The mineral cable is the first fire cable, originated in Switzerland, later developed by the UK to a specific scale and custom fire standard BS6387 standard.

MICC cables generally refers to mineral insulated cables.. My cable can also be divided into mineral insulated cable and mineral fire resistant cable..

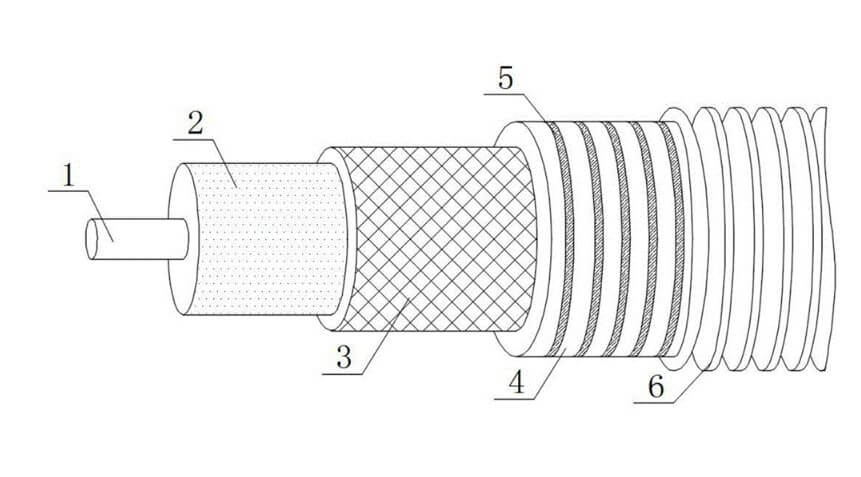

The cable MICC it is a wire of inorganic material. The outer layer of the cable is a seamless copper jacket. Between the sheath and the metal core is a closely compacted magnesium oxide insulation layer.

Mineral insulated cables are divided into different uses: heating thermocouple wires, compensation cables, special cables, etc.

Mineral Insulated Cable Applications

Mineral insulated copper wire itself does not cause fire. Not likely to burn out and can continue to provide power in the event of a fire near the melting point of copper.

It is a true sense of fire resistant cable. High-rise buildings are used, petrochemistry, airports, tunnels, boats, offshore oil platforms, aerospace, iron and steel metallurgy, malls, parking lots and other occasions.

Although the performance of mineral insulated cable is strong, most people think that the price of Micc cable is high and it is not used.

In recent years, with the continued efforts of manufacturing plants and material suppliers, the price of mineral insulated cable is continually approaching the costs of ordinary cable.

Production of mineral insulated cables

The production process of mineral insulated cables and the necessary equipment are more professional. We will introduce three ways of mineral insulated cable production processes.

the first process

The first process is also the earliest and most commonly used porcelain column mounting method..

Most manufacturing and manufacturing mineral insulated cable manufacturers are currently using this process..

It uses a sintered magnesium oxide porcelain column that is hand-filled with the copper tube and copper rod between and after a series of annealing of the final product..

The biggest drawback of this cable manufacturing and production process is the labor intensity and low production efficiency..

the second process

The second process is called the magnesium oxide powder filling method.. It is like a funnel between the vertical copper rod and the copper tube filled with magnesium oxide powder..

This process can cause the conductor concentricity and the cover is better. But this production crew is almost weird.

In the filling process, magnesium oxide powder may be wet. The production workshop requires to be sealed and dry. Air humidity requirements are more stringent.

the third process

The third production process is the world's most advanced copper tape longitudinal welding method.

The principle of this mineral insulated cable production process is that the copper belt and copper rod can be infinitely welded, and let the longitudinal welding molding of the copper belt wrap the copper rod.

On the copper rod and the solder between the copper belt filled with magnesium oxide powder.

The main production equipment of mineral insulated material

The main production equipment of the mineral insulated material it is a wire drawing machine, an extruder, a wire machine, a braiding machine, a fork twisting machine, an inverted wire machine, a wire measuring machine, a pooling machine, etc.

Advanced powder infusion equipment has also been introduced magnesium oxide, mineral insulation layer processing equipment, longitudinal copper cladding equipment, etc.