ZMS Cable supplies submarine cables to the transmission line project 132 kV Osogbo/Olorunsogo. This project, led by Nigerian Transmission Company (TCN), marks a crucial step to improve Nigeria's energy infrastructure and address the nation's growing energy needs.

Table of Contents

- Project summary

- Energy Developments in Nigeria

- ZMS Cable Paper

- Technical Details of Submarine Cables

- Fabrication process

- Challenges and Solutions

- Prospects for Future Cooperation

- Conclusion

Project summary

The submarine transmission line project 132 kV Osogbo/Olorunsogo is a critical initiative aimed at strengthening power transmission capabilities between Osogbo and Olorunsogo. This project is part of a broader effort by TCN to modernize and expand Nigeria's power grid., ensuring reliable and efficient electricity transmission throughout the country.

The project involved the manufacture and supply of 7,000 Metters of submarine cable by ZMS Cable. These cables are built with a complex and robust design: CU/XIPE/CWS/Poli-AL Tape/PE/Apilado/PE/SWA/PE (IMPERMEABLE) 132kV 1x1200mm² with single-mode fiber optic cable. Advanced construction ensures the cables can withstand the harsh underwater environment while transmitting high voltage power and fiber optic signals.

Energy Developments in Nigeria

Nigeria, with its rapidly growing population of more than 160 millions of people, has faced significant challenges in meeting its energy demands. The Federal Government of Nigeria recognized the need for power sector reform, which led to the disintegration of the National Electric Power Authority (NEPA) in smaller, more efficient units. TCN, incorporated in November 2005, emerged from this restructuring as one of the 18 independent business divisions of the Electric Power Company (PHC).

Since then, TCN has been granted multiple licenses for power transmission and system operations. Its main responsibilities include operating and expanding transmission facilities, establish efficient transmission networks, ensure network reliability and reduce transmission losses to less than 5%.

The Osogbo/Olorunsogo project is a testament to TCN's commitment to improving the Nigerian energy infrastructure. By improving connectivity between key regions, The project aims to ensure a stable and reliable energy supply, supporting economic growth and industrial development.

ZMS Cable Paper

ZMS has been at the forefront of submarine cable technology for many years, with a supply history of more than 53.8 kilometers of submarine cables worldwide. For the Osogbo/Olorunsogo project, ZMS Cable participated in all stages, from structural design of submarine cables to packaging, transportation and advisory support for installation and construction.

The cables supplied for this project feature a state-of-the-art design that ensures both durability and efficiency.. The inclusion of a singlemode fiber optic cable within the power cable structure allows for seamless communication and monitoring, which is crucial to maintain transmission line integrity and performance.

Technical Details of Submarine Cables

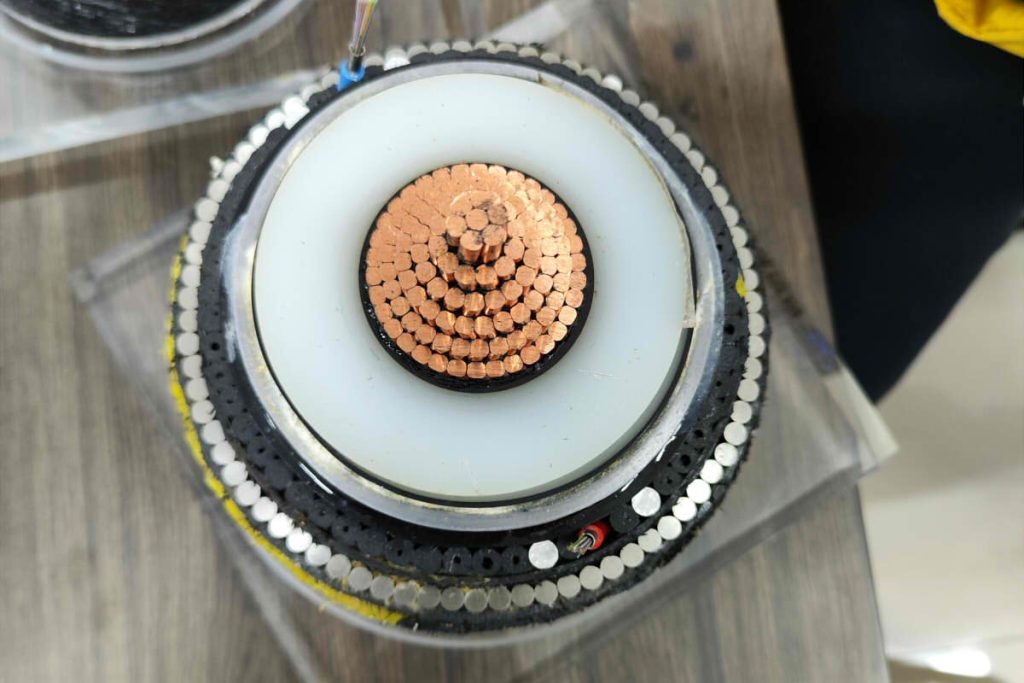

The cables provided for this project feature sophisticated multi-layer construction to ensure durability, reliability and efficiency. The specific structure includes:

- Conductor: High conductivity copper core (CU), providing excellent electrical conductivity and low resistance.

- Isolation: Cross-linked polyethylene insulation (XIPE), offering superior electrical properties and thermal stability.

- Driver Screen: Semiconductor driver screen (CWS), which ensures uniform distribution of the electric field and minimizes stress.

- Barrier Layer: Poly-aluminium belt (Poli-AL), providing additional mechanical strength and moisture resistance.

- Envelope: polyethylene wrap (PE), known for its high mechanical resistance, flexibility and chemical resistance.

- Armor: Shielding steel wire (SWA) for enhanced protection against physical damage and underwater conditions.

- Impermeability: Integral waterproof design to prevent water ingress and ensure long-term operational integrity.

- Fiber Optic Integration: Single-mode fiber optic cable integrated into the power cable structure, allowing real-time data transmission and system monitoring.

The technical design of these cables ensures that they can withstand the harsh underwater environment, including pressure, temperature variations and potential mechanical impacts, while maintaining optimal performance.

Fabrication process

ZMS uses a rigorous manufacturing process to produce these high-performance submarine cables. The process involves:

- Materials selection: Use only the highest quality materials to ensure product reliability and longevity.

- Extrusion: Precision extrusion of insulation and wrap layers for consistent thickness and uniformity.

- Armor: Application of steel wire shielding through a meticulous process that ensures the integrity and robustness of the cable.

- Waterproofing: Implementation of advanced waterproof sealing techniques to prevent any moisture ingress.

- QA: Extensive testing and quality assurance at every stage of production, including electrical tests, mechanical and environmental.

By adhering to these rigorous manufacturing protocols, ZMS Cable ensures that each submarine cable meets international standards and customer specifications.

Challenges and Solutions

The submarine transmission line project 132 kV Osogbo/Olorunsogo presented several unique challenges, that required innovative solutions and strategic planning to overcome.

Environmental conditions

Challenge: The underwater environment posed significant challenges, including high water pressure, variable temperatures and potential mechanical impacts from underwater currents and debris.

Solution: ZMS Cable designed the submarine cables with robust multi-layer protection, including steel wire shielding and polyethylene wrap, to withstand these harsh conditions. Waterproof construction ensured no water ingress, maintaining long-term cable integrity and performance.

Logistical Obstacles

Challenge: Transport and install 7,000 meters of submarine cable required meticulous planning and coordination, given the weight and size of the cables.

Solution: ZMS worked closely with TCN to devise a comprehensive logistics plan. This included specialized transport vehicles, coordinated shipping schedules and careful handling procedures to avoid any damage during transit. The installation phase was supported by technical experts from ZMS Cable, who provided on-site guidance and ensured cables were installed correctly and efficiently.

Technical Complexities

Challenge: Integrate energy transmission and communication by fiber optic inside cable unique added a layer of technical complexity, demanding precise engineering and execution.

Solution: ZMS Cable leveraged its extensive experience in fiber optic and power cable technologies to develop seamless integration. Single-mode fiber optic cable was integrated within the power cable structure without compromising electrical or mechanical properties. Advanced testing procedures implemented to validate the performance of power and data transmission capabilities.

Emergency Management

Challenge: Unforeseen challenges, such as weather conditions or technical problems on site, required quick and effective responses to avoid project delays.

Solution: ZMS Cable established a dedicated project management team to monitor progress and address any issues promptly. The team was equipped with contingency plans and the necessary resources to handle emergencies efficiently. This proactive approach ensured that the project stayed on track and was completed within the stipulated time frame..

By addressing these challenges with innovative solutions and strategic planning, ZMS Cable demonstrated its commitment to excellence and its ability to successfully deliver complex projects. The experience gained from the Osogbo/Olorunsogo project has further strengthened ZMS Cable's ability to handle future submarine cable projects..

Prospects for Future Cooperation

Successful collaboration between ZMS and TCN on the Osogbo/Olorunsogo project opens new avenues for future cooperation.

Mr. Zhai, ZMS Cable project manager, declared: “We are honored to be part of this significant project that will improve Nigeria's energy infrastructure. Our team has worked diligently to ensure that the

submarine cables supplied for the Osogbo/Olorunsogo project meet the highest standards of quality and reliability”.

Looking to the future, added: “We look forward to continuing our partnership with TCN and contributing to more projects that will boost Nigeria's energy sector.. Our experience with the Osogbo/Olorunsogo project has been invaluable, and we are excited about the prospects of future collaborations that will bring more innovative solutions to Nigeria”.

Conclusion

The submarine transmission line project 132 kV Osogbo/Olorunsogo is a landmark achievement in the Nigerian power sector, made possible through the collaborative efforts of TCN and ZMS Cable Supplier. This project not only addresses immediate energy transmission needs, but also lays the foundation for future advances in the country's energy infrastructure.

As Nigeria continues to grow and develop, The importance of reliable and efficient power transmission cannot be underestimated. ZMS remains committed to supporting this growth through innovative solutions and strong partnerships..