Conductors are the main part of wire and cable products, playing a key role in the transmission of electricity or information. The structure of the driver, including its shape, cross section, composition and material, Depends on product function and application needs. Now let's explore the different types of conductors with special shapes in cables, its advantages and disadvantages, and how the associated challenges can be mitigated.

electricity conductor

The electricity driver is made of materials that have low electric resistance and high conductivity. The most used metals for the manufacture of cable conductors are copper and aluminum.

Copper is one of the most used metals in the manufacture of electrical conductors due to its high conductivity and corrosion resistance. Besides, copper is a malleable and easy to work metal. It is ideal for use in cable manufacturing. Aluminum is another material commonly used for driver's manufacturing, especially for high voltage transmission lines. Aluminum is a lighter metal than copper. It is ideal for use in long -distance transmission lines, where cable weight is an important factor to consider.

Aluminum or copper and galvanized steel alloys are also used as an electricity conductor, depending on the specific needs of each application. ZMS offers information and news about cable conductors, including technical information on the comparison of different drivers, The use of drivers in different applications, The driver market, etc.

How to Determine the Cross-sectional Area of Electrical Conductors?

In electrical design and technical reforms, scientific selection of cross-sectional area of electrical conductors is crucial. Experienced electricians will calculate the current according to the electrical load to decide the cross-sectional area of the wires.. There are also some electricians who will choose the cross-sectional area of the wires based on a mnemonic.. Today ZMS will share with you a scientific and simple method to select the cross-sectional area of cables.

Corrosion in Copper and Aluminum Cables

The principle of corrosion of copper cables and aluminum cables refers to a chemical process that occurs when these cables come into contact with the specific environment, causing rust and damage to the metal surface. These chemical processes mainly include two mechanisms: electrochemical corrosion and chemical corrosion.

What are the Differences between AAAC Cables and Copper Cables??

In the power distribution system, Power cables are the main material used to transport electricity. Currently, The most common electrical cables are those with a copper core and those made of aluminum alloy. Does 40 years, cable industry developed AA8000 series aluminum alloy as conductive material. Currently, more than 90% of municipal projects, civilians, Industrial and commercial in the United States use AAAC cables (aluminum alloy conductors).

Aerial Aluminum Conductor Market up to 2032

The market for aerial aluminum conductors is an essential component of the electric power transmission and distribution industry.. It is made up of products such as insulated conductors, bare overhead conductors and accessories used in the construction and maintenance of overhead transmission lines. In recent years, this market has experienced steady growth and is expected to maintain a compound annual growth rate (CAGR) of 4% during the forecast period from 2022 until 2032. It is expected to reach USD 1259.4 million in that period.

The Dawn of Room Temperature Superconductivity: Implications and Challenges

In the 25 July 2023, A groundbreaking discovery by Korean researchers shook the scientific community, announcing the successful synthesis of the world's first superconductor at room temperature and room pressure, the crystal structure of modified lead phosphorsilicate (LK-99). This achievement could revolutionize various industries, offering unprecedented possibilities for power transmission, transport, medicine and scientific research. Nevertheless, further verification is required to fully understand the implications of this remarkable breakthrough.

Exploring Cable Conductor Types

The types of cable conductors are classified according to their material, its shape and use. Different applications require the use of different types of conductors. Now, ZMS walks you through the various electrical conductors.

Discovering Copper Clad Aluminum Cable in Detail

Copper clad aluminum cable is an innovative solution that seeks to balance the cost and performance of cables in a context of scarce copper resources.. This type of cable is characterized by having a main aluminum conductor covered by a layer of copper on the outside.. The introduction of this technology has made it possible to take advantage of the copper conductor, as its excellent electrical performance, while reducing the cost and weight associated with using aluminum as the primary material.

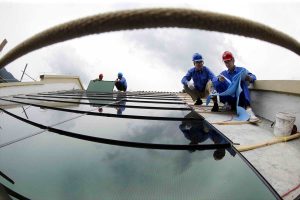

Power Generator Glass: An Emerging Force in Green Technology

in march of 2023, CNBM (Chengdu) Optoelectronic Materials Co., Ltd. received the China Industry Award for outstanding achievement in independent innovation of a power generation technology. This technology has the ability to turn a piece of ordinary insulating glass into a conductive material, generating electricity. This pioneering innovation opens a new path for green energy development by enabling power generation from sunlight. Hoy, let ZMS take you on a journey to explore the wonderful world of power generating glass.

Metallic Conductors: Everything you need to know

Metallic conductors are materials used in the transmission of electrical energy.. Currently, the most common metallic conductors are copper, the aluminum, gold and silver. Considering the price and conductivity, the most used is the copper conductor.