During cable laying in winter, Many workers find that good quality cables harden and insulating jackets become damaged and peel off.. Los cable manufacturers Insists on offering the qualified products. This often leads to misunderstandings between the two parties.. In fact, It may not be a product quality problem., but more a result of the harsh winter temperatures.

Causes of Cable Problems in Winter

The outer jackets of wires and cables are usually made of PVC or rubber.. When exposed to subzero temperatures, they become hard and brittle. This causes the cable sheaths to be damaged and fall off at the slightest external force..

In winter, the outside temperature is usually below zero and the ground temperature can be even lower. Whether wires and cables are left outside or directly on the ground, problems such as cracking of the outer skin are likely to occur.

Use of Electric Cables in Low Temperature Environments

Whether the cables are to be used in low-temperature environments, can be coated with antifreeze. The antifreeze coating forms a diaphragm between the cable surface and the ice crystals. Actively reduces the contact area between the outer shell and snow and water, reducing the friction. Frost protection can be achieved by insulation.

When selecting cable materials, cold-resistant cables must be used. There is a wide range of special cables, including those that can be used at extreme temperatures. Special cables for resistance to low temperatures are the best option for outdoor use in winter.

Low Temperature Resistant Cables

Ordinary material PVC can be used normally between -5 y 10°C. Even special PVC can remain flexible at -30°C. Nevertheless, when the temperature drops to -40 °C, -50 °C y -60 °C, or even less, it is difficult to guarantee that the outer skin does not freeze and crack.

To be able to use the cables for longer and more safely in winter, you have to work on the level of resistance to the temperature of the material. Low temperature resistant cable using specially formulated materials has excellent cold resistance properties. Can be successfully used in cold winter months or low temperature environments. The cable jacket has good mechanical and electrical properties at ultra-low temperatures., even when subjected to external forces. This greatly improves the safety and lifespan of electrical cables..

Los flat flexible cables are made of nitrile and are used at temperatures from -40°C to +90°C. These flat cables are mainly used for electrical connections in power and control systems in heavy industry.. Heavy transport machinery and container cranes and other large machines require these types of cables.. Thanks to its cover that does not crack in low temperature environments, as well as its resistance to abrasion and oil, flexible flat cables are widely used.

Cables for use in liquid nitrogen or liquid oxygen environments require a cold resistance of -200°C. Cables made from PCTFE can meet this requirement.. Although this material is more expensive, is irreplaceable. This is because, in extremely cold environments, other cable materials would freeze and break instantly.

Precautions for Cable Laying in Winter

For laying electrical cables, you have to prepare it completely. Before the arrival of winter construction, affected construction personnel should organize to study construction and precautionary measures. You should also familiarize yourself with the construction drawings and technical documents for laying.

It is necessary to make a good plan of materials. The materials department should, according to plan, do a really good job of supplying the necessary materials. Include insulating materials, antifreeze, anticold, non-slip, heating, etc. Before the works start, it is important to make sure that the roads are clear of snow and ice.

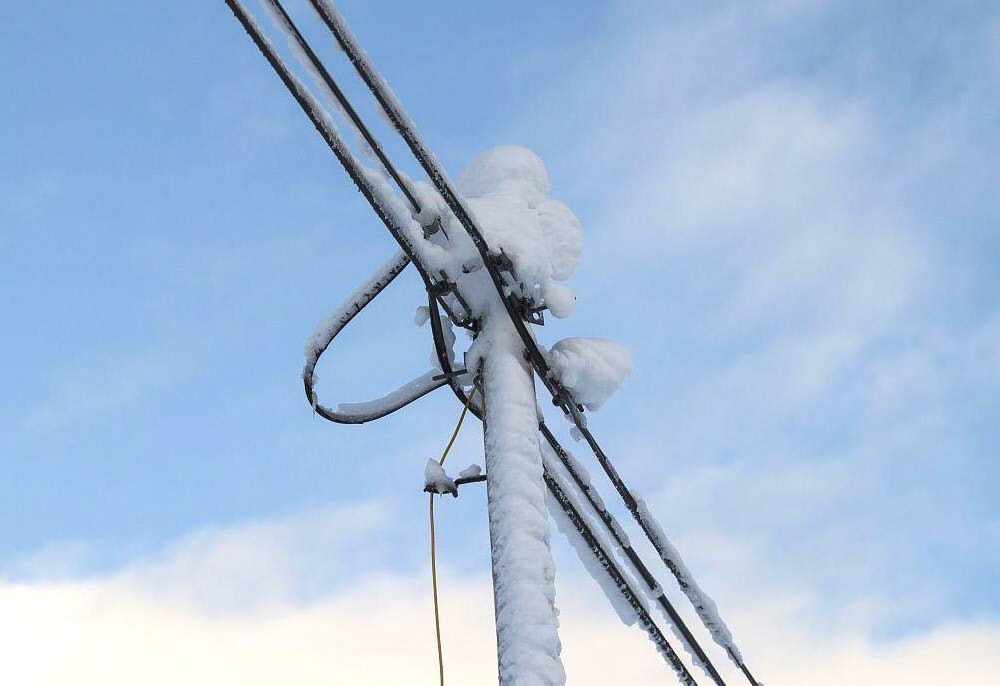

Las outdoor cable lines they are easily covered with snow and ice in winter. When the weight of the ice exceeds the capacity of the cable, can easily cause poles or transmission towers to collapse or cable break under tension. to avoid it, choose the type of cold-resistant cable.

When tending to ambient temperatures below 0 °C, it is necessary to move the cables to a house with a temperature of about 25 °C to preheat it. Once the cables have reached the necessary temperature, are fast tracked. The laying time should not be too long. Must stay within 4 hours. It is not advisable to lay the cables in the morning or at night.

Winter Cable Damage Prevention Measures

Factory and Transportation

When the cables are loaded on the transport vehicle at the factory, must be kept warm and protected. Closed means of transport may be used to avoid direct exposure of the product. The cable tray can also be padded with a soft cushion, such as bedding or other soft foam. Avoid excessive bending of the cable by carrying it carefully.

unloading

Personnel can be placed to supervise and prevent careless handling of cable products during unloading.

Storage

It is better to store cable products indoors. Lay a barrier layer, like a wooden board, linens, foam, etc., on the surface of the storage area. This will prevent the cables from freezing and getting wet.. Care must also be taken to prevent the skin of the cable from being scratched by direct contact with the ground..

Lying

The best time for cable laying is at noon or in the afternoon, when the temperature is higher. If possible, wires can be pre-heated with equipment such as a heater before use in order for the product to reach its best performance. In case of underground laying of cables, a protective layer can be previously placed, like canvas or foam, in the cable trench.

If placed through a pipe, make sure the inside and outside of the pipe are smooth to avoid scratching the wires. If you use iron pipes, you should pay special attention to the purchase of quality iron pipes. Poor quality iron pipes may have a large number of sharp protrusions inside., that can scratch the outer skin of the cable.