Coaxial cable is a cable that consists of a copper conductor, an isolation, a woven net and an outer cover. It can be used for transmission of analog and digital signals, including cable tv, long distance telephony, local area networks of computers, etc.

The quality of the coaxial cable has a major impact on the quality of the signal transmission. The following are ways to check the quality of coaxial cables.

1. Observe the integrity of the insulation

Standard coaxial cables have a highly rounded cross section with the outer conductor and aluminum foil adhered to the outer surface of the insulation..

The more rounded the outer surface of the insulation, the smaller the gap between the foil and your appearance. The less rounded, the greater the separation space.

Practice shows that the smaller the separation, the better the performance of the cable. Besides, large gap allows air to enter sheath and affects cable life.

2. Measure the consistency of coaxial cable insulation

Fluctuations in the diameter of the coaxial cable insulation mainly affect the return coefficient of the cable.

You can cut the insulation from a section of the wire and carefully check the outside diameter of each point with a micrometer to see if it is consistent..

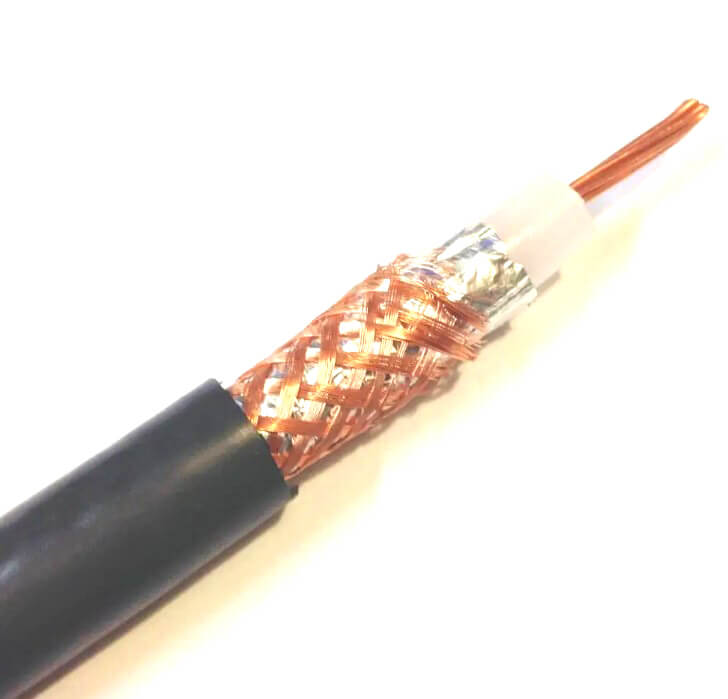

3. Measuring woven network of coaxial cable

The woven network of coaxial cable plays an important role in the performance of appantallamiento. So, coaxial cable quality inspection should see whether the woven net is tight and flat.

The way is to cut a small section of the woven net of the coaxial cable and check the number of the woven net. If the number is consistent with the indicators given, the cable is qualified.

Besides, a single woven wire can be measured with a spiral micrometer, the thicker the diameter of the wire, the better the quality.

4. Check the quality of aluminum foil

An important shielding in coaxial cables is aluminum foil that prevents open-circuit external signal interference and TV signal exposure.

They should check the quality of the aluminum foil of coaxial lines new.

First, the cover can be cut and see if the surface of the braided mesh and aluminum foil retains a good shine.

In second place, you can take a section of the wire and wind it tightly around a small metal shaft. After straightening and reversing the winding several times, open the cable cover to see if the aluminum foil is torn.

You can also cut a small section of aluminum foil and rub and stretch it on your hand repeatedly., if it doesn't break after many times, are the qualified products, otherwise they are the inferior products.

5. Check the firmness of the outer cover

High quality coaxial cable outer jacket wraps very tightly, in order to reduce the gap within the armor layer and prevent oxidation from air ingress.

It can also prevent the deviation of electrical properties caused by the relative slippage of the shielding..

Nevertheless, wrapping the conductor too tightly can cause inconvenient head stripping and make it difficult to build.

The check method is to take 1m long cable and remove the cover at the end. If the inner core cannot be forced out at the end of the shell, that's appropriate.

6. Observe the way of storing the cable

The way to store cables is not just a matter of aesthetics, but also of quality. If the wires are held in the same concentric plane and are in parallel circular contact with each other as a whole, will reduce the forces of interaction in the cables.

Proper storage makes cables less likely to become deformed and damaged when stacked.

We hope this information can help you. ZMS GROUP we offer several reliable and economical cables with technical assistance for their installation. If you have any questions, Contact us.