Failures in electrical circuits are currently the main “cause” of the fires, and its causes include: the use of non-fireproof electrical cables, damage to electrical cable conductors, faults in electrical cable connections, cable insulation aging, among others, that cause fires. Therefore, to prevent fires, The choice of materials for electrical cables is especially important. Currently, the cable industry pays great attention to a new type of fire-resistant cable: ceramizable silicone cable.

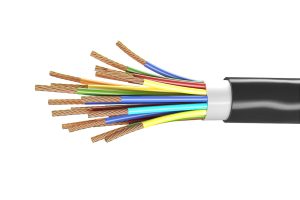

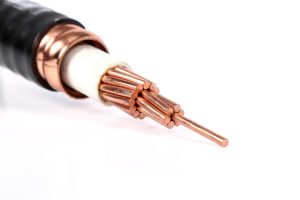

Wire insulation

Wire insulation is the process of covering an electrical conductor with a non-conductive material to prevent electrical current from escaping and causing a short circuit.. The materials used to insulate cables can be of different types, including PVC, PE, XLPE, PTFE, goma, etc.

Different types of insulated cables are used depending on the specific application and performance requirements. On this page, ZMS provides information and comparisons on the performance of cable insulation materials. Knowing this information, can more effectively select the suitable insulated cables For your application.

DC Cables XLP: Advances and Challenges in the World of Cabling

Before the XLP revolution (cross-linked polyethylene), Oil-impregnated paper-insulated cables were standard in DC projects. Hoy, Triple layer XLP DC cables have taken the lead due to their economy, Superior energy transport capacity and simplified maintenance, Outperforming traditional cables at all voltage levels.

Projected Global Sales of Eco Cables 8,020 MDD one 2023 Y 128.3 Mil MDD para 2030

In the current era, The eco cables market is experiencing constant and significant growth. According to research statistics from DIResearch, Global sales of eco cables are projected to reach 8,020 million dollars in 2023, with expectations of reaching 128.3 billion dollars for 2030.

BTTZ y YTTW: Innovation in Mineral Insulated Cables

In the world of electricity and power transmission, Constant innovation is essential to ensure safety and efficiency. In this search for continuous improvement, The invention of mineral-insulated cables has been a breakthrough in the safe transmission of electricity.. Two of the main actors in this revolution are the BTTZ y YTTW cables, offering unique features and applications in a variety of sectors.

Technical Performance of Various Electrical Cable Products

Electrical cables are an essential component in electrical infrastructure, playing a crucial role in power transmission and electricity distribution in various applications. There are several types of cables with specific technical characteristics designed to meet the needs of different environments and applications.. In this article, We will explore in detail the technical features of various electrical cable products.

Fire Resistant Cables: WTTEZ Cable,BTTZ Cable y YTTW Cable

Three cables that stand out in the field of fire protection are the WTTEZ cable, the BTTZ cable and the YTTW cable. Each of these fire resistant cables has its own unique characteristics that make them suitable for different applications.. Throughout this article, We will examine these three options in detail to help you better understand their advantages and disadvantages..

H07RN-F Cable: Versatility and Resistance for the Industry

In the industrial and construction world, Choosing the right cable is crucial to ensure safe and efficient operation. The H07RN-F cable stands out as a versatile and resistant option, widely used for mobile equipment, fixed wiring and various applications in industrial environments. Besides, Its ability to withstand harsh weather conditions and its flexibility make it a preferred choice for industry and specialty applications., like wind power.

Vulcanization of Cables: Improving the Strength and Durability of Insulation

Cable vulcanization is a crucial step in the cable manufacturing process.. The main objective of this procedure is to improve the physical and mechanical properties of the rubber used as insulation.. Vulcanization involves the crosslinking of rubber molecules into a three-dimensional network through external shearing and high temperatures.. This process gives the rubber greater tensile strength., toughness, ability to resist aging and elasticity.

Differences Between Plastic and Rubber Insulated Cables

When it comes to electrical cables, there are different types of insulation used to protect conductors and ensure safety in electrical installations. Two of the most common types of insulation are plastic and rubber.. In this article, we will explore the differences between plastic and rubber insulated cables, His composition, their uses and the advantages and disadvantages of each.

What is CPE Cable and what are its characteristics??

CPE cable refers to a cable with a chlorinated polyethylene sheath.. Due to the advantages of heat resistance, oil, ozone, aging, etc., CPE cable has been widely used in various industries.