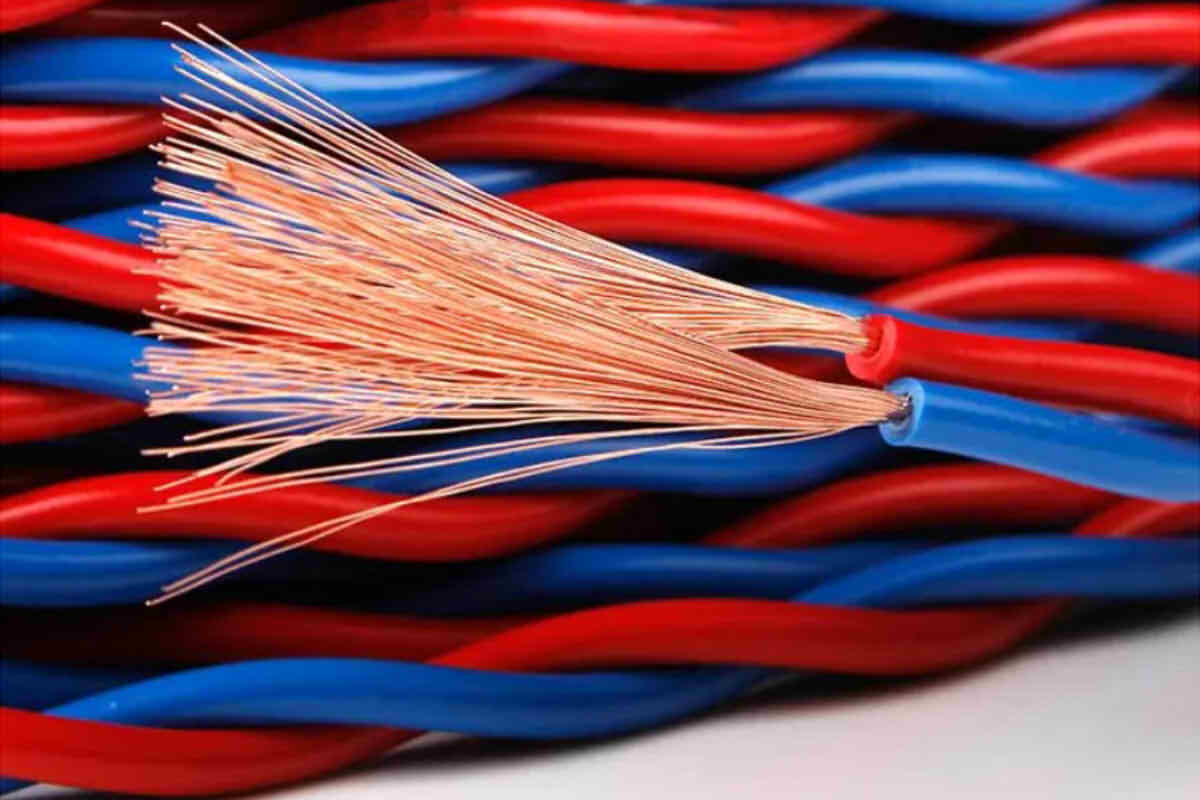

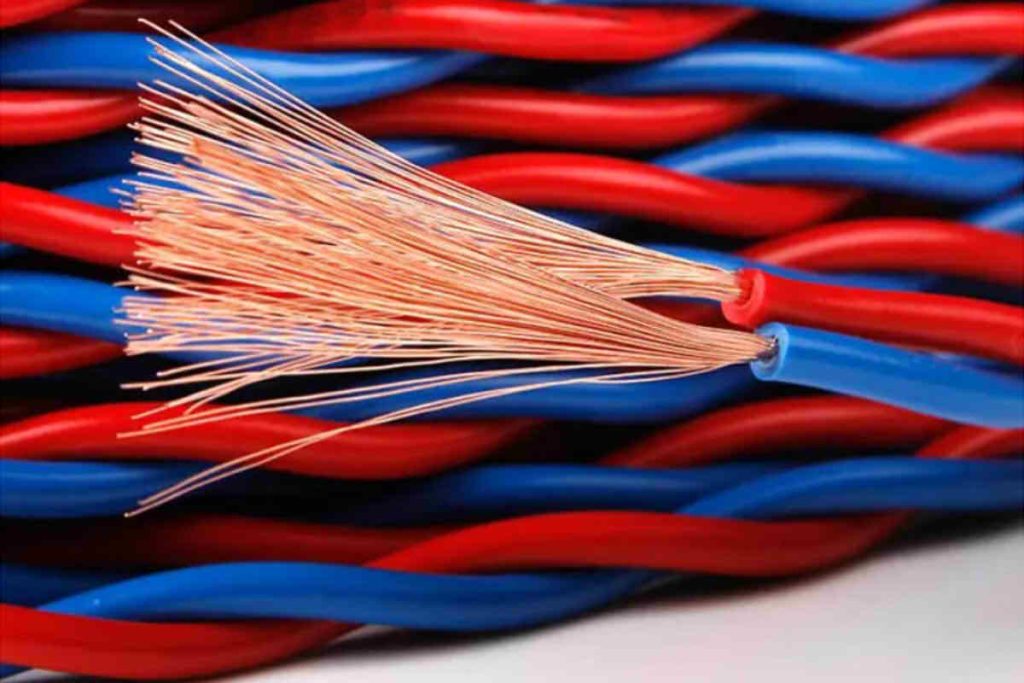

In general, Electrical installation cables for home use are divided into two types: rigid cables and flexible cables. Both types of cables have a copper core with a 99% de pureza.

Usually, rigid cables have a solid copper conductor, which gives them a longer useful life. Due to its small cross-sectional area, They are resistant to electrical currents and, Thus, They are most often used in residential installations. Nevertheless, They have the disadvantage of requiring more careful installation, as they can sometimes be damaged during installation, especially when bent into corners or subjected to excessive stresses.

Secondly, Flexible cables are made up of several copper wires and have a larger cross section, making them more susceptible to rust and giving them a shorter lifespan compared to rigid cables. This difference is especially notable in high electrical current applications.. Nevertheless, The advantage of flexible cables lies in their flexibility, making them suitable for applications where cables need to be moved or bent.

Cable sizes for domestic electrical installations

The dimensions of the cables used in installation residential refer to the diameter of the conductors, which is calculated based on the relationship between the diameter of the cable and the constant pi (Pi). In simple terms, the thicker the wire, the greater its cross-sectional area and, Thus, its load capacity. In the home electrical installation, cables are mainly used 1 square meter, 1.5 square meter, 2.5 square meters and 4 square meter, depending on the specific area.

- For main input wiring, The use of insulated copper wire is recommended. 6 square meter.

- For air conditioners in the living room, especially those of 2P or more, It is suggested to select an insulated copper cable of 4 square meter.

- The kitchen, which usually has the highest energy demand due to appliances, benefits from an insulated copper cable 4 square meter.

- Usually, for standard sockets that do not exceed 2500W power, It is recommended to use an insulated copper cable 2.5 square meter.

- In rooms with air conditioners up to 1.5P, It is suggested to use an insulated copper cable 2.5 square meter.

- in the bathrooms, where standard outlets do not include electric water heaters, It is advisable to use a insulated copper wire from 4 square meter.

- For electric water heater, It is recommended to connect it directly to the electrical panel using an insulated copper cable. 4 square meter.

Using different cable cross-sections in different areas can not only save money, but also ensures safe and reliable electrical charging.

How to buy cables for electrical installations

When selecting electrical cables for electrical installations, It is important to take into account the following aspects:

- Check cable dimensions. Make sure that the cable dimensions are within a margin of error of the 2%. The cable cross section should not exceed the 0.02% of mistake.

- Choose bright purple or red copper core cables. Quality copper cables should have a bright purple or red color and a shiny finish. They should feel soft to the touch. Fake copper cables are usually purple in color, yellow or white.

- Pay attention to the quality of the insulation. Poor quality cables may have insulation that appears thick, but actually, They are made from recycled plastic. If you apply a little pressure on the insulation, it is likely to peel off or deform.

- Note the size of the cable core. The number of cores refers to how many insulated wires are present within the sheath. If these wires are not insulated from each other, They are considered a single core. Two-core cables mean that two insulated wires are wrapped together and are generally used for appliances up to 220V.

- Check the weight of the cable. Los high quality cables They usually have a weight within the specified range. For example, A 1.5mm² insulated copper wire generally weighs between 1.8 Y 1.9 kg for each 100 metros.

Choosing cables for electrical installations that meet these criteria is essential to ensure the safety and efficiency of the electrical installation in the home..

Principles of cable construction for domestic installations

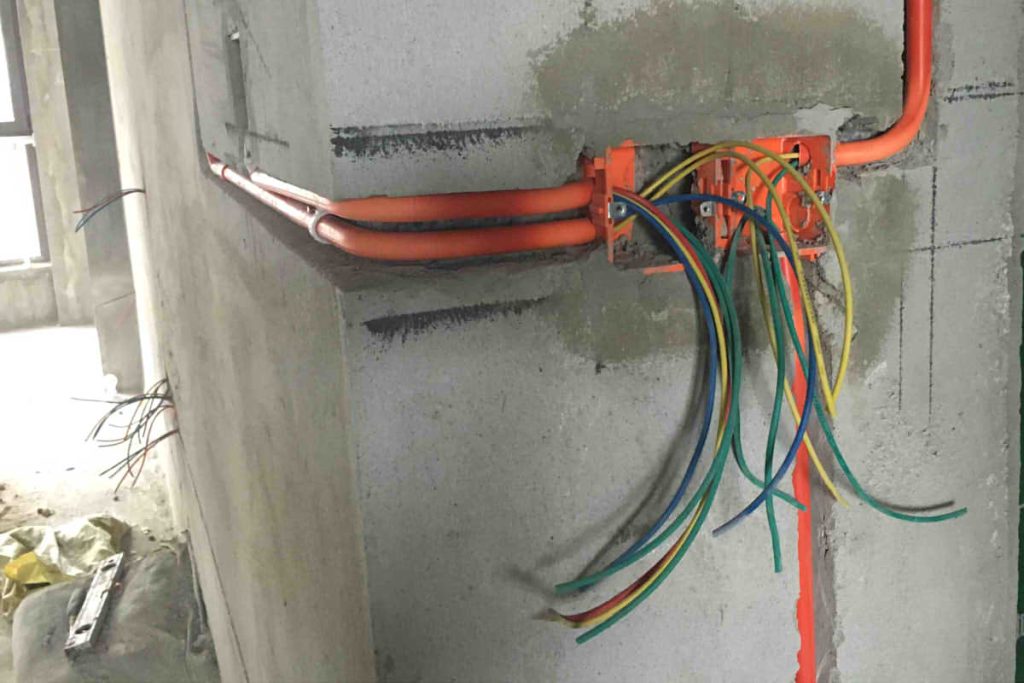

The construction principles for installing electrical cables in the home are as follows:

- Location: First, it is necessary to determine the location of the electrical circuits according to the needs, like the location of switches, plugs, and lights.

- Grooved: Once the location has been defined, electricians should make wiring slots according to the locations and directions of circuits. In standard practices, only vertical slots are allowed and horizontal slots are not allowed, since the latter could affect the load-bearing capacity of the walls.

- Cabling: Wiring is usually done by installing hidden conduits. There are two types of ducts: cold flexible steel conduits and PVC conduits. Steel conduits with cold flexibility are preferable, as they can be bent without breaking and allow easy replacement of cables without having to open the walls.

- Duct Bending: To bend steel conduits with cold flexibility, bending tool required. The bend radius should be approximately ten times the diameter of the conduit to facilitate efficient passage or replacement of cables..

These construction principles ensure a safe and efficient electrical installation in the home, minimizing damage to structures and facilitating future inspections and maintenance.

Precautions for wiring electrical installations

Here are the precautions to keep in mind when wiring for electrical installation:

- Do not mix high voltage and low voltage cables in the same conduit. Maintain a separation of 30-50 centimeters between high and low voltage cables to avoid interference, since high voltage cables can affect the television and telephone signal.

- The total cross-sectional area of the cables within the conduit must be less than 40% of the cross-sectional area of the protective duct. For example, in a duct 20, can be installed at most 4 cables 2.5 square meter.

- For long distances, it is preferable to use entire ducts rather than individual segments.

- If it is necessary to connect ducts, use gaskets and seal the joints and duct well with adhesive.

- If the length of the installation exceeds 15 meters or has three or more curves, a junction box must be added at the intermediate point.

- Usually, keep a distance of at least 40 centimeters between electrical cables and heating and gas pipes, unless there are specific requirements.

- Unless otherwise specified, install the sockets at a height of 30 centimeters above the ground.

- In home decoration, electrical cables should only be connected in parallel.

- If specific colors have been defined for the phase wires, neutral and ground during installation, Be sure to use these colors on all connections at all times.

- Separate and group lighting power lines, plugs, air-conditioning, water heaters, etc., in different areas. This guarantees that, in case of maintenance or repair, a part of the electrical installation can be disconnected without affecting the operation of other devices.

- After completing the electrical installation, make sure you get a electric cable layout plan by the contractor. This is essential for future wall maintenance or renovation work., as it helps prevent accidental damage to cables.