TPU cable is thermoplastic polyurethane cable. It is one of the new types of electric cables on the market. TPU is a thermoplastic elastomer made up of a linear block copolymer containing hard and soft chain segments.. This synthetic polymer is robust and durable., making it an excellent choice for use on cables.

Table of Contents

– what is tpu cable?

– Types of TPU Materials

– TPU Material Manufacturing

– Application Fields of TPU Cable

– Characteristics of TPU Electrical Cables

– Differences between TPU and PVC Cables

TPU is a meltable material that is easy to mold. So, can be used for injection molding and does not melt under optimal conditions. The invention of this thermoplastic cable is one of the breakthroughs in the industry. In recent years, TPU has gradually replaced many materials, especially PVC and synthetic rubber, in different applications.

It is electrical insulated wire can be rolled up for storage and used outdoors in extreme weather conditions. TPU cables are very stiff, flexible at low temperatures, abrasion and environmental resistant. The use of this new material considerably extends the durability and life of the cable.

Types of TPU Materials

The raw material used to manufacture TPU cables determines the type of application for which it is used. Till the date, there are three main types of this material. They have different properties and resistance levels.

Polycaprolactone: This material is based on low temperatures. It has great resistance when combined with other materials.

Polyether: It has good resistance to hydrolysis and abrasion and is designed for work at low temperatures..

Polyester: It is a very flexible material and compatible with other materials. Not affected when exposed to chemical reactions.

TPU Material Manufacturing

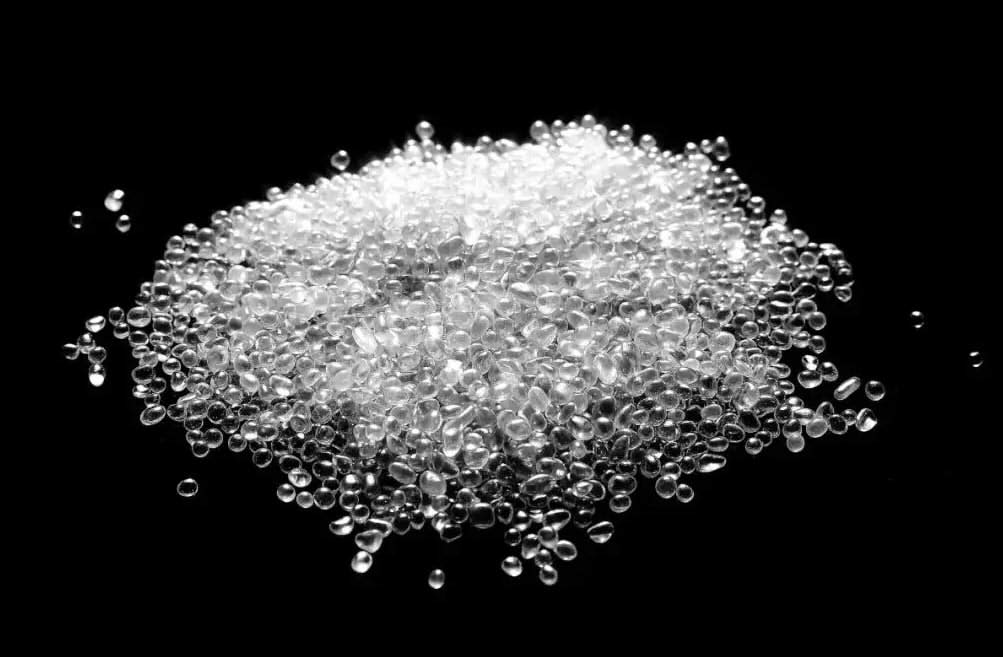

TPUs can be made by a chemical reaction between diisocyanates and diols. As an alternative, polyols with long and short chain diols can be used. Next, These materials can be made into coatings of TPU cables using an injection molding process, since it is a thermoplastic material suitable for melting.

Application Fields of TPU Cable

TPU cables are used in agriculture, the industry, the chemical and petroleum sectors, car manufacturing, hydraulic control systems, the construction sector and many more. Like other flexible cables, is suitable for applications that require frequent bending or movement. Its fields of application are the following.

automation: Cables for anti-lock systems (ABS), odometer cables, communication cables for cars, cables for charging stations

Geoprospection: geophone cables, oil prospecting cables, land and sea prospecting cables

electronics: Cables for mobile chargers, audio cables, cables USB, telephone wires, cables for computer accessories

Medical equipments: ECG leads, blood oxygen detection cables, massager cables, electrode cables

energy and industry: railway cables, marine cables, drill cables, military cables, solar power cables, wind power cables, industrial equipment cables, mining cables, cables CNC, Power cables, lifting equipment cables, drag chain cables, aerospace cables.

Telecommunications and communications: Optical fibre wires, data cables

Characteristics of TPU Electrical Cables

TPU material cables offer effective defense against harsh environmental conditions. This makes them highly appreciated in the industrial sector.. These types of wires and cables offer a wide variety of excellent qualities.

environmental protection: This cable has passed environmental tests. Does not cause harm to the environment or people during use.

Flexibility: TPU is easy to mix with other materials. This makes it easy to manufacture and customize..

Protection: Despite its great flexibility, the TPU cable has a very rigid exterior that effectively protects the conductors.

Abrasion resistance: The new material increases the durability and sustainability of the cable.

UV resistant: When the cable is exposed to sunlight, TPU blocks UV rays from reaching drivers.

Resistant to extreme temperatures: The TPU material shows no damage even when exposed to high temperatures for long periods of time. In addition, provides optimal elasticity even at low temperatures.

Chemical resistance: TPU cables are resistant to external chemical reactions.

Differences between TPU and PVC Cables

TPU has great strength and hardness that other plastics and rubbers cannot match.. It is also resistant to oil, to the cold, to aging and can degrade. It is an ideal alternative to PVC in many industrial and civil applications..

PVC cables tend to stiffen in winter. Instead, the TPU cable is extremely resistant to cold. Its elasticity and other properties do not deteriorate even at -35 Celsius degrees. Besides, TPU has good processing properties. Can be injection molded, extrusion and calendering.

PVC is not very respectful of the environment due to the numerous additives that must be added. the tpu, instead, it is a non-toxic material, odorless and environmentally friendly. It is easy to recycle and decompose and can be reused. Therefore, has a wide range of applications in many fields, such as electrical cables and industrial films.

One of the main advantages of TPU over PVC is that it does not require plasticizers to get flexibility. The TPU material does not require special equipment for processing or handling and can be easily sterilized by various methods..

Besides, TPU is much stronger than PVC. Products made with it are not only more durable, but they use less material, which saves production costs.

Although the cost of TPU cables is currently higher than that of PVC cables, its excellent performance has led TPU to gradually replace PVC in the wire and cable industry. ZMS electrical cable manufacturer provide customers with high quality TPU flexible cables at cost-effective prices. If you have any questions about the cables, Contact us.