In the energy sector of Mexico, significant collaboration is leading the wave of electrical infrastructure modernization. The Federal electricity commission (CFE), the leading electricity supplier giant in the country, has reached a cooperation with the renowned cable manufacturer ZMS. This collaboration focuses on the L.T project. CARMEN BEACH – CHANKANAAB II, which aims to comprehensively update the electricity transmission system in the region through a mixed underground-submarine-underground construction, thus guaranteeing a stable electricity supply for the Mexican population and socioeconomic development.

ZMS, with its outstanding capability in cable design and manufacturing, has managed to gain the trust of the CFE. This collaboration not only marks another important milestone for ZMS in the global market, but also reflects the high importance that the CFE gives to technological innovation and international cooperation., jointly promoting the efficient development of the energy industry in Mexico.

Background and Significance of the Project

Since its foundation in 1937, the CFE, as a key state-owned enterprise under the federal government of Mexico, has been dedicated to providing electrical services throughout the country in the most economical and efficient way possible. Its vast transmission network covers more than 110,000 kilometres, and the distribution network reaches almost 883,000 kilometres, With 2,275 substations and more 50,000 kilometers of fiber optic cables of the national telecommunications network, constituting a solid support for Mexico's energy supply. Faced with the urgent national need for energy security and sustainable development, The CFE is accelerating the modernization of the electrical grid to ensure the reliability and sustainability of the energy supply.

Collaboration Details

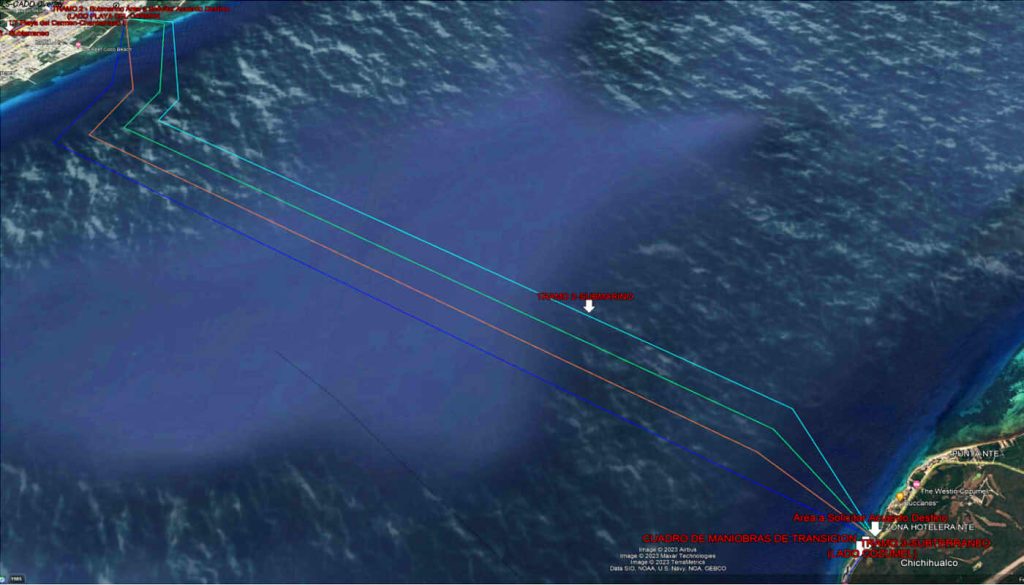

The L.T. project. CARMEN BEACH – CHANKANAAB II, as a key part of the CFE modernization strategy, plans to install a cable line of approximately 30.91 kilometers total length, what includes 30.9 kilometers of main line and an additional backup line to ensure the continuity and stability of the electricity supply. This line will use the high voltage cables from 115 kilovolts and a system frequency 60 jerks, fully considering the actual operating conditions of the Mexican electrical grid and future expansion needs.

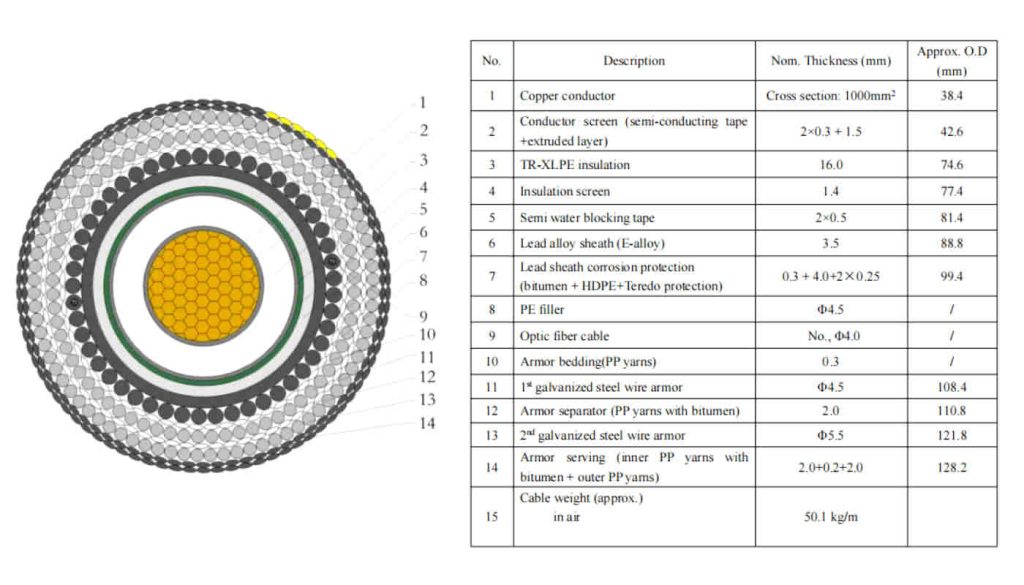

ZMS manufacturer has designed a underwater cable highly adapted to local environmental conditions for this project, employing advanced technology to ensure long-term stable operation of the cable in complex underwater environments. The cable structure is precise and, inside out, includes:

oxygen-free copper conductor: As central conductive material, Provides excellent electrical transmission efficiency and low resistance.

TR-XLPE insulation and semiconductor tape: Effectively isolates external interference, protects the driver and prevents signal leakage, improving the safety of electrical transmission.

Semi-waterproof barrier tape: Increases cable tightness, prevents water infiltration and prolongs its useful life.

Lead Alloy Case: Provides additional physical protection and effectively blocks electromagnetic interference, ensuring signal purity.

PE filling layer: Stabilizes the internal structure, ensuring cable integrity during transportation and installation.

Built-in fiber optic cable: Use fiber optic communication technology to achieve real-time monitoring and efficient data transmission.

External protection layer: Combining steel tape armor and polypropylene tape, resists physical damage and adverse environmental conditions.

Evaluation of Both Parties

The CEO and business staff of ZMS Cable visited Mexico to meet with the CFE project manager. Both parties enjoyed a pleasant conversation and reached a consensus. ZMS is providing comprehensive service for the project, ranging from design and manufacturing to transportation of the cables of various types. Currently, the project is progressing smoothly.

Mr. Ren, CEO of the ZMS, expressed in a statement of collaboration: “We are very honored to collaborate with the CFE on such an important project to update electrical infrastructure.. ZMS manufacturer is committed to applying the most advanced technology and manufacturing processes to provide Mexican citizens with a more reliable and efficient electrical service.. This collaboration not only highlights ZMS's reliable position in the cable industry, but also reflects our firm commitment to sustainable energy development worldwide.”

The CFE project manager also expressed a positive attitude towards this collaboration, highlighting that the partnership with ZMS is a key step in its modernization strategy. By incorporating advanced cable solutions, the resilience and efficiency of Mexico's electrical grid can be further improved. The CFE hopes to work together with ZMS to ensure the success of the project.

Technical Advantages of ZMS Cable Manufacturer

ZMS Cable Group owns advanced cable manufacturing equipment and rich production experience. Can produce various types of high quality cable products. Its technical advantages stand out in the following aspects:

- Advanced production equipment: ZMS has equipment advanced cable production on an international level, including submarine cable production lines, rubber cable production lines, mining cable production lines, among others, capable of meeting various cable production needs.

- Rigorous quality control: ZMS has established a complete quality management system, implementing strict quality control at each stage, from the acquisition of raw materials to the dispatch of the product, ensuring product quality meets international standards.

- Research and professional development team: ZMS has a professional R&D team that continually innovates technologically., developing new products to meet increasing customer demands.

- Complete transportation service: ZMS manufacturer offers a complete transport service. Its associated logistics team can safely and quickly deliver the well-packaged cable products to any part of the world by sea transportation., land or air.

Future perspectives

With the progress of the L.T. project. CARMEN BEACH – CHANKANAAB II, The collaboration between ZMS and the CFE not only represents a model of technological exchange between companies from two countries, but also provides valuable experience for building energy infrastructure globally.. In the future, both sides are expected to deepen cooperation in more areas, exploring together the infinite possibilities in the fields of energy and electrical networks.

As the project is implemented, the level of modernization of Mexico's electrical grid will rise even further. This also indicates that international cooperation and technological innovation are becoming important driving forces for the progress of the power supply industry..

Looking to the future, ZMS Cable Group will continue to adhere to the motto of “innovation, efficiency and reliability”, continually improving the quality of its products and services. So, will provide high-quality cable solutions to its customers worldwide and contribute to building a clean and efficient energy system.