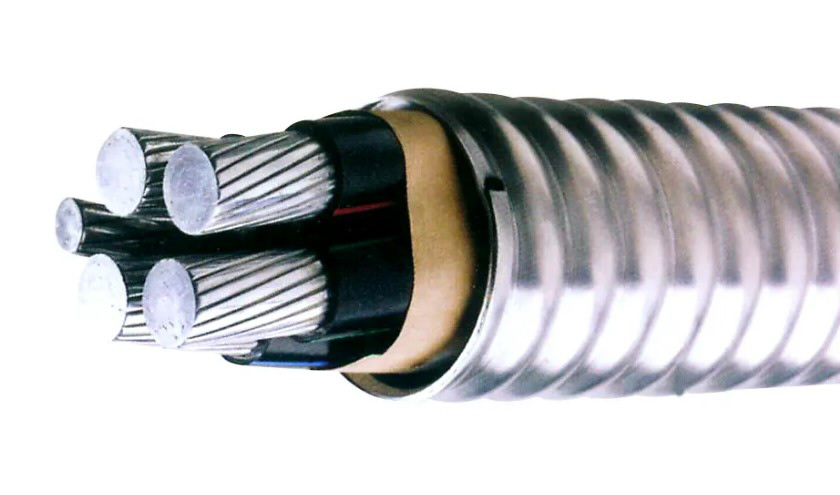

Electrical armored cable is cable equipped with a hard armor layer on the outside of the conductors.. Armor structure effectively protects electricity conductors from external damage. These types of cables are often used for buried installations in harsh environments. They're safe, reliable, resistant to animal bites and protect against acid and alkali corrosion.

The Use of Armored Electrical Cables

The addition of a layer of metallic armor to the cable improves its protection in terms of tensile and compressive strength.. So, also prolongs the life of the cables. Besides, resistance of the cable to interference can be improved by shielding protection. Metal armor also prevents tearing by rodents.

The bending radius of the armored cable must be large, and the armored layer can be grounded to protect the cable.. Armored electrical cables are usually fixed-lay power cables. In simple terms, they are the cables that are fixed in one place and basically do not move.

The most commonly used armor materials are steel tape, the steel wires, the aluminum tape, the aluminum tube, etc. The reinforced layer of steel tape and steel wires has a high magnetic conductivity and has good magnetic shielding effect.

This type of armored cable can resist low-frequency interference and can be placed directly buried without the use of conduit.. In general, steel electrical armored cables are less expensive and are more common in practice.

Advantages of Electric Armored Cables

The robust nature of armored cables makes them ideal for outdoor applications., industrial and military. These applications include, in particular, factory automation, petroleum and chemical manufacturing and processing networks.

One of the greatest advantages of armored cables is their crush resistance index. Los metal armor cables typically have a crush strength of up to 1500PSI, which makes them very suitable for almost any industrial application. Besides, the stainless steel armor of these cables is resistant to corrosion problems common in extreme environments.

Plastic armor is not as durable as metal. But achieves an extremely high level of crush and abrasion resistance compared to unarmoured cable jackets. Plastic armored cables typically have a crush strength of up to 800PSI.

Faults in Armored Cables

The production process of the electrical armored cable is complex and, so, its failure rate is high. There are two reasons for the failure of armored layer cables..

1. If the wiring process of the central end of the armored cable does not meet the quality requirements, the cable will fail. Therefore, the requirements of the wiring process, paying particular attention to handling the mid-end insulation. Do not allow moisture to enter critical connections to prevent it from affecting your insulation.

2. Cracks in the steel armor of the cable, poor overlaps and cracks in the lead package are especially likely on cables with weak end connections. So, the cable insulation is damaged and causes a short circuit. It must be taken into account that the radius of curvature of the armored cable must not be too small., and must not be less than 20 times the outer diameter of the cable.