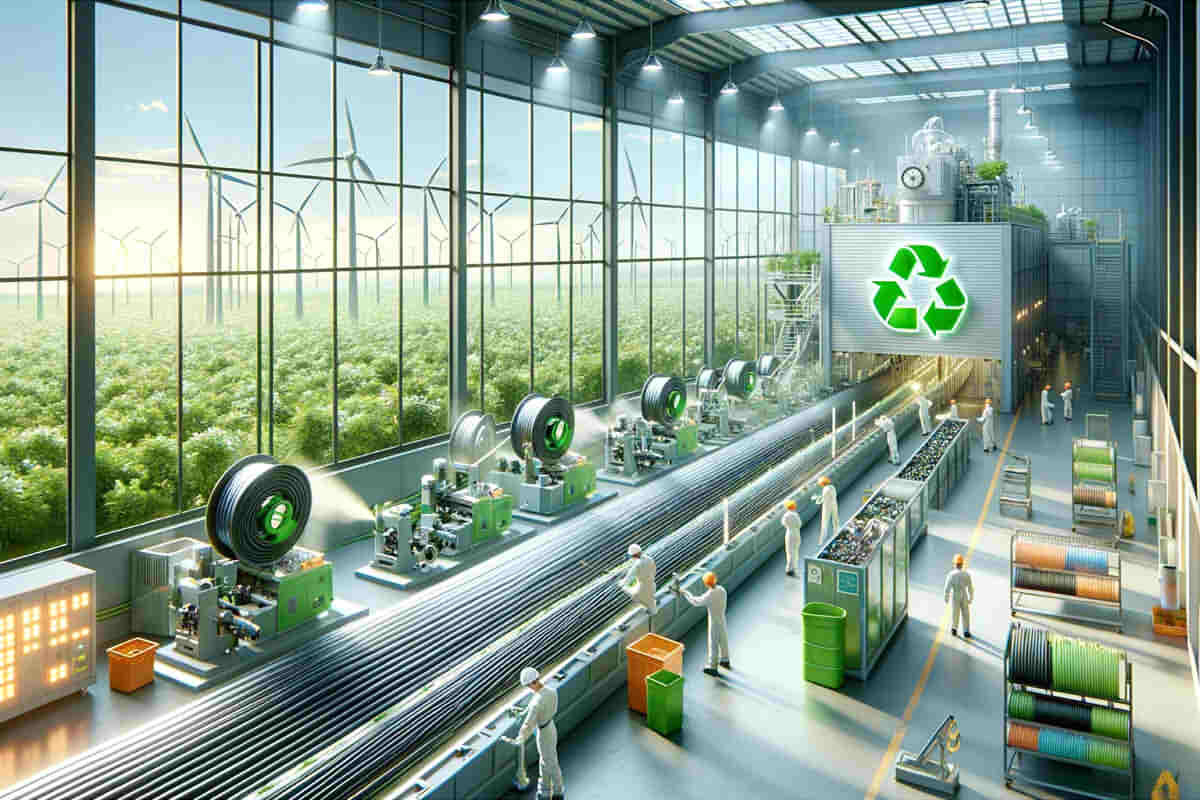

As environmental problems become increasingly evident, all industries are actively exploring ways to achieve sustainable development. The wire and cable industry also faces the urgent challenge of how to save energy and reduce pollution during the production process.. The green transformation of electrical cable manufacturing is a production method aimed at environmental protection, that requires reducing or eliminating environmental pollution during the production process, improve resource use efficiency and promote clean production.

Green manufacturing helps cable companies to reduce production costs, improve product quality, increase competitiveness in the market, establish a good corporate image and achieve high-quality development in the manufacturing industry.

With the gradual advancement of the construction of new electrical systems, demand and requirements for cables are also increasing. ZMS Cable has been constantly exploring greener manufacturing methods to achieve green production of various cable products..

Green Manufacturing

The manufacturing of green electrical cables includes: green production technologies, green production equipment and green production processes.

Green production technologies

Always maintain the basic principles of environmental protection through technological innovation, including emissions reduction technologies, energy saving technologies, water resources saving technologies, technologies for comprehensive use of solid waste, etc. Within allowable cost limits, actively develop or introduce production technologies ecological cables and energy efficient to enhance technological advantage.

Green production equipment

Actively equip yourself with green production equipment, automated production lines and smart manufacturing systems. ZMS Cable is actively building smart workshops, with a digital command center at the core, solving problems in the production process in a visualized and digital way. Besides, The factory has introduced advanced braiding machines 48 spindles, significantly increasing production efficiency.

Green production processes

They include clean production processes, low carbon manufacturing processes, recycling processes, etc. Manufacturing electrical cables can generate waste gases, waste plastics, waste metals, etc. If this waste is discharged directly without treatment, will cause serious environmental impact. Therefore, Green production processes require cable companies to establish scientific waste treatment systems, adopt non-harmful treatment methods, reduce waste emissions and improve resource use efficiency. At the same time, optimize production processes to reduce energy consumption and emissions during the production process, improving production efficiency.

Make Green

Making green means that cable products produced must be ecological, safe and efficient, meeting green consumption needs. Specifically, This involves addressing the following aspects:

Selection of green materials

The primary materials of cable products should preferably be environmentally friendly, renewable and recyclable, reducing environmental impact. At the same time, The production process of cable products should avoid the use of toxic and harmful materials, ensuring the safety and ecology of products. For example, polypropylene cables, lead free cables, low smoke and halogen cables, recyclable cables, etc. Los ZMS flame retardant cables They use mineral insulating material that ceramizes at high temperatures, with a low-smoke, halogen-free outer shell, offering excellent performance in terms of fire resistance and environmental protection.

Use of clean energy

Actively promote the use of clean energy and energy-saving technologies, such as solar and wind energy, to reduce the cable industry's dependence on fossil fuels. Strengthen the research and application of energy-saving technologies to improve energy use efficiency during the cable production process. Improve energy management to reduce energy consumption in the cable production process, reducing production costs.

Green design

The design of cable products should consider environmental protection factors, energy saving and safety, reducing unnecessary waste and pollution. For example, reasonably design the wire structure and size to minimize material waste; Optimize cable conduction performance to reduce electrical energy loss.

Green packaging and transportation

Packaging and transportation of cable products must also consider environmental factors. Use recyclable and biodegradable packaging materials to reduce the impact of packaging waste on the environment; optimize transportation methods to reduce energy consumption and emissions during transportation.

Recycling and reuse of cables and wires

This includes the reuse of scrap cable and the remanufacturing of cable products.. Recirculation is essential to achieve effective sustainable development. Establish a complete collection system, cable waste sorting and treatment to improve waste recycling rate. Develop new technologies to increase the reuse value of discarded cables, reducing environmental pollution. Strengthen waste cable management to prevent messy disposal and accumulation, that could contaminate the environment.

ZMS is committed to green transformation

In summary, The green transformation of the cable industry is a systematic project that requires companies to address multiple aspects to comprehensively improve green manufacturing capacity and “make green”. Only in this way, Intense market competitions can be overcome, ensuring sustainable development.

ZMS Cable has already actively committed to the green transformation of the industry. ZMS Cable is deepening its commitment to sustainability through a strategy that encompasses product and process innovation, energy efficiency, and strong collaboration with all stakeholders. This strategy includes the development of more sustainable and recyclable materials for cables, improving energy efficiency in production through the adoption of advanced technologies and investment in renewable energy sources.

Besides, The company is strengthening its ties with suppliers and customers to promote ecological practices throughout the value chain, ensuring that your efforts towards sustainability are inclusive and extensive. This approach not only seeks to reduce the carbon footprint of ZMS Cable and improve its competitiveness in the market, but also encourage broader positive change within the industry and among consumers.