solar cables, also known as cables PV, are the components of the solar system to connect the panels of the photovoltaic power system. Photovoltaic power generation is based on the principle of photovoltaic effect.

Uses solar cells to convert energy from sunlight directly into electricity. Photovoltaic power systems consist of three main components: solar panels, regulators and inverters.

The sun contains a huge amount of energy, But in practice the use of solar energy is very scarce. Plants around the world only use among the 1% and the 5% of solar rays.

While the most efficient solar technology available to humanity today can only overcome the 50% In the laboratory, and industrial use usually achieves a maximum of the 40%, The middle photovoltaic cell can reach between the 20% and the 25%.

Solar systems work in difficult environments and are used mainly abroad. Its operating characteristics and the characteristics of the application environment determine the special requirements for the performance of the solar cables.

High temperature resistance property

First, It must be heat resistant. On a sunny day, Prolonged sunshine exposure can cause the temperature to be triggered to the 100 Celsius degrees.

Los PVC ordinary cables and rubber are not able to function at such high temperatures, So special photovoltaic cables are needed.

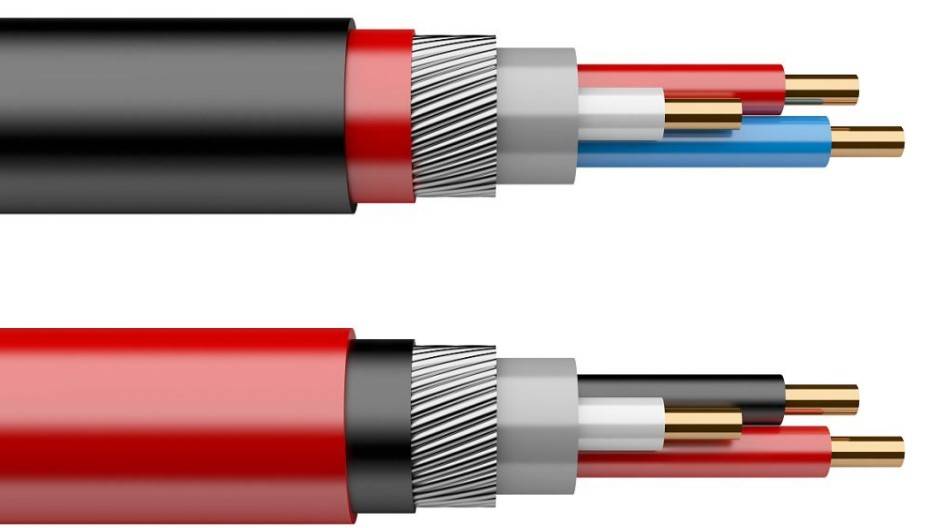

Irradiated reticulated polyolefin is used for the insulation and coating of solar cables. After irradiation by an irradiation accelerator, The molecular structure of the material is altered to provide several performance aspects.

Solar cables have a 120 ° C nominal temperature. At this temperature they can be used during 20.000 hours. This corresponds to 18 years of use at a continuous temperature of 90 ° C.

And when the temperature is less than 90 ° C, useful life is even greater. As a rule, Solar teams are required a useful life of 20 a 30 years or more.

Instead of special cables for solar systems, Some contractors use 90 ° C rubber cables or 70 ° C PVC cables to save costs. Obviously, This will significantly affect the life of the entire solar system.

Corrosion resistance property

How they work abroad, Solar cables must also have a certain degree of corrosion resistance. It must be resistant to a certain chemical corrosion to ensure that the equipment has enough adaptability to the environment.

Mechanical Resistance Property

During installation and maintenance, Solar cables are subject to strong external forces such as pressure, flexion and stretch.

And The coating of the cable is not resistant enough, The cable will be damaged. Therefore, It is essential that solar cables have enough mechanical resistance.

This will ensure that the PV cable is safe to use and that there are no short circuits or fire risks.

With the growing awareness of the protection of the environment and the development of green energy technologies, Photovoltaic technology is increasingly used worldwide.

In addition to the rapid development of photovoltaic plants backed by the Government, Private investors are also actively participating. The solar cable market seems to have great potential.

This information is provided by ZMS Cable Group, a professional manufacturer of various cables and related accessories. If you have any questions, Contact us.